Product Description

Product Description

| Business type | Factory/manufacturer |

|

Service |

CNC machining |

| Turning and milling | |

| CNC turning | |

| OEM parts | |

|

Material |

(1) Aluminum:AL 6061-T6,6063,7075-T |

| (2)Stainless steel:303,304,316L,17-4(SUS630) | |

| (3)Steel:4140,Q235,Q345B,20#,45# | |

| (4)Titanium:TA1,TA2/GR2,TA4/GR5,TC4,TC18 | |

| (5)Brass:C36000(HPb62),C37700(HPb59),C26800(H68) | |

| (6)Copper, bronze, magnesium alloy, Delan, POM, acrylic, PC, etc. | |

| Service | OEM/ODM avaliable |

|

Finish |

Sandblasting, anodizing, Blackenning, zinc/Nickl plating, Poland |

| Powder coating, passivation PVD plating titanium, electrogalvanization | |

| Chrome plating, electrophoresis, QPQ | |

| Electrochemical polishing, chrome plating, knurling, laser etching Logo | |

| Major equipment | CNC machining center (milling machine), CNC lathe, grinding machine |

| Cylindrical grinding machine, drilling machine, laser cutting machine | |

| Graphic format | STEP, STP, GIS, CAD, PDF, DWG, DXF and other samples |

| Tolerance | +/-0.003mm |

| Surface roughness | Ra0.1~3.2 |

| Inspection | Complete testing laboratory with micrometer, optical comparator, caliper vernier, CMM |

| Depth caliper vernier, universal protractor, clock gauge, internal Celsius gauge |

Detailed Photos

Product Parameters

| MATERIAL AVAILABLE | |||||

| Aluminum | Stainless Steel | Brass | Copper | Plastic | Iron |

| AL2571 | SS201 | C22000 | C15710 | POM | Q235 |

| ALA380 | SS301 | C24000 | C11000 | PEEK | Q345B |

| AL5052 | SS303 | C26000 | C12000 | PVC | 1214 / 1215 |

| AL6061 | SS304 | C28000 | C12200 | ABS | 45# |

| AL6063 | SS316 | C35600 | etc. | Nylon | 20# |

| AL6082 | SS416 | C36000 | PP | 4140 / 4130 | |

| AL7075 | etc. | C37000 | Delrin | 12L14 | |

| etc. | etc. | etc. | etc. | ||

| SURFACE TREATMENT | |||||

| Aluminum Parts | Stainless Steel Parts | Steel Parts | Brass Parts | ||

| Clear Anodized | Polishing | Zinc Plating | Nickel Plating | ||

| Color Anodized | Passivating | Oxide black | chrome plating | ||

| Sandblast Anodized | Sandblasting | Nickel Plating | Electrophoresis black | ||

| Chemical Film | Laser engraving | Powder Coated | Powder coated | ||

| Brushing | Electrophoresis black | Heat treatment | Gold plating | ||

| Polishing | Oxide black | Chrome Plating | etc. | ||

| Chroming | etc | etc | |||

| etc | |||||

| TOLERANCE | |||||

| The smallest tolerance can reach +/-0.001mm or as per drawing request. | |||||

| DRAWING FORMAT | |||||

| PFD | Step | Igs | CAD | Solid | etc |

Packaging & Shipping

Company Profile

HangZhou Shinemotor Co.,Ltd located in HangZhou City, ZheJiang Province of China.

Mainly specializes in developing, manufacturing and selling all kinds of customized metal and plastic parts.

Our factory pass SGS, ISO9001/ ISO9001/ ISO14001 verification, parts can be widely used in the fields of automobile,

medical instruments, electronic communications, industrial and consumer applications and so on.

We have introduced a series of advanced and high performance production equipment imported from Japan and ZheJiang :

High precision cnc lathes, 5/6 axis cnc machining centers, plane grinding & centerless grinding machines,

stamping machines, wire cut machines, EDM and many other high-precision CNC equipment.

Our inspection equipment includes: projector, 2D, 2.5D, CMM, hardness testing machine, tool microscope, etc.

We dedicated to developing and producing kinds of brass, aluminum, steel, stainless steel

And plastic machining parts, stamping parts, and also CZPT design and manufacturing.

We firmly hold the concept of ” customer is the first, honesty is the basic, accrete win-win “.

Dedicated to providing you with high-quality products and excellent service!

We sincerely look forward to creating a better future by mutually beneficial cooperation with you.

FAQ

1. Are you a factory or a trading company?

A: We are a factory which has been specialized in cnc machining & automatic manufacturing for more than 10 years.

2. Where is your factory and how can I visit it?

A: Our factory is located in HangZhou city and you can get more detailed information by browsing our website.

3. How long can I get some samples for checking and what about the price?

A: Normally samples will be done within 1-2 days (automatic machining parts) or 3-5 day (cnc machining parts).

The sample cost depends on all information (size, material, finish, etc.).

We will return the sample cost if your order quantity is good.

4. How is the warranty of the products quality control?

A: We hold the tightend quality controlling from very begining to the end and aim at 100% error free.

5.How to get an accurate quotation?

♦ Drawings, photos, detailed sizes or samples of products.

♦ Material of products.

♦ Ordinary purchasing quantity.

♦ Quotation within 1~6 hours

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

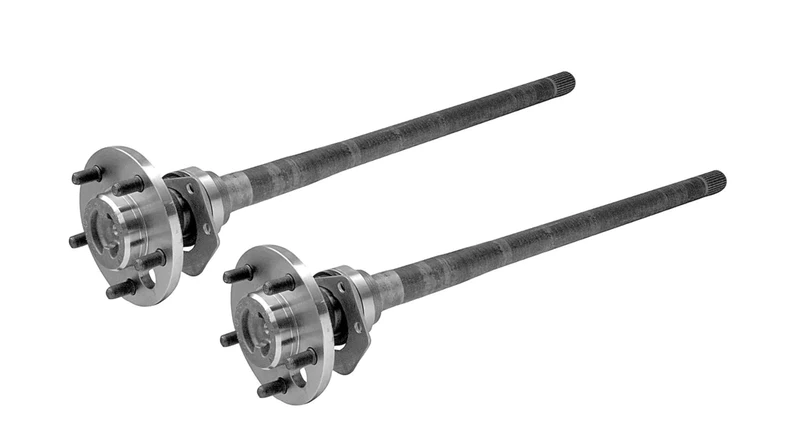

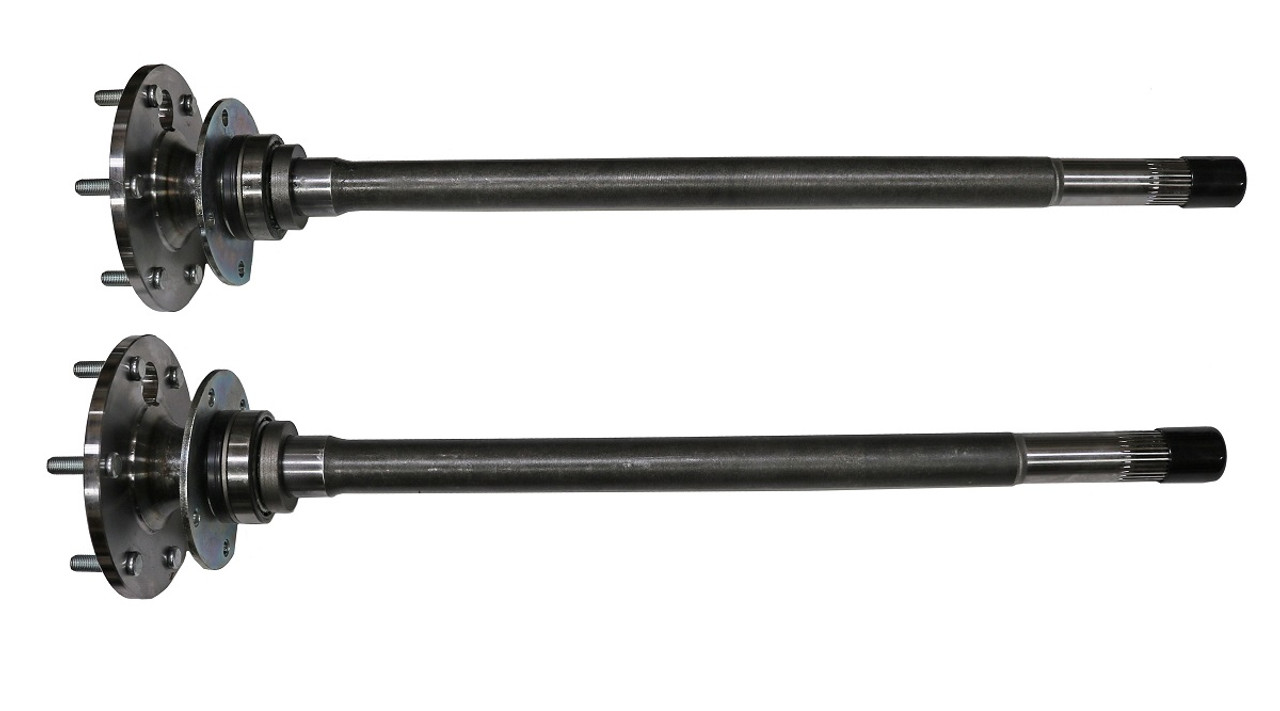

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the impact of axle shaft materials on weight and strength?

