Product Description

Product Description

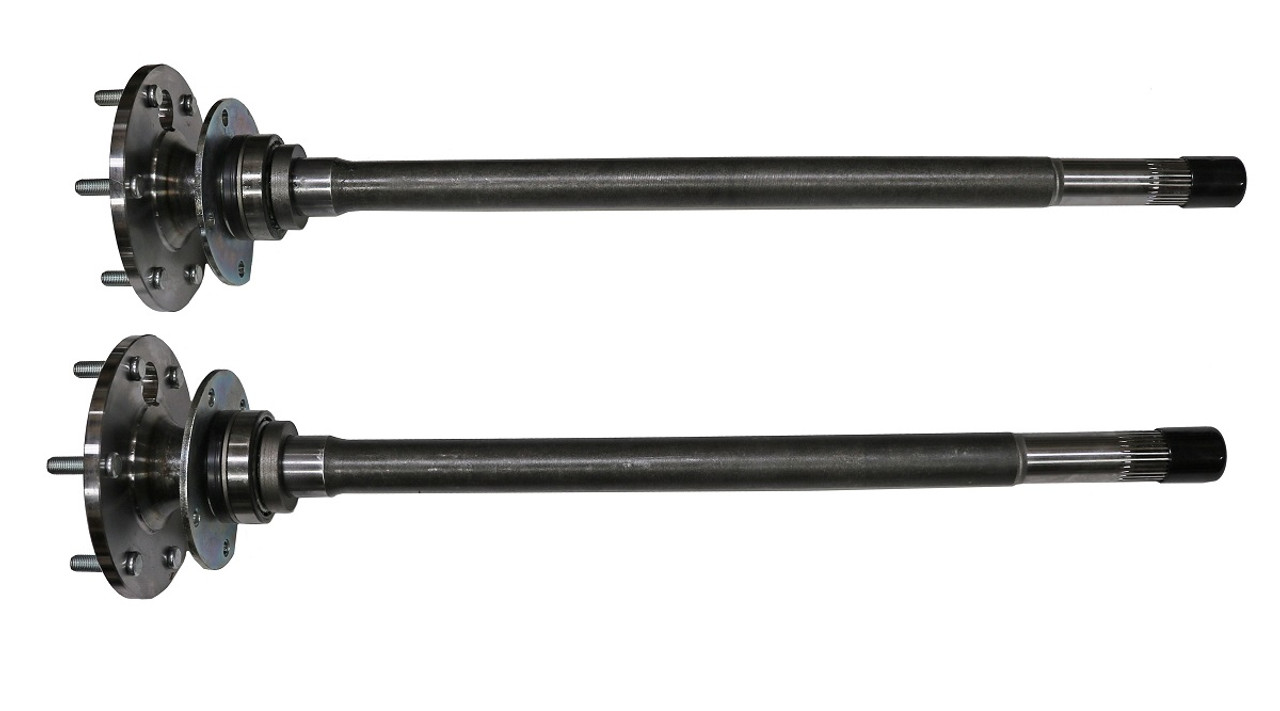

OUTPUT SHAFT COVER FOR BEIBEN FRONT AXLE DRIVE TRUCK,TRAILER,TRACTO

PART NUMBER:

86CL6395FO 86CL6089FO

70CL6081FOB 86CL6081F2 70CL6082FOB 3151

3303

014255713 A

0142508803 014255713

LRS0571 LRS00922 LRS819 LRS922 LRT0 0571 LRT668

Detailed Photos

WAREHOUSE CORNER:

We have factory to produce all kinds of clutch plate,clutch pressure,clutch disc for heavy duty truck,light truck,tractor..

We can also produce according to drawing or samples.

Packaging & Shipping

1. Packaging details: carton and wooden box packaging,woven bag,brown box, or

according to customer requirements.

2. Delivery Period: 7-30 working days after

receiving 30% deposit byTT

3. Port: HangZhou Port,China.

4. Transport: By sea, by

air,DHL,FEDEX,UPS,TNT,

FAQ

1.Q:About the payment term.

A: We can accept TT,LC,PAYPAL,WESTERNUION,and so on

2.Q:About the Quality and price

A: We supply good quality products to all our customers,give the competitive price.

3.Q:About the warranty period

A:At least half year, some parts are even longer.

