Product Description

Product Description

Product Parameters

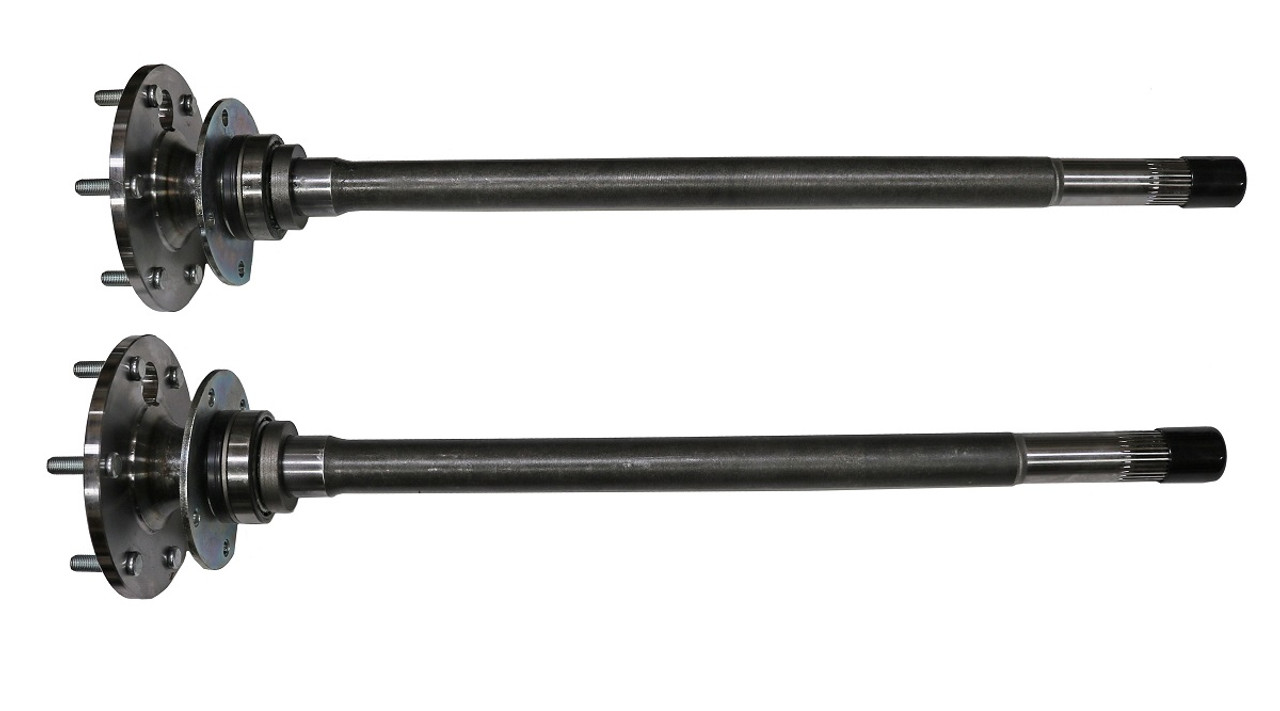

| Item | Spur Gear Axle Shaft |

| Material | 4140,4340,40Cr,42Crmo,42Crmo4,20Cr,20CrMnti, 20Crmo,35Crmo |

| OEM NO | Customize |

| Certification | ISO/TS16949 |

| Test Requirement | Magnetic Powder Test, Hardness Test, Dimension Test |

| Color | Paint , Natural Finish ,Machining All Around |

| Material | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Steel: Carbon Steel,Middle Steel,Steel Alloy,etc. | |

| Stainess Steel: 303/304/316,etc. | |

| Copper/Brass/Bronze/Red Copper,etc. | |

| Plastic:ABS,PP,PC,Nylon,Delrin(POM),Bakelite,etc. | |

| Size | According to Customer’s drawing or samples |

| Process | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Cutting,etc. |

| Tolerance | ≥+/-0.03mm |

| Surface Treatment | (Sandblast)&(Hard)&(Color)Anodizing,(Chrome,Nickel,Zinc…)Plating,Painting,Powder Coating,Polishing,Blackened,Hardened,Lasering,Engraving,etc. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Available |

| Packing | Spline protect cover ,Wood box ,Waterproof membrane; Or per customers’ requirements. |

Our Advantages

Why Choose US ???

1. Equipment :

Our company boasts all necessary production equipment,

including Hydraulic press machines, Japanese CNC lathe (TAKISAWA), Korean gear hobbing machine (I SNT), gear shaping machine, machining center, CNC grinder, heat treatment line etc.

2. Processing precision:

We are a professional gear & gear shafts manufacturer. Our gears are around 6-7 grade in mass production.