The choice of material for axle shafts has a significant impact on both weight and strength characteristics. Different materials offer varying levels of strength-to-weight ratios, which can influence the overall performance and durability of the axle shafts. Here’s an explanation of how axle shaft materials affect weight and strength:

- Steel: Steel is a commonly used material for axle shafts due to its high strength and durability. Steel axle shafts are known for their excellent load-bearing capacity and resistance to bending and torsional forces. However, steel is relatively heavy compared to other materials, which can contribute to increased overall weight of the vehicle. The weight of steel axle shafts can affect the vehicle’s fuel efficiency and handling characteristics.

- Alloy Steel: Alloy steel is a type of steel that has been mixed with other elements to enhance specific properties. By adding elements such as chromium, molybdenum, or nickel, alloy steel can achieve improved strength and hardness compared to traditional steel. This allows for the production of lighter and stronger axle shafts compared to conventional steel, providing a balance between weight reduction and structural integrity.

- Aluminum: Aluminum is a lightweight material known for its excellent strength-to-weight ratio. When used in axle shafts, aluminum can significantly reduce the weight of the component, which can lead to benefits such as improved fuel efficiency and handling. However, aluminum axle shafts may not be as strong as steel shafts and can be more susceptible to bending or deformation under high loads or extreme conditions.

- Composite Materials: Composite materials, such as carbon fiber reinforced polymers (CFRP), are increasingly being explored for axle shaft applications. CFRP composites offer high strength and light weight, making them attractive for weight reduction purposes. These materials can provide comparable or even superior strength compared to steel while significantly reducing the overall weight of the axle shafts. However, composite materials often come with higher production costs and may require specialized manufacturing techniques.

Overall, the choice of axle shaft material involves a trade-off between weight reduction and strength requirements. Steel offers excellent strength but comes with higher weight, while materials like aluminum and composites offer weight savings at the expense of some strength characteristics. The selection of the most suitable material depends on various factors, including the vehicle’s intended use, load requirements, cost considerations, and desired performance attributes.

In summary, the impact of axle shaft materials on weight and strength is significant. Steel provides high strength but adds weight, alloy steel offers a balance between strength and weight, aluminum reduces weight but may sacrifice some strength, and composite materials provide strength and weight advantages but at potentially higher costs. Manufacturers consider these factors when selecting axle shaft materials to achieve the desired balance of weight reduction, strength, and overall performance in vehicles.

Can you describe the maintenance and repair considerations for axle shafts?

Maintenance and repair of axle shafts are essential to ensure the proper functioning and longevity of a vehicle’s drivetrain. Regular maintenance and timely repairs can help prevent costly damages and maintain optimal performance. Here’s a detailed explanation of the maintenance and repair considerations for axle shafts:

Maintenance Considerations:

To keep the axle shafts in good condition, the following maintenance practices are recommended:

- Inspections: Regularly inspect the axle shafts for signs of damage, such as cracks, bends, or excessive wear. Inspect the CV joints, bearings, seals, and retaining devices for leaks, deterioration, or looseness. Pay attention to any unusual noises, vibrations, or fluid leaks that may indicate potential issues.

- Lubrication: Ensure proper lubrication of the axle shafts, CV joints, and bearings as recommended by the vehicle manufacturer. Lubrication helps reduce friction, prevent excessive wear, and extend the lifespan of the components. Check the lubricant levels and quality during routine maintenance and top up or replace the lubricant as needed.

- Seal Protection: Inspect the seals around the axle shafts for damage or leaks. Damaged seals can allow contaminants, such as dirt, moisture, and debris, to enter the axle assembly, leading to premature wear and potential failure of the components. Replace damaged seals promptly to maintain proper protection.

- Boot Inspection: If the axle shafts have constant velocity (CV) joints, inspect the protective boots regularly. The boots cover the CV joints and keep them protected and lubricated. Look for any signs of cracks, tears, or leaking grease. Damaged boots should be replaced promptly to prevent dirt and moisture from entering the CV joints.

- Wheel Bearing Maintenance: If the axle shafts incorporate wheel bearings, follow the manufacturer’s recommendations for bearing maintenance. This may include periodic inspection, cleaning, re-greasing, or replacement of the wheel bearings to ensure smooth rotation and prevent excessive wear.

Repair Considerations:

If axle shaft issues are identified through inspections or during routine maintenance, the following repair considerations should be taken into account:

- Evaluation and Diagnosis: When encountering axle shaft problems, it’s important to accurately diagnose the issue before proceeding with repairs. This may involve a visual inspection, listening for abnormal noises, performing tests, or seeking professional assistance to identify the specific cause of the problem.

- Component Replacement: Depending on the nature and severity of the issue, repair options may vary. In some cases, replacing individual components such as CV joints, bearings, or seals may be sufficient. However, if the axle shaft itself is damaged or worn beyond repair, it may be necessary to replace the entire axle shaft assembly.

- Professional Expertise: Axle shaft repairs can be complex and require specialized knowledge and tools. It is often recommended to seek the assistance of a qualified mechanic or technician who has experience working with axle shafts. They can provide proper diagnosis, perform repairs accurately, and ensure the correct installation of components.

- Quality Parts: When replacing axle shaft components or the entire assembly, it is crucial to use high-quality parts that meet or exceed the manufacturer’s specifications. Using genuine or reputable aftermarket parts can help ensure proper fit, performance, and durability.

- Alignment and Calibration: After axle shaft repairs or replacements, it may be necessary to perform wheel alignment and calibration procedures to ensure proper suspension geometry, wheel balance, and drivetrain synchronization. This helps maintain vehicle stability, tire wear, and overall performance.

By following these maintenance practices and considering the appropriate repair steps, owners can help keep axle shafts in optimal condition, minimize the risk of failure, and ensure the reliable operation of the vehicle’s drivetrain.

What are the components of an axle shaft assembly and their functions?

An axle shaft assembly consists of several components that work together to facilitate the transmission of power from the differential to the wheels. Each component plays a specific role in ensuring efficient power transfer and supporting the functionality of the axle shaft assembly. Here are the main components and their functions:

1. Axle Shaft:

The axle shaft itself is the main component of the assembly. It is a long, cylindrical shaft that connects the differential or transaxle to the wheels. The primary function of the axle shaft is to transmit rotational power from the differential to the wheels, enabling them to rotate and propelling the vehicle forward or backward.

2. Differential Side Gears or Output Shafts:

The axle shaft assembly is connected to the differential through side gears or output shafts. These are gear-like components that are part of the differential mechanism. The side gears or output shafts engage with the axle shafts, providing a solid mechanical connection. They allow the rotational force from the differential to be transmitted to the axle shafts, initiating power transfer to the wheels.

3. Constant Velocity (CV) Joints:

In many modern vehicles, especially those with front-wheel drive or independent suspension systems, the axle shaft assembly incorporates constant velocity (CV) joints. CV joints allow for smooth power transfer and accommodate changes in axle angle and length due to suspension movement and steering. They provide flexibility and reduce vibrations during power transmission. CV joints consist of inner and outer joints with ball bearings and protective boots filled with grease to maintain lubrication and prevent contamination.

4. Wheel Hubs:

At the outer ends of the axle shaft assembly, wheel hubs are attached. Wheel hubs serve as the connection points for the wheels. They provide a mounting surface for the wheels and ensure proper alignment and rotation. The axle shafts transmit the rotational power from the differential to the wheel hubs, causing the wheels to rotate. Wheel hubs often incorporate bearings to allow smooth rotation and reduce friction.

5. Bearings:

Bearings are crucial components within the axle shaft assembly. They support the rotating motion of the axle shafts and the wheel hubs. The bearings reduce friction and allow the axle shafts and wheel hubs to rotate freely. They are typically designed to withstand the forces and loads encountered during vehicle operation and contribute to smooth and efficient power transmission.

6. Seals and Retaining Devices:

To prevent the entry of contaminants and retain lubrication, seals are used in the axle shaft assembly. Seals are placed at various points along the assembly to protect the bearings, CV joints, and other critical components from dirt, moisture, and debris. Additionally, retaining devices such as circlips or snap rings are used to secure the axle shafts, CV joints, or bearings within their respective housings, ensuring proper alignment and preventing unintended disassembly.