4. Q:How to make order ?

A:Customer can contact us online,or send email with detail inquiry list,then we can reply soon

5.Q:About the discount

A:If the quantity large,we will give resonalbe discount.And for long time cooperation customer,we can give credit support

| After-sales Service: | Free Change for Quality Problem |

|---|---|

| Application: | Truck, Tractor, Special Truck, Trailer |

| Material: | Steel |

| Quality: | Original Quality;Good Quality |

| Package: | Export Standard Box or According to Customer Requi |

| Origina: | China |

What are the eco-friendly or sustainable aspects of axle shaft production?

Axle shaft production can incorporate several eco-friendly or sustainable practices that aim to minimize environmental impact and promote sustainability throughout the manufacturing process. Here’s a detailed explanation of the eco-friendly and sustainable aspects of axle shaft production:

- Material Selection: One of the primary considerations for eco-friendly axle shaft production is the selection of materials. Opting for sustainable materials, such as recycled steel or lightweight alloys, reduces the environmental footprint associated with raw material extraction and processing. Using recycled materials helps conserve natural resources and reduces energy consumption and greenhouse gas emissions compared to using virgin materials.

- Energy Efficiency: Promoting energy efficiency in axle shaft production is another eco-friendly aspect. Implementing energy-saving technologies, such as efficient manufacturing processes, optimized equipment, and smart controls, helps minimize energy consumption during production. Utilizing renewable energy sources, such as solar or wind power, further reduces greenhouse gas emissions and reliance on fossil fuels.

- Waste Reduction and Recycling: Axle shaft production can incorporate waste reduction and recycling practices to minimize the amount of waste generated and promote a circular economy. Implementing measures like effective waste management systems, recycling programs, and responsible disposal of hazardous materials ensures that waste is minimized, and valuable resources are recovered and reused whenever possible.

- Water Conservation: Sustainable axle shaft production also includes measures to conserve water resources. Implementing water-efficient technologies, recycling and treating water used in manufacturing processes, and implementing water management strategies help minimize water consumption and reduce the strain on freshwater resources.

- Emissions Reduction: Axle shaft production can focus on reducing emissions to minimize its environmental impact. Implementing emission control technologies, such as installing pollution control devices or adopting cleaner manufacturing processes, helps reduce air pollutants released during production. Additionally, monitoring and optimizing transportation logistics can help minimize carbon emissions associated with the transportation of raw materials and finished axle shafts.

- Life Cycle Assessment: Conducting a life cycle assessment (LCA) of axle shaft production allows for a comprehensive evaluation of the environmental impact at each stage, from raw material extraction to end-of-life disposal. LCA helps identify areas where improvements can be made, enabling manufacturers to make informed decisions and implement sustainable practices throughout the entire life cycle of the axle shafts.

- Supply Chain Sustainability: Promoting sustainability in axle shaft production involves considering the sustainability practices of suppliers and fostering sustainable partnerships throughout the supply chain. Encouraging suppliers to adhere to environmental standards, promoting responsible sourcing of raw materials, and ensuring ethical labor practices contribute to a more sustainable overall production process.

It’s important to note that specific eco-friendly and sustainable practices may vary among manufacturers and depend on factors such as the size of the production facility, available resources, and technological advancements. However, by incorporating these practices, axle shaft production can reduce its environmental impact, conserve resources, minimize waste, and contribute to a more sustainable automotive industry.

In summary, the eco-friendly and sustainable aspects of axle shaft production include material selection using recycled or sustainable materials, energy efficiency measures, waste reduction and recycling practices, water conservation efforts, emissions reduction strategies, life cycle assessment, and promoting supply chain sustainability. By adopting these practices, axle shaft manufacturers can contribute to a greener and more sustainable future.

What are the advantages of using high-performance or heavy-duty axle shafts?

Using high-performance or heavy-duty axle shafts can offer several advantages in terms of strength, durability, and performance. These specialized axle shafts are designed to handle increased torque loads, provide improved power delivery, and withstand the demands of challenging applications. Here’s a detailed explanation of the advantages of using high-performance or heavy-duty axle shafts:

- Increased Strength: High-performance or heavy-duty axle shafts are typically constructed from stronger materials, such as chromoly steel or alloy steel. These materials offer higher tensile and yield strength compared to standard axle shafts. The increased strength allows the shafts to handle higher torque loads without deformation or failure, providing enhanced reliability and durability.

- Improved Power Delivery: High-performance axle shafts are designed to provide more efficient power delivery from the drivetrain to the wheels. The enhanced strength and rigidity of these shafts minimize power loss due to torsional flex, ensuring that a greater percentage of the torque generated by the engine reaches the wheels. This results in improved acceleration, better throttle response, and enhanced overall performance.

- Enhanced Torsional Rigidity: Heavy-duty axle shafts are often engineered with increased torsional rigidity. This means they have reduced torsional flex or twisting under load. The improved torsional rigidity helps maintain consistent power transfer to the wheels, especially during high-torque situations or aggressive driving maneuvers. It contributes to better traction and stability, particularly in performance-oriented or off-road applications.

- Increased Durability: High-performance or heavy-duty axle shafts are designed to withstand the demands of challenging applications. They are engineered to handle increased loads, higher rotational speeds, and more extreme operating conditions. By providing greater durability, these axle shafts can withstand off-road obstacles, heavy payloads, or aggressive driving without premature wear or failure.

- Improved Off-Road Capability: High-performance or heavy-duty axle shafts are particularly beneficial in off-road applications. They can handle the additional stresses and forces encountered during off-road driving, such as uneven terrain, rock crawling, or high-speed desert runs. With increased strength and durability, these axle shafts reduce the risk of breakage, allowing off-road enthusiasts to explore challenging terrains with more confidence.

- Support for Vehicle Modifications: High-performance or heavy-duty axle shafts are often used in vehicles with significant modifications, such as increased engine power, larger tires, or suspension upgrades. These axle shafts can accommodate the additional torque loads and provide the necessary strength and reliability to support the modified drivetrain and suspension components.

It’s important to note that the advantages of high-performance or heavy-duty axle shafts are most noticeable in applications where the vehicle is subjected to increased torque loads, extreme conditions, or performance-oriented driving. In everyday driving scenarios with standard vehicles, the benefits may be less pronounced.

When considering high-performance or heavy-duty axle shafts, it’s crucial to ensure compatibility with other drivetrain components, such as the differential, wheel hubs, and braking system. Additionally, professional installation by experienced technicians is recommended to ensure proper fitment and compatibility.

Overall, high-performance or heavy-duty axle shafts offer increased strength, improved power delivery, enhanced durability, and better performance characteristics, making them a valuable upgrade for specific applications where increased performance, reliability, and off-road capability are desired.

How does axle shaft length and material affect a vehicle’s performance?

The length and material of an axle shaft can have an impact on a vehicle’s performance in several ways. Both factors play a role in determining the vehicle’s handling, power delivery, efficiency, and overall drivability. Here’s a detailed explanation of how axle shaft length and material affect a vehicle’s performance:

Axle Shaft Length:

The length of the axle shaft refers to the distance between the differential or transaxle and the wheel hub. The axle shaft length can influence the following aspects of a vehicle’s performance:

- Traction and Stability: A longer axle shaft can provide increased stability and traction, especially in situations where weight transfer occurs during acceleration or cornering. The longer length helps distribute the vehicle’s weight more evenly between the wheels, enhancing grip and stability.

- Turning Radius: The length of the axle shaft affects a vehicle’s turning radius. Generally, a shorter axle shaft allows for a tighter turning radius, making it easier to maneuver in tight spaces or negotiate sharp turns. On the other hand, a longer axle shaft may result in a larger turning radius, requiring more space for turning maneuvers.

- Ground Clearance: The length of the axle shaft can impact a vehicle’s ground clearance. A shorter axle shaft may provide higher ground clearance, which can be advantageous for off-road vehicles or those designed for rugged terrain. Conversely, a longer axle shaft may reduce ground clearance, potentially limiting the vehicle’s ability to navigate obstacles.

Axle Shaft Material:

The material used in the construction of an axle shaft can significantly influence a vehicle’s performance characteristics. Here are some ways in which axle shaft material can impact performance:

- Strength and Durability: The material of the axle shaft determines its strength and durability. High-strength materials, such as alloy steel or specialized composites, can withstand higher torque loads and provide enhanced durability, making them suitable for high-performance or heavy-duty applications. Stronger materials also contribute to improved reliability and reduced risk of axle shaft failure.

- Weight Reduction: The choice of lightweight materials, such as aluminum or carbon fiber, for the axle shaft can help reduce overall vehicle weight. A lighter axle shaft