3. Company:

We have 90 employees, including 10 technical staffs. Covering an area of 20000 square meters.

4. Certification :

Oue company has passed ISO 14001 and TS16949

5.Sample service :

We provide free sample for confirmation and customer bears the freight charges

6.OEM service :

Having our own factory and professional technicians,we welcome OEM orders as well.We can design and produce the specific product you need according to your detail information

Cooperation Partner

Company Profile

Our Featured Products

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Axis Shape: | Straight Shaft |

| Appearance Shape: | Round |

| Rotation: | Cw |

| Yield: | 5, 000PCS / Month |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you explain the impact of axle shaft materials on weight and strength?

The choice of material for axle shafts has a significant impact on both weight and strength characteristics. Different materials offer varying levels of strength-to-weight ratios, which can influence the overall performance and durability of the axle shafts. Here’s an explanation of how axle shaft materials affect weight and strength:

- Steel: Steel is a commonly used material for axle shafts due to its high strength and durability. Steel axle shafts are known for their excellent load-bearing capacity and resistance to bending and torsional forces. However, steel is relatively heavy compared to other materials, which can contribute to increased overall weight of the vehicle. The weight of steel axle shafts can affect the vehicle’s fuel efficiency and handling characteristics.

- Alloy Steel: Alloy steel is a type of steel that has been mixed with other elements to enhance specific properties. By adding elements such as chromium, molybdenum, or nickel, alloy steel can achieve improved strength and hardness compared to traditional steel. This allows for the production of lighter and stronger axle shafts compared to conventional steel, providing a balance between weight reduction and structural integrity.

- Aluminum: Aluminum is a lightweight material known for its excellent strength-to-weight ratio. When used in axle shafts, aluminum can significantly reduce the weight of the component, which can lead to benefits such as improved fuel efficiency and handling. However, aluminum axle shafts may not be as strong as steel shafts and can be more susceptible to bending or deformation under high loads or extreme conditions.

- Composite Materials: Composite materials, such as carbon fiber reinforced polymers (CFRP), are increasingly being explored for axle shaft applications. CFRP composites offer high strength and light weight, making them attractive for weight reduction purposes. These materials can provide comparable or even superior strength compared to steel while significantly reducing the overall weight of the axle shafts. However, composite materials often come with higher production costs and may require specialized manufacturing techniques.

Overall, the choice of axle shaft material involves a trade-off between weight reduction and strength requirements. Steel offers excellent strength but comes with higher weight, while materials like aluminum and composites offer weight savings at the expense of some strength characteristics. The selection of the most suitable material depends on various factors, including the vehicle’s intended use, load requirements, cost considerations, and desired performance attributes.

In summary, the impact of axle shaft materials on weight and strength is significant. Steel provides high strength but adds weight, alloy steel offers a balance between strength and weight, aluminum reduces weight but may sacrifice some strength, and composite materials provide strength and weight advantages but at potentially higher costs. Manufacturers consider these factors when selecting axle shaft materials to achieve the desired balance of weight reduction, strength, and overall performance in vehicles.

What are the advantages of using high-performance or heavy-duty axle shafts?

Using high-performance or heavy-duty axle shafts can offer several advantages in terms of strength, durability, and performance. These specialized axle shafts are designed to handle increased torque loads, provide improved power delivery, and withstand the demands of challenging applications. Here’s a detailed explanation of the advantages of using high-performance or heavy-duty axle shafts:

- Increased Strength: High-performance or heavy-duty axle shafts are typically constructed from stronger materials, such as chromoly steel or alloy steel. These materials offer higher tensile and yield strength compared to standard axle shafts. The increased strength allows the shafts to handle higher torque loads without deformation or failure, providing enhanced reliability and durability.

- Improved Power Delivery: High-performance axle shafts are designed to provide more efficient power delivery from the drivetrain to the wheels. The enhanced strength and rigidity of these shafts minimize power loss due to torsional flex, ensuring that a greater percentage of the torque generated by the engine reaches the wheels. This results in improved acceleration, better throttle response, and enhanced overall performance.

- Enhanced Torsional Rigidity: Heavy-duty axle shafts are often engineered with increased torsional rigidity. This means they have reduced torsional flex or twisting under load. The improved torsional rigidity helps maintain consistent power transfer to the wheels, especially during high-torque situations or aggressive driving maneuvers. It contributes to better traction and stability, particularly in performance-oriented or off-road applications.

- Increased Durability: High-performance or heavy-duty axle shafts are designed to withstand the demands of challenging applications. They are engineered to handle increased loads, higher rotational speeds, and more extreme operating conditions. By providing greater durability, these axle shafts can withstand off-road obstacles, heavy payloads, or aggressive driving without premature wear or failure.