These are the key components typically found in an axle shaft assembly. The combination of these components allows for effective power transmission, smooth rotation, support for the wheels, and protection of critical parts, ensuring the overall functionality and longevity of the axle shaft assembly.

editor by CX 2024-04-15

China OEM China Factory Custom Axle Gear Spline Yacht Motor Shaft axle arm

Product Description

Product Description

Product Parameters

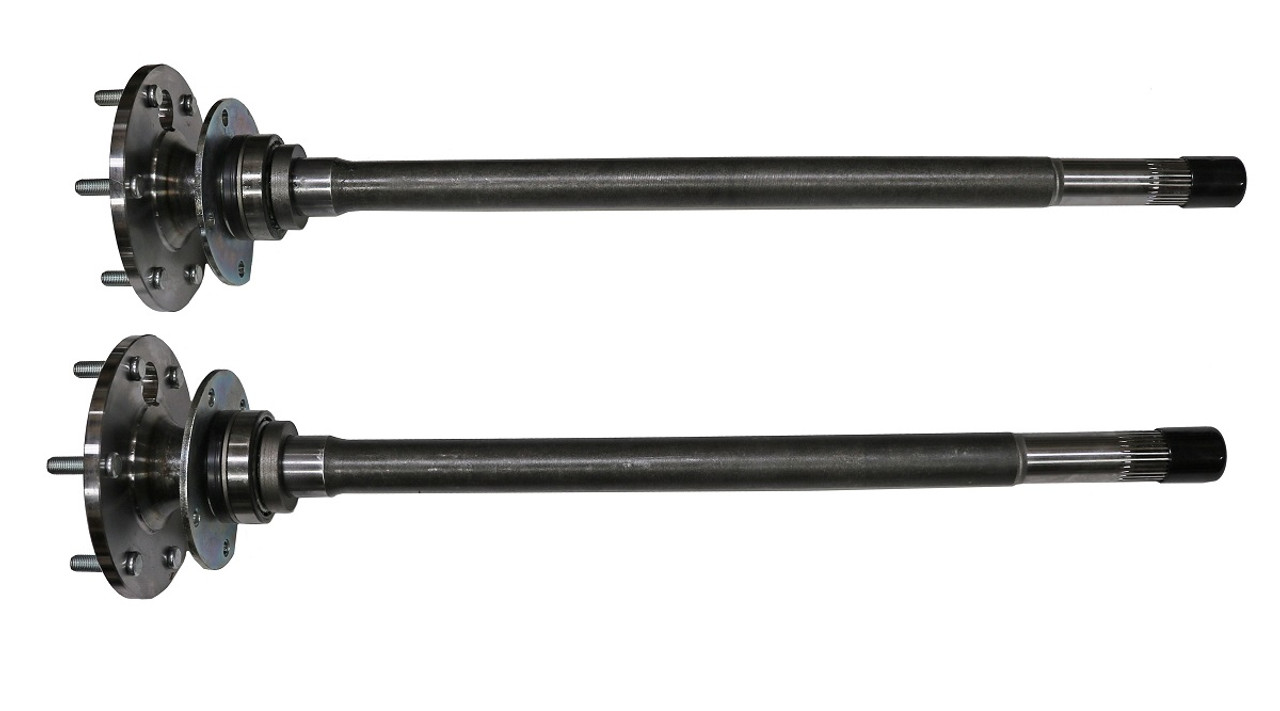

| Item | Spur Gear Axle Shaft |

| Material | 4140,4340,40Cr,42Crmo,42Crmo4,20Cr,20CrMnti, 20Crmo,35Crmo |

| OEM NO | Customize |

| Certification | ISO/TS16949 |

| Test Requirement | Magnetic Powder Test, Hardness Test, Dimension Test |

| Color | Paint , Natural Finish ,Machining All Around |

| Material | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Steel: Carbon Steel,Middle Steel,Steel Alloy,etc. | |

| Stainess Steel: 303/304/316,etc. | |

| Copper/Brass/Bronze/Red Copper,etc. | |

| Plastic:ABS,PP,PC,Nylon,Delrin(POM),Bakelite,etc. | |

| Size | According to Customer’s drawing or samples |

| Process | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Cutting,etc. |

| Tolerance | ≥+/-0.03mm |

| Surface Treatment | (Sandblast)&(Hard)&(Color)Anodizing,(Chrome,Nickel,Zinc…)Plating,Painting,Powder Coating,Polishing,Blackened,Hardened,Lasering,Engraving,etc. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Available |

| Packing | Spline protect cover ,Wood box ,Waterproof membrane; Or per customers’ requirements. |

Our Advantages

Why Choose US ???

1. Equipment :

Our company boasts all necessary production equipment,

including Hydraulic press machines, Japanese CNC lathe (TAKISAWA), Korean gear hobbing machine (I SNT), gear shaping machine, machining center, CNC grinder, heat treatment line etc.

2. Processing precision:

We are a professional gear & gear shafts manufacturer. Our gears are around 6-7 grade in mass production.

3. Company:

We have 90 employees, including 10 technical staffs. Covering an area of 20000 square meters.

4. Certification :

Oue company has passed ISO 14001 and TS16949

5.Sample service :

We provide free sample for confirmation and customer bears the freight charges

6.OEM service :

Having our own factory and professional technicians,we welcome OEM orders as well.We can design and produce the specific product you need according to your detail information

Cooperation Partner

Company Profile

Our Featured Products

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

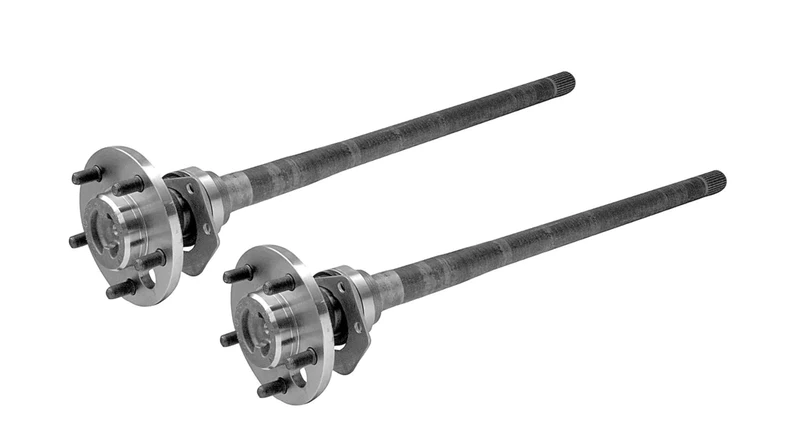

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Axis Shape: | Straight Shaft |

| Appearance Shape: | Round |

| Rotation: | Cw |

| Yield: | 5, 000PCS / Month |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you explain the impact of axle shaft materials on weight and strength?

The choice of material for axle shafts has a significant impact on both weight and strength characteristics. Different materials offer varying levels of strength-to-weight ratios, which can influence the overall performance and durability of the axle shafts. Here’s an explanation of how axle shaft materials affect weight and strength:

- Steel: Steel is a commonly used material for axle shafts due to its high strength and durability. Steel axle shafts are known for their excellent load-bearing capacity and resistance to bending and torsional forces. However, steel is relatively heavy compared to other materials, which can contribute to increased overall weight of the vehicle. The weight of steel axle shafts can affect the vehicle’s fuel efficiency and handling characteristics.

- Alloy Steel: Alloy steel is a type of steel that has been mixed with other elements to enhance specific properties. By adding elements such as chromium, molybdenum, or nickel, alloy steel can achieve improved strength and hardness compared to traditional steel. This allows for the production of lighter and stronger axle shafts compared to conventional steel, providing a balance between weight reduction and structural integrity.

- Aluminum: Aluminum is a lightweight material known for its excellent strength-to-weight ratio. When used in axle shafts, aluminum can significantly reduce the weight of the component, which can lead to benefits such as improved fuel efficiency and handling. However, aluminum axle shafts may not be as strong as steel shafts and can be more susceptible to bending or deformation under high loads or extreme conditions.

- Composite Materials: Composite materials, such as carbon fiber reinforced polymers (CFRP), are increasingly being explored for axle shaft applications. CFRP composites offer high strength and light weight, making them attractive for weight reduction purposes. These materials can provide comparable or even superior strength compared to steel while significantly reducing the overall weight of the axle shafts. However, composite materials often come with higher production costs and may require specialized manufacturing techniques.

Overall, the choice of axle shaft material involves a trade-off between weight reduction and strength requirements. Steel offers excellent strength but comes with higher weight, while materials like aluminum and composites offer weight savings at the expense of some strength characteristics. The selection of the most suitable material depends on various factors, including the vehicle’s intended use, load requirements, cost considerations, and desired performance attributes.

In summary, the impact of axle shaft materials on weight and strength is significant. Steel provides high strength but adds weight, alloy steel offers a balance between strength and weight, aluminum reduces weight but may sacrifice some strength, and composite materials provide strength and weight advantages but at potentially higher costs. Manufacturers consider these factors when selecting axle shaft materials to achieve the desired balance of weight reduction, strength, and overall performance in vehicles.

What are the advantages of using high-performance or heavy-duty axle shafts?

Using high-performance or heavy-duty axle shafts can offer several advantages in terms of strength, durability, and performance. These specialized axle shafts are designed to handle increased torque loads, provide improved power delivery, and withstand the demands of challenging applications. Here’s a detailed explanation of the advantages of using high-performance or heavy-duty axle shafts:

- Increased Strength: High-performance or heavy-duty axle shafts are typically constructed from stronger materials, such as chromoly steel or alloy steel. These materials offer higher tensile and yield strength compared to standard axle shafts. The increased strength allows the shafts to handle higher torque loads without deformation or failure, providing enhanced reliability and durability.

- Improved Power Delivery: High-performance axle shafts are designed to provide more efficient power delivery from the drivetrain to the wheels. The enhanced strength and rigidity of these shafts minimize power loss due to torsional flex, ensuring that a greater percentage of the torque generated by the engine reaches the wheels. This results in improved acceleration, better throttle response, and enhanced overall performance.

- Enhanced Torsional Rigidity: Heavy-duty axle shafts are often engineered with increased torsional rigidity. This means they have reduced torsional flex or twisting under load. The improved torsional rigidity helps maintain consistent power transfer to the wheels, especially during high-torque situations or aggressive driving maneuvers. It contributes to better traction and stability, particularly in performance-oriented or off-road applications.

- Increased Durability: High-performance or heavy-duty axle shafts are designed to withstand the demands of challenging applications. They are engineered to handle increased loads, higher rotational speeds, and more extreme operating conditions. By providing greater durability, these axle shafts can withstand off-road obstacles, heavy payloads, or aggressive driving without premature wear or failure.

- Improved Off-Road Capability: High-performance or heavy-duty axle shafts are particularly beneficial in off-road applications. They can handle the additional stresses and forces encountered during off-road driving, such as uneven terrain, rock crawling, or high-speed desert runs. With increased strength and durability, these axle shafts reduce the risk of breakage, allowing off-road enthusiasts to explore challenging terrains with more confidence.

- Support for Vehicle Modifications: High-performance or heavy-duty axle shafts are often used in vehicles with significant modifications, such as increased engine power, larger tires, or suspension upgrades. These axle shafts can accommodate the additional torque loads and provide the necessary strength and reliability to support the modified drivetrain and suspension components.

It’s important to note that the advantages of high-performance or heavy-duty axle shafts are most noticeable in applications where the vehicle is subjected to increased torque loads, extreme conditions, or performance-oriented driving. In everyday driving scenarios with standard vehicles, the benefits may be less pronounced.

When considering high-performance or heavy-duty axle shafts, it’s crucial to ensure compatibility with other drivetrain components, such as the differential, wheel hubs, and braking system. Additionally, professional installation by experienced technicians is recommended to ensure proper fitment and compatibility.

Overall, high-performance or heavy-duty axle shafts offer increased strength, improved power delivery, enhanced durability, and better performance characteristics, making them a valuable upgrade for specific applications where increased performance, reliability, and off-road capability are desired.

Are there different axle shaft designs for rear-wheel drive and front-wheel drive vehicles?

Yes, rear-wheel drive (RWD) and front-wheel drive (FWD) vehicles typically employ different axle shaft designs to accommodate their respective drivetrain configurations. The axle shafts in RWD and FWD vehicles differ in their construction, orientation, and connection to the wheels. Here’s a detailed explanation of the axle shaft designs used in RWD and FWD vehicles:

Rear-Wheel Drive (RWD) Vehicles:

In RWD vehicles, the engine’s power is transmitted to the rear wheels through the drivetrain components. The axle shaft design in RWD vehicles is commonly referred to as a solid axle or full-floating axle. Here are the key characteristics of RWD axle shafts:

- Rigid Shaft: RWD axle shafts are typically solid and rigid, connecting the differential directly to each rear wheel. They are designed to handle high torque loads and provide robustness, making them suitable for heavy-duty applications.

- Single Connection: Each rear wheel has its own dedicated axle shaft, which connects directly to the wheel hub. The axle shaft transfers power to the wheel, enabling it to rotate.

- Support and Power Transfer: RWD axle shafts support the weight of the vehicle and transmit torque from the differential to the wheels. They facilitate smooth power delivery and enable the rear wheels to propel the vehicle forward or backward.

- Less Articulation: Since RWD vehicles typically have a solid rear axle, the axle shafts have limited articulation compared to FWD vehicles. This design simplifies the construction but may result in reduced suspension flexibility and a harsher ride quality.

Front-Wheel Drive (FWD) Vehicles:

In FWD vehicles, the engine’s power is transmitted to the front wheels through the drivetrain components. FWD axle shafts are commonly known as half shafts or CV axles (constant velocity axles). Here are the main characteristics of FWD axle shafts:

- Compact and Lightweight: FWD axle shafts are typically lighter and more compact than RWD axle shafts. They are designed to accommodate the space limitations in the front-wheel-drive layout.

- Constant Velocity (CV) Joints: FWD axle shafts incorporate constant velocity (CV) joints, which allow for flexibility and rotation at various angles. CV joints compensate for the changing length and angle of the axle shafts during suspension movement and steering.

- Transverse Orientation: FWD axle shafts are positioned transversely across the vehicle, connecting the differential or transaxle to the front wheels. This orientation allows for efficient power transfer and space utilization in FWD vehicles.

- Support and Power Transfer: FWD axle shafts support the weight of the vehicle and transmit torque from the differential or transaxle to the front wheels. They enable the front wheels to rotate and provide the driving force for vehicle movement.

- Increased Articulation: FWD axle shafts have greater articulation capabilities due to the need to accommodate suspension movement and steering angles. The CV joints allow the axle shafts to flex and rotate, ensuring smooth power delivery even when the wheels are turned or the suspension is compressed.

These axle shaft designs in RWD and FWD vehicles are tailored to the specific requirements and configurations of each drivetrain layout. They optimize power transmission, support the wheels, and ensure efficient operation based on the unique characteristics of rear-wheel drive and front-wheel drive systems.

editor by CX 2024-04-10

China factory China Factory Custom Precision Carbon Cue Shaft Worm Main Spindle Servo DC Motor Shaft Drive Axle Shaft axle arm

Product Description

Product Description

|

Company Profile

HangZhou Xihu (West Lake) Dis. Machinery Manufacture Co., Ltd., located in HangZhou, “China’s ancient copper capital”, is a “national high-tech enterprise”. At the beginning of its establishment, the company adhering to the “to provide clients with high quality products, to provide timely service” concept, adhere to the “everything for the customer, make customer excellent supplier” for the mission.

Certifications

Q: Where is your company located ?

A: HangZhou ZheJiang .

Q: How could l get a sample?

A: Before we received the first order, please afford the sample cost and express fee. we will return the sample cost back

to you within your first order.

Q: Sample time?

A: Existing items: within 20-60 days.

Q: Whether you could make our brand on your products?

A: Yes. We can print your Logo on both the products and the packages if you can meet our MOQ.

Q: How to guarantee the quality of your products?

A: 1) stict detection during production. 2) Strict completely inspecion on products before shipment and intact product

packaging ensured.

Q: lf my drawings are safe?

A: Yes ,we can sign NDA.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

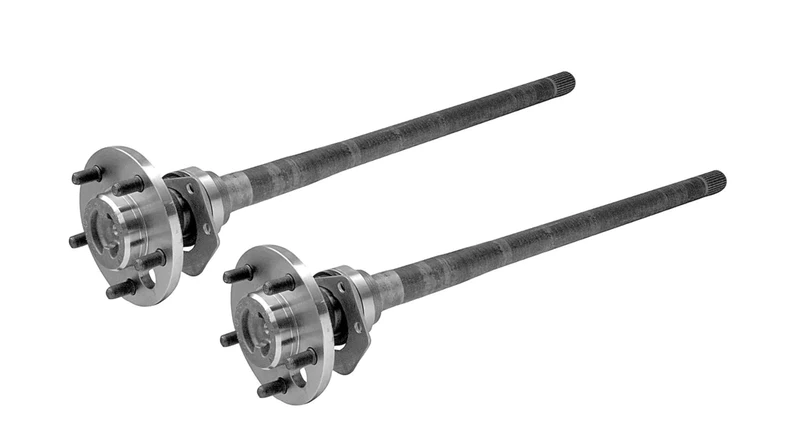

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | OEM/ODM/Customized |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | OEM/ODM/Customized |

| Customization: |

Available

| Customized Request |

|---|

Are there potential challenges or limitations to using specific axle shafts?

Using specific axle shafts in vehicles can come with challenges or limitations depending on various factors such as the design of the vehicle, the intended use, and the specific characteristics of the axle shafts. Here’s a detailed explanation of potential challenges or limitations associated with specific axle shafts:

- Compatibility: One challenge is ensuring compatibility between the axle shafts and the vehicle’s drivetrain configuration, suspension system, and overall design. Axle shafts must be designed to fit the specific vehicle model and its corresponding drivetrain layout. Using incompatible axle shafts can lead to improper fitment, compromised performance, or even mechanical failures.

- Strength and Durability: Depending on the vehicle’s weight, power output, and intended use, specific axle shafts may have limitations in terms of strength and durability. Axle shafts subjected to heavy loads, aggressive driving, or off-road conditions may require higher-strength materials or specialized designs to withstand the forces and torque applied to them. Using axle shafts that are not adequately designed for the vehicle’s demands can result in premature wear, bending, or breakage.

- Performance Trade-offs: Different types of axle shafts offer different performance trade-offs. For example, solid axle shafts may provide durability and simplicity but can result in a harsher ride quality and limited independent wheel movement. On the other hand, CV (constant velocity) axle shafts offer smoother power delivery and greater wheel articulation but may have limitations in terms of torque capacity and durability under extreme conditions. It’s important to consider the specific requirements and priorities of the vehicle’s performance and select axle shafts accordingly.

- Cost and Availability: Certain axle shafts, especially those designed for specialized applications or high-performance vehicles, may be more expensive or harder to source compared to standard axle shafts. Limited availability can pose challenges when it comes to replacement or upgrade options. Additionally, aftermarket axle shafts might not always meet the same quality standards as original equipment manufacturer (OEM) parts, which could impact their performance and reliability.

- Modifications and Customization: Modifying or customizing axle shafts can introduce additional challenges. Altering axle shafts to accommodate different drivetrain configurations, wheel sizes, or suspension setups may require specialized knowledge, engineering expertise, and fabrication skills. Improper modifications can negatively affect the vehicle’s stability, handling, and safety.

- Serviceability: Some specific axle shafts might have limited serviceability or require specialized tools or expertise for maintenance, repair, or replacement. This can impact the availability and cost of servicing the vehicle. It’s important to consider the long-term serviceability and support for specific axle shafts when selecting them for a vehicle.

It’s crucial to consult with knowledgeable professionals, such as automotive engineers or experienced mechanics, to ensure the appropriate selection and installation of axle shafts for a specific vehicle. They can provide valuable insights and guidance based on the vehicle’s requirements, intended use, and potential limitations associated with specific axle shafts.

In summary, potential challenges or limitations of using specific axle shafts include compatibility issues, limitations in strength and durability, performance trade-offs, cost and availability considerations, challenges related to modifications or customization, and serviceability concerns. A careful assessment of these factors is essential to ensure the optimal performance, safety, and reliability of the vehicle.

Can you describe the maintenance and repair considerations for axle shafts?

Maintenance and repair of axle shafts are essential to ensure the proper functioning and longevity of a vehicle’s drivetrain. Regular maintenance and timely repairs can help prevent costly damages and maintain optimal performance. Here’s a detailed explanation of the maintenance and repair considerations for axle shafts:

Maintenance Considerations:

To keep the axle shafts in good condition, the following maintenance practices are recommended:

- Inspections: Regularly inspect the axle shafts for signs of damage, such as cracks, bends, or excessive wear. Inspect the CV joints, bearings, seals, and retaining devices for leaks, deterioration, or looseness. Pay attention to any unusual noises, vibrations, or fluid leaks that may indicate potential issues.

- Lubrication: Ensure proper lubrication of the axle shafts, CV joints, and bearings as recommended by the vehicle manufacturer. Lubrication helps reduce friction, prevent excessive wear, and extend the lifespan of the components. Check the lubricant levels and quality during routine maintenance and top up or replace the lubricant as needed.

- Seal Protection: Inspect the seals around the axle shafts for damage or leaks. Damaged seals can allow contaminants, such as dirt, moisture, and debris, to enter the axle assembly, leading to premature wear and potential failure of the components. Replace damaged seals promptly to maintain proper protection.

- Boot Inspection: If the axle shafts have constant velocity (CV) joints, inspect the protective boots regularly. The boots cover the CV joints and keep them protected and lubricated. Look for any signs of cracks, tears, or leaking grease. Damaged boots should be replaced promptly to prevent dirt and moisture from entering the CV joints.

- Wheel Bearing Maintenance: If the axle shafts incorporate wheel bearings, follow the manufacturer’s recommendations for bearing maintenance. This may include periodic inspection, cleaning, re-greasing, or replacement of the wheel bearings to ensure smooth rotation and prevent excessive wear.

Repair Considerations:

If axle shaft issues are identified through inspections or during routine maintenance, the following repair considerations should be taken into account:

- Evaluation and Diagnosis: When encountering axle shaft problems, it’s important to accurately diagnose the issue before proceeding with repairs. This may involve a visual inspection, listening for abnormal noises, performing tests, or seeking professional assistance to identify the specific cause of the problem.

- Component Replacement: Depending on the nature and severity of the issue, repair options may vary. In some cases, replacing individual components such as CV joints, bearings, or seals may be sufficient. However, if the axle shaft itself is damaged or worn beyond repair, it may be necessary to replace the entire axle shaft assembly.

- Professional Expertise: Axle shaft repairs can be complex and require specialized knowledge and tools. It is often recommended to seek the assistance of a qualified mechanic or technician who has experience working with axle shafts. They can provide proper diagnosis, perform repairs accurately, and ensure the correct installation of components.

- Quality Parts: When replacing axle shaft components or the entire assembly, it is crucial to use high-quality parts that meet or exceed the manufacturer’s specifications. Using genuine or reputable aftermarket parts can help ensure proper fit, performance, and durability.

- Alignment and Calibration: After axle shaft repairs or replacements, it may be necessary to perform wheel alignment and calibration procedures to ensure proper suspension geometry, wheel balance, and drivetrain synchronization. This helps maintain vehicle stability, tire wear, and overall performance.

By following these maintenance practices and considering the appropriate repair steps, owners can help keep axle shafts in optimal condition, minimize the risk of failure, and ensure the reliable operation of the vehicle’s drivetrain.

Are there different axle shaft designs for rear-wheel drive and front-wheel drive vehicles?

Yes, rear-wheel drive (RWD) and front-wheel drive (FWD) vehicles typically employ different axle shaft designs to accommodate their respective drivetrain configurations. The axle shafts in RWD and FWD vehicles differ in their construction, orientation, and connection to the wheels. Here’s a detailed explanation of the axle shaft designs used in RWD and FWD vehicles:

Rear-Wheel Drive (RWD) Vehicles:

In RWD vehicles, the engine’s power is transmitted to the rear wheels through the drivetrain components. The axle shaft design in RWD vehicles is commonly referred to as a solid axle or full-floating axle. Here are the key characteristics of RWD axle shafts:

- Rigid Shaft: RWD axle shafts are typically solid and rigid, connecting the differential directly to each rear wheel. They are designed to handle high torque loads and provide robustness, making them suitable for heavy-duty applications.

- Single Connection: Each rear wheel has its own dedicated axle shaft, which connects directly to the wheel hub. The axle shaft transfers power to the wheel, enabling it to rotate.

- Support and Power Transfer: RWD axle shafts support the weight of the vehicle and transmit torque from the differential to the wheels. They facilitate smooth power delivery and enable the rear wheels to propel the vehicle forward or backward.

- Less Articulation: Since RWD vehicles typically have a solid rear axle, the axle shafts have limited articulation compared to FWD vehicles. This design simplifies the construction but may result in reduced suspension flexibility and a harsher ride quality.

Front-Wheel Drive (FWD) Vehicles:

In FWD vehicles, the engine’s power is transmitted to the front wheels through the drivetrain components. FWD axle shafts are commonly known as half shafts or CV axles (constant velocity axles). Here are the main characteristics of FWD axle shafts:

- Compact and Lightweight: FWD axle shafts are typically lighter and more compact than RWD axle shafts. They are designed to accommodate the space limitations in the front-wheel-drive layout.

- Constant Velocity (CV) Joints: FWD axle shafts incorporate constant velocity (CV) joints, which allow for flexibility and rotation at various angles. CV joints compensate for the changing length and angle of the axle shafts during suspension movement and steering.

- Transverse Orientation: FWD axle shafts are positioned transversely across the vehicle, connecting the differential or transaxle to the front wheels. This orientation allows for efficient power transfer and space utilization in FWD vehicles.

- Support and Power Transfer: FWD axle shafts support the weight of the vehicle and transmit torque from the differential or transaxle to the front wheels. They enable the front wheels to rotate and provide the driving force for vehicle movement.

- Increased Articulation: FWD axle shafts have greater articulation capabilities due to the need to accommodate suspension movement and steering angles. The CV joints allow the axle shafts to flex and rotate, ensuring smooth power delivery even when the wheels are turned or the suspension is compressed.

These axle shaft designs in RWD and FWD vehicles are tailored to the specific requirements and configurations of each drivetrain layout. They optimize power transmission, support the wheels, and ensure efficient operation based on the unique characteristics of rear-wheel drive and front-wheel drive systems.

editor by CX 2024-04-09

China Professional China Factory Custom Grinding Hard Chrome Engine Metal Stainless Steel Spindle Linear Shaft Transmission Motor Axle Shaft axle barbell

Product Description

Product Description

|

Company Profile

HangZhou Xihu (West Lake) Dis. Machinery Manufacture Co., Ltd., located in HangZhou, “China’s ancient copper capital”, is a “national high-tech enterprise”. At the beginning of its establishment, the company adhering to the “to provide clients with high quality products, to provide timely service” concept, adhere to the “everything for the customer, make customer excellent supplier” for the mission.

Certifications

Q: Where is your company located ?

A: HangZhou ZheJiang .

Q: How could l get a sample?

A: Before we received the first order, please afford the sample cost and express fee. we will return the sample cost back

to you within your first order.

Q: Sample time?

A: Existing items: within 20-60 days.

Q: Whether you could make our brand on your products?

A: Yes. We can print your Logo on both the products and the packages if you can meet our MOQ.

Q: How to guarantee the quality of your products?

A: 1) stict detection during production. 2) Strict completely inspecion on products before shipment and intact product

packaging ensured.

Q: lf my drawings are safe?

A: Yes ,we can sign NDA.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

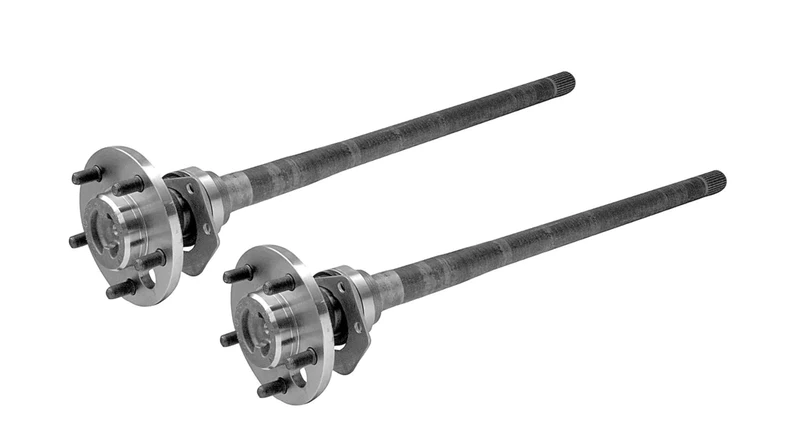

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | OEM/ODM/Customized |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | OEM/ODM/Customized |

| Customization: |

Available

| Customized Request |

|---|

What innovations or advancements have been made in axle shaft technology?

Axle shaft technology has witnessed several innovations and advancements over the years, aimed at improving performance, durability, and efficiency. These advancements have been driven by the need to meet evolving vehicle requirements, enhance safety, and reduce environmental impact. Here’s a detailed explanation of some notable innovations in axle shaft technology:

- High-Strength Materials: The development and utilization of high-strength materials have significantly improved the strength and durability of axle shafts. Advanced steel alloys, such as alloy steels, have been engineered to provide superior strength while reducing weight. This allows for increased load-bearing capacity, improved resistance to bending and torsional forces, and enhanced overall performance.

- Composite Axle Shafts: Composite materials, including carbon fiber reinforced polymers (CFRP), have been introduced in axle shaft technology. These materials offer exceptional strength-to-weight ratios, allowing for significant weight reduction while maintaining or even enhancing strength characteristics. Composite axle shafts can contribute to improved fuel efficiency, handling, and performance.

- Advanced Manufacturing Techniques: Innovations in manufacturing techniques have played a vital role in axle shaft technology. Precision machining, forging, and advanced casting methods allow for the production of axle shafts with complex geometries, enhanced surface finishes, and optimized material distribution. These techniques enable the creation of stronger and more efficient axle shafts that can withstand higher loads and provide improved performance.

- Improved Lubrication Systems: Lubrication systems have undergone advancements to ensure optimal performance and longevity of axle shafts. The development of advanced lubricants and improved sealing technologies helps maintain proper lubrication, reducing friction and wear between moving parts. Enhanced lubrication systems contribute to increased efficiency, reduced maintenance requirements, and extended lifespan of axle shafts.

- Electronic Differential Systems: Electronic differential systems, such as electronic limited-slip differentials (eLSD) and torque vectoring systems, have revolutionized axle shaft technology. These systems use sensors, actuators, and electronic control units to distribute torque between the wheels more effectively. By actively managing power delivery, electronic differential systems improve traction, stability, and handling, particularly in challenging driving conditions.

- Integration with Vehicle Dynamics Systems: Axle shaft technology has evolved to integrate with advanced vehicle dynamics control systems. This integration enables seamless coordination between the axle shafts, anti-lock braking systems (ABS), stability control systems, and other safety features. By working in tandem, these systems optimize traction, stability, and overall vehicle performance, enhancing safety and driver confidence.

These innovations and advancements in axle shaft technology have led to significant improvements in performance, strength, efficiency, and safety. High-strength materials, composite axle shafts, advanced manufacturing techniques, improved lubrication systems, electronic differential systems, and integration with vehicle dynamics systems have all contributed to enhanced functionality and durability of axle shafts.

In summary, axle shaft technology has seen notable advancements in recent years. These include the use of high-strength materials, the introduction of composite axle shafts, advancements in manufacturing techniques, improved lubrication systems, the implementation of electronic differential systems, and integration with vehicle dynamics systems. These innovations aim to enhance performance, durability, efficiency, and safety in axle shaft applications, meeting the evolving needs of modern vehicles.

What are the advantages of using high-performance or heavy-duty axle shafts?

Using high-performance or heavy-duty axle shafts can offer several advantages in terms of strength, durability, and performance. These specialized axle shafts are designed to handle increased torque loads, provide improved power delivery, and withstand the demands of challenging applications. Here’s a detailed explanation of the advantages of using high-performance or heavy-duty axle shafts:

- Increased Strength: High-performance or heavy-duty axle shafts are typically constructed from stronger materials, such as chromoly steel or alloy steel. These materials offer higher tensile and yield strength compared to standard axle shafts. The increased strength allows the shafts to handle higher torque loads without deformation or failure, providing enhanced reliability and durability.

- Improved Power Delivery: High-performance axle shafts are designed to provide more efficient power delivery from the drivetrain to the wheels. The enhanced strength and rigidity of these shafts minimize power loss due to torsional flex, ensuring that a greater percentage of the torque generated by the engine reaches the wheels. This results in improved acceleration, better throttle response, and enhanced overall performance.

- Enhanced Torsional Rigidity: Heavy-duty axle shafts are often engineered with increased torsional rigidity. This means they have reduced torsional flex or twisting under load. The improved torsional rigidity helps maintain consistent power transfer to the wheels, especially during high-torque situations or aggressive driving maneuvers. It contributes to better traction and stability, particularly in performance-oriented or off-road applications.

- Increased Durability: High-performance or heavy-duty axle shafts are designed to withstand the demands of challenging applications. They are engineered to handle increased loads, higher rotational speeds, and more extreme operating conditions. By providing greater durability, these axle shafts can withstand off-road obstacles, heavy payloads, or aggressive driving without premature wear or failure.

- Improved Off-Road Capability: High-performance or heavy-duty axle shafts are particularly beneficial in off-road applications. They can handle the additional stresses and forces encountered during off-road driving, such as uneven terrain, rock crawling, or high-speed desert runs. With increased strength and durability, these axle shafts reduce the risk of breakage, allowing off-road enthusiasts to explore challenging terrains with more confidence.

- Support for Vehicle Modifications: High-performance or heavy-duty axle shafts are often used in vehicles with significant modifications, such as increased engine power, larger tires, or suspension upgrades. These axle shafts can accommodate the additional torque loads and provide the necessary strength and reliability to support the modified drivetrain and suspension components.

It’s important to note that the advantages of high-performance or heavy-duty axle shafts are most noticeable in applications where the vehicle is subjected to increased torque loads, extreme conditions, or performance-oriented driving. In everyday driving scenarios with standard vehicles, the benefits may be less pronounced.

When considering high-performance or heavy-duty axle shafts, it’s crucial to ensure compatibility with other drivetrain components, such as the differential, wheel hubs, and braking system. Additionally, professional installation by experienced technicians is recommended to ensure proper fitment and compatibility.

Overall, high-performance or heavy-duty axle shafts offer increased strength, improved power delivery, enhanced durability, and better performance characteristics, making them a valuable upgrade for specific applications where increased performance, reliability, and off-road capability are desired.

How does an axle shaft transfer power from the differential to the wheels?

An axle shaft serves as a crucial component in transferring power from the differential to the wheels of a vehicle. It plays a vital role in transmitting torque and enabling the wheels to rotate. Here is an explanation of how an axle shaft transfers power:

1. Differential Connection:

The axle shaft is connected to the differential, which is a device located between the transmission or transaxle and the wheels. The differential receives rotational power from the engine through the transmission or transaxle and splits it between the two axle shafts. The axle shafts are connected to the differential’s side gears or output shafts, ensuring a solid mechanical connection.

2. Torque Distribution:

As the engine generates torque, it is transferred through the drivetrain to the differential. The differential acts as a torque distributor, allocating the rotational force between the two axle shafts. In a rear-wheel-drive vehicle, the differential splits the torque equally between the two rear axle shafts. In a front-wheel-drive vehicle, the differential or transaxle distributes the torque to the two front axle shafts.

3. Power Transmission:

Once the torque is divided by the differential, each axle shaft receives a portion of the power. The axle shafts transmit this power to the respective wheels, enabling them to rotate and propel the vehicle forward or backward. The rotational force from the axle shafts is transferred to the wheel hubs or constant velocity (CV) joints, which are connected to the wheels. The wheel hubs or CV joints allow the rotational motion to be transferred to the wheels while accommodating suspension movement and steering angles.

4. Wheel Rotation:

As the axle shafts rotate, the power they transmit causes the wheels to rotate at the same speed. This rotation generates the necessary torque at the wheel contact patches, allowing the vehicle to move. The rotational motion of the wheels is essential for traction, acceleration, deceleration, and maneuverability.

5. Suspension Flexibility:

An axle shaft must also allow for suspension flex and wheel articulation. As the suspension moves up and down, the axle shafts accommodate the changes in axle length and angle. This flexibility is especially important in off-road vehicles and those equipped with independent suspension systems. In such cases, the axle shafts are designed with features like constant velocity (CV) joints or universal joints to allow for smooth power transfer even when the wheels are at different angles or positions due to suspension movement.

Overall, an axle shaft transfers power from the differential to the wheels by connecting to the differential and transmitting torque to the wheels. This power transfer enables the wheels to rotate and provides the driving force necessary for vehicle movement.

editor by CX 2024-03-14

China manufacturer Factory Custom Precision Carbon Cue Shaft Worm Main Spindle Servo DC Motor Shaft Drive Axle Turning Shaft with high quality

Product Description

Product Description

Warranty

1 Year

Applicable Industries

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

Weight (KG)

1

Showroom Location

Viet Nam

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

Ordinary Product

Warranty of core components

1 Year

Core Components

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Material

steel

Place of Origin

ZheJiang , China

Condition

New

Structure

Shaft

Coatings

Customized

Torque Capacity

Customized

Model Number

Customized

Brand Name

NON

Description

Shaft

Machining equipment

CNC mill,lathe and grind machine

Material

stainless steel, aluminium, carbon

Surface

Grinding and polishing

Shape

Customized

Sampling time

10days

Production time

20days

Packing

Protective packing

Tolerance

±0.001

OEM

Welcome

Production Process

Company Profile

HangZhou HUANENGDA SPRING CO.,LTD

HangZhou HuaNengDa Spring Co., Ltd. is located in Tong ‘an District, HangZhou City, ZheJiang Province, China. It is a hardware factory specializing in R&D design, manufacture and sales of precision components. The company introduces domestic and foreign advanced equipment and production technology, adopts CNC high-precision computer machine, compression spring machine, CNC five-axis linkage machining center, CNC turning and milling compound, 300 tons of punch and other mechanical equipment,and employs senior engineers with more than 10 years of work experience to debug mechanical equipment and customize production.

With the business philosophy of honesty, pragmatism and excellence, HuaNengDa Spring Company is dedicated to serving customers at home and abroad. We hope that the products of HuaNengDa will help your business to be more brilliant, let us build a bright future in the high-tech era!

The testimony is pragmatic and the attitude of the people. Quality service is the pursuit of the people!

Factory Workshop

Production Procedur

Quality Inspection

Packing And Shipping

Our Service

FAQ

1.Small order quantity is workable

From the initial sample design of the spring to the mass production of the springs, we can quickly reach your manufacturing goals and immediately provide the best products because we have an excellent production management system and expertly trained technical personnel.

2.Committed to high quality production

To keep HuaNengDa Springs at the forefront of the industry, we have implemented a stringent internal quality control system and regularly import the latest manufacturing equipment and instruments. Through our precise manufacturing technology and expert mold making process, we provide our customers with the best products and service.

3.Efficiency in manufacturing

Our company’s machinery and equipment are controlled by CNC computers. In order to respond to international needs and standards, we continuously update and upgrade our equipment every year. Our machines effectively increase production capacity and save on manufacturing costs. The manufacturing department is the most important core of the whole company and by treating it with utmost importance, we reap great benefits in manufacturing efficiency.

4.Excellent customization services

HuaNengDa’s R&D team designs and completes customized products according to the needs of customers. From the selection of materials to the function of the products, we can design and develop products to suite different customers’ requirements. We are constantly involving ourselves in all aspects of the industry because only by having a complete view and analysis of the industry, can there be innovative breakthroughs.

Payment term

*T/T : 30% pre T/T, 70% before delivery.

*Trade Assurance

Service

*Delivery on time.

*Shipped by a convenient and cost-effective way.

*Good after-selling, 24 hours service for you.

Packing

*A: Poly bag, Plstic tray ,small box, carton.

*B: According to customers’ requirements.

Delivery

*Sample: 7-10 days after deposit received.

*Batch goods: 12-15 days after samples approved. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Certification: | ISO9001 |

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Material: | Steel,Stainless Steel,Iron |

| Application: | Metal Processing Machinery Parts |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you explain the impact of axle shaft materials on weight and strength?

The choice of material for axle shafts has a significant impact on both weight and strength characteristics. Different materials offer varying levels of strength-to-weight ratios, which can influence the overall performance and durability of the axle shafts. Here’s an explanation of how axle shaft materials affect weight and strength:

- Steel: Steel is a commonly used material for axle shafts due to its high strength and durability. Steel axle shafts are known for their excellent load-bearing capacity and resistance to bending and torsional forces. However, steel is relatively heavy compared to other materials, which can contribute to increased overall weight of the vehicle. The weight of steel axle shafts can affect the vehicle’s fuel efficiency and handling characteristics.

- Alloy Steel: Alloy steel is a type of steel that has been mixed with other elements to enhance specific properties. By adding elements such as chromium, molybdenum, or nickel, alloy steel can achieve improved strength and hardness compared to traditional steel. This allows for the production of lighter and stronger axle shafts compared to conventional steel, providing a balance between weight reduction and structural integrity.

- Aluminum: Aluminum is a lightweight material known for its excellent strength-to-weight ratio. When used in axle shafts, aluminum can significantly reduce the weight of the component, which can lead to benefits such as improved fuel efficiency and handling. However, aluminum axle shafts may not be as strong as steel shafts and can be more susceptible to bending or deformation under high loads or extreme conditions.

- Composite Materials: Composite materials, such as carbon fiber reinforced polymers (CFRP), are increasingly being explored for axle shaft applications. CFRP composites offer high strength and light weight, making them attractive for weight reduction purposes. These materials can provide comparable or even superior strength compared to steel while significantly reducing the overall weight of the axle shafts. However, composite materials often come with higher production costs and may require specialized manufacturing techniques.

Overall, the choice of axle shaft material involves a trade-off between weight reduction and strength requirements. Steel offers excellent strength but comes with higher weight, while materials like aluminum and composites offer weight savings at the expense of some strength characteristics. The selection of the most suitable material depends on various factors, including the vehicle’s intended use, load requirements, cost considerations, and desired performance attributes.

In summary, the impact of axle shaft materials on weight and strength is significant. Steel provides high strength but adds weight, alloy steel offers a balance between strength and weight, aluminum reduces weight but may sacrifice some strength, and composite materials provide strength and weight advantages but at potentially higher costs. Manufacturers consider these factors when selecting axle shaft materials to achieve the desired balance of weight reduction, strength, and overall performance in vehicles.

Can axle shafts be customized or upgraded for specific applications?

Axle shafts can indeed be customized or upgraded to meet specific application requirements. Depending on the intended use, performance goals, and vehicle modifications, customization or upgrading of axle shafts can provide several benefits. Here’s a detailed explanation of customizing and upgrading axle shafts for specific applications:

Customization:

Customization of axle shafts involves tailoring their design, materials, and specifications to suit specific application needs. Some common examples of axle shaft customization include:

- Material Selection: Axle shafts can be customized by choosing different materials based on the desired strength, weight, and durability. For high-performance applications, materials such as chromoly steel or alloy steel may be selected to enhance strength and withstand increased torque loads.

- Length and Splines: The length and spline count of axle shafts can be customized to accommodate vehicle modifications or specific drivetrain setups. This ensures proper fitment and engagement with the differential or transaxle and the wheel hubs.

- Upgraded CV Joints: In applications that require increased articulation or heavy-duty off-road use, the constant velocity (CV) joints on the axle shafts can be upgraded to more robust and durable versions. Upgraded CV joints can better withstand extreme angles and off-road stresses.

- Performance Enhancements: Custom axle shafts can be designed to handle higher torque loads or provide improved performance characteristics. This can involve optimizing the shaft diameter, wall thickness, or other design parameters to enhance strength, reduce weight, or increase torsional rigidity.

Upgrades:

In addition to customization, upgrading axle shafts with aftermarket components or specialized kits is another option for specific applications. Upgrades can provide enhanced performance, durability, or specialized features. Some common axle shaft upgrades include:

- Performance Axle Shafts: Aftermarket performance axle shafts are available for vehicles used in high-performance applications, such as racing or off-roading. These shafts are designed to handle increased torque loads, provide better strength, and improve power delivery efficiency.

- Locking Differentials: Upgrading to a locking differential system can enhance off-road performance by ensuring power is evenly distributed to both wheels, improving traction in challenging terrain. Upgraded axle shafts may be necessary to accommodate the locking differential mechanism.

- Upgraded Bearings and Seals: Upgrading the bearings and seals on axle shafts can improve durability and longevity. This is particularly beneficial in heavy-duty applications or environments with high levels of dust, moisture, or contaminants.

- Axle Shaft Reinforcement: For vehicles subjected to extreme loads or heavy modifications, axle shaft reinforcement kits can be installed. These kits typically include additional bracing or gussets to strengthen the axle housing and prevent bending or failure of the axle shafts.

It’s important to note that axle shaft customization or upgrading may require careful consideration of other drivetrain components, such as differential, wheel hubs, and suspension geometry. Additionally, such modifications should be performed by qualified professionals with expertise in axle shafts and drivetrain systems to ensure proper installation and compatibility.

By customizing or upgrading axle shafts to specific applications, vehicle owners can optimize performance, durability, and reliability, tailored to their unique needs and requirements.

Can you explain the different types of axle shafts used in automobiles?

Automobiles utilize different types of axle shafts depending on the vehicle’s drivetrain configuration, suspension design, and intended use. Here are some of the commonly used axle shaft types:

1. Solid Axle Shaft:

A solid axle shaft, also known as a full-floating axle, is a single, rigid shaft that connects the differential to the wheels. It is commonly used in rear-wheel-drive vehicles, trucks, and off-road vehicles. Solid axle shafts provide robustness and strength, making them suitable for heavy-duty applications. They are capable of handling high torque loads and are relatively simple in design. However, solid axle shafts can contribute to a harsher ride and increased unsprung weight compared to other axle types.

2. Split Axle Shaft:

A split axle shaft, also referred to as a semi-floating axle, consists of two separate shafts that connect the differential to each wheel independently. Split axle shafts are commonly used in light-duty passenger vehicles and some rear-wheel-drive trucks. Each shaft supports the weight of its corresponding wheel and transmits torque. Split axle shafts offer a balance between strength and weight savings compared to solid axle shafts. However, they are generally not as robust as full-floating axles and may have lower load-carrying capacity.

3. Half Shaft:

A half shaft, also known as a drive shaft or CV axle, is commonly used in front-wheel-drive and all-wheel-drive vehicles. It connects the differential or transaxle to the front wheels, allowing power transmission and wheel rotation. Half shafts are typically equipped with constant velocity (CV) joints, which accommodate the articulation and angle changes during suspension movement and steering. CV joints enable smooth power transfer and minimize vibrations. Half shafts are usually lighter and more compact than solid or split axle shafts and are designed to handle the demands of front-wheel-drive systems.

4. Torque Tube Axle:

A torque tube axle is an older design that was used in some early automobiles. It consists of a single tube that encases the driveshaft and connects the differential to the wheels. The torque tube axle provides power transmission and support for the wheels but lacks independent suspension. This design has largely been phased out in modern vehicles, as it limits suspension flexibility and can contribute to a harsher ride quality.

5. Independent Rear Suspension Axle Shafts:

In vehicles with independent rear suspension (IRS), each wheel typically has its own axle shaft. These axle shafts connect the differential to the individual wheels and allow independent movement and suspension articulation. Independent rear suspension axle shafts are commonly found in modern passenger cars and some high-performance vehicles. They provide improved handling, ride comfort, and traction compared to solid axle shafts. The design and construction of these axle shafts may vary depending on the specific IRS system implemented in the vehicle.

It’s important to note that the specific axle shaft types used in automobiles can vary depending on the vehicle manufacturer, model, and drivetrain configuration. Additionally, advancements in technology and the increasing popularity of electric vehicles may introduce new axle shaft designs and materials in the future.

In summary, the different types of axle shafts used in automobiles include solid axle shafts, split axle shafts, half shafts, torque tube axles (less common in modern vehicles), and independent rear suspension axle shafts. Each type has its own advantages and is tailored to specific vehicle applications and requirements.

editor by CX 2024-02-23

China Good quality China Manufacturer Custom Lighting Turning Precision Stainless Steel Axle Stepped Drive Shaft with Mechanical Parts for Robot Vacuum and Motor dexter axle

Product Description

Company Profile

—–ABOUT US—–

Focuses on the research, development, production, sales and service of fasteners, precision hardware parts and various metal products.

HangZhou Bozuan Jinggong Technology Co., Ltd. was established on March 1, 2016. It is located in Xihu (West Lake) Dis.ang District, HangZhou City, ZheJiang Province. It covers an area of 5600 square meters and focuses on the research, development, production, sales and service of fasteners, precision hardware parts and various metal products. The processed products are mainly cold heading, forging, precision turning, milling, assembly, stamping, supplemented by extrusion, upsetting and casting. In addition, we also have rich experience in anodizing, electroplating and heat treatment.

Product Parameters

| No. | Item | Specifications |

| 1 | Materials | Carbon steel: 12L15, 45#, 42CrMo; Stainless steel: 303, 304, 316, 420, 630; Aluminum alloy: 6061, 6063, 5052, 7075; Copper alloy: brass H58-H63, phosphor bronze, beryllium copper; Pure copper: T0 oxygen-free copper, T2 red copper; Plastics: nylon, bakelite, POM, PEEK; |

| 2 | Diameter | Ø0.3-Ø50 |

| 3 | Diameter tolerance | 0.005mm |

| 4 | Hardness: | HRC/HV |

| 5 | Length | 0.5mm-500mm |

| 6 | Heat treatment | Oil Quenching High frequency quenching Carburization Vacuum Heat treatment Mesh belt CZPT heat treatment |

| 7 | Surface treatment | Electrolytic plating (barrel plating, rack plating); Electroless plating (nickel plating); Ordinary sandblasting and anodizing (black, silver, gray, gold, red) Plastic spraying, spraying metal paint, etc.; |

Work Shop

Certifications

Research & Development

Development intervention

Development ability

Cost accounting

Quality control

Production feasibility assessment

Project landing

Assembly service

Complex project decomposition & optimization capabilities

Quick sample

Optimization of the mold plan for mass products

Product Category

Precision turning parts

Precision machining parts

Special requirements appearance parts

Presentative Brand

Why Choose Us?

Create value for customers

Support + Service + Made in China + Technological Innovation = Solution

★ Project management, solutions

★ Quickly designing and sampling

★ New product development, technological breakthrough

★ Component and machine assembly service

Engineering capabilities

★Development intervention

★Development ability

Cost accounting

Quality control

Production feasibility assessment

Project landing

Assembly service

★Complex project decomposition & optimization capabilities

★Quick sample

★Optimization of the mold plan for mass products /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Stepped Shaft |

| Customization: |

Available

| Customized Request |

|---|

How does proper maintenance extend the lifespan of axle shafts and drivetrains?

Proper maintenance plays a crucial role in extending the lifespan of axle shafts and drivetrains in vehicles. By following recommended maintenance practices, owners can prevent premature wear, identify potential issues early, and ensure optimal performance. Here’s a detailed explanation of how proper maintenance extends the lifespan of axle shafts and drivetrains:

- Lubrication: Regular lubrication is essential for axle shafts and drivetrain components. Adequate lubrication reduces friction between moving parts, minimizing wear and heat generation. It helps prevent metal-to-metal contact, which can lead to damage and premature failure. Proper lubrication ensures smooth operation and protects against corrosion, promoting the longevity of axle shafts and drivetrain components.

- Fluid Inspection and Replacement: Regular inspection and replacement of fluids, such as gear oil and transmission fluid, are essential for maintaining the health of axle shafts and drivetrains. Over time, fluids can become contaminated, lose their lubricating properties, or develop excessive wear particles. By regularly inspecting and replacing fluids according to the manufacturer’s recommendations, owners can ensure optimal lubrication and cooling, reducing the risk of component damage and extending the lifespan of axle shafts and drivetrains.

- Seal and Boot Maintenance: Axle shafts are equipped with seals and boots that protect them from contamination and retain lubricants. Proper maintenance involves inspecting and replacing damaged or worn seals and boots. Cracked or torn boots can allow dirt, moisture, and debris to enter, leading to accelerated wear and potential damage to the axle shafts and other drivetrain components. Regular maintenance of seals and boots helps maintain a protective barrier, preserving the integrity and longevity of the axle shafts and drivetrains.