- Improved Off-Road Capability: High-performance or heavy-duty axle shafts are particularly beneficial in off-road applications. They can handle the additional stresses and forces encountered during off-road driving, such as uneven terrain, rock crawling, or high-speed desert runs. With increased strength and durability, these axle shafts reduce the risk of breakage, allowing off-road enthusiasts to explore challenging terrains with more confidence.

- Support for Vehicle Modifications: High-performance or heavy-duty axle shafts are often used in vehicles with significant modifications, such as increased engine power, larger tires, or suspension upgrades. These axle shafts can accommodate the additional torque loads and provide the necessary strength and reliability to support the modified drivetrain and suspension components.

It’s important to note that the advantages of high-performance or heavy-duty axle shafts are most noticeable in applications where the vehicle is subjected to increased torque loads, extreme conditions, or performance-oriented driving. In everyday driving scenarios with standard vehicles, the benefits may be less pronounced.

When considering high-performance or heavy-duty axle shafts, it’s crucial to ensure compatibility with other drivetrain components, such as the differential, wheel hubs, and braking system. Additionally, professional installation by experienced technicians is recommended to ensure proper fitment and compatibility.

Overall, high-performance or heavy-duty axle shafts offer increased strength, improved power delivery, enhanced durability, and better performance characteristics, making them a valuable upgrade for specific applications where increased performance, reliability, and off-road capability are desired.

Are there different axle shaft designs for rear-wheel drive and front-wheel drive vehicles?

Yes, rear-wheel drive (RWD) and front-wheel drive (FWD) vehicles typically employ different axle shaft designs to accommodate their respective drivetrain configurations. The axle shafts in RWD and FWD vehicles differ in their construction, orientation, and connection to the wheels. Here’s a detailed explanation of the axle shaft designs used in RWD and FWD vehicles:

Rear-Wheel Drive (RWD) Vehicles:

In RWD vehicles, the engine’s power is transmitted to the rear wheels through the drivetrain components. The axle shaft design in RWD vehicles is commonly referred to as a solid axle or full-floating axle. Here are the key characteristics of RWD axle shafts:

- Rigid Shaft: RWD axle shafts are typically solid and rigid, connecting the differential directly to each rear wheel. They are designed to handle high torque loads and provide robustness, making them suitable for heavy-duty applications.

- Single Connection: Each rear wheel has its own dedicated axle shaft, which connects directly to the wheel hub. The axle shaft transfers power to the wheel, enabling it to rotate.

- Support and Power Transfer: RWD axle shafts support the weight of the vehicle and transmit torque from the differential to the wheels. They facilitate smooth power delivery and enable the rear wheels to propel the vehicle forward or backward.

- Less Articulation: Since RWD vehicles typically have a solid rear axle, the axle shafts have limited articulation compared to FWD vehicles. This design simplifies the construction but may result in reduced suspension flexibility and a harsher ride quality.

Front-Wheel Drive (FWD) Vehicles:

In FWD vehicles, the engine’s power is transmitted to the front wheels through the drivetrain components. FWD axle shafts are commonly known as half shafts or CV axles (constant velocity axles). Here are the main characteristics of FWD axle shafts:

- Compact and Lightweight: FWD axle shafts are typically lighter and more compact than RWD axle shafts. They are designed to accommodate the space limitations in the front-wheel-drive layout.

- Constant Velocity (CV) Joints: FWD axle shafts incorporate constant velocity (CV) joints, which allow for flexibility and rotation at various angles. CV joints compensate for the changing length and angle of the axle shafts during suspension movement and steering.

- Transverse Orientation: FWD axle shafts are positioned transversely across the vehicle, connecting the differential or transaxle to the front wheels. This orientation allows for efficient power transfer and space utilization in FWD vehicles.

- Support and Power Transfer: FWD axle shafts support the weight of the vehicle and transmit torque from the differential or transaxle to the front wheels. They enable the front wheels to rotate and provide the driving force for vehicle movement.

- Increased Articulation: FWD axle shafts have greater articulation capabilities due to the need to accommodate suspension movement and steering angles. The CV joints allow the axle shafts to flex and rotate, ensuring smooth power delivery even when the wheels are turned or the suspension is compressed.

These axle shaft designs in RWD and FWD vehicles are tailored to the specific requirements and configurations of each drivetrain layout. They optimize power transmission, support the wheels, and ensure efficient operation based on the unique characteristics of rear-wheel drive and front-wheel drive systems.

editor by CX 2024-04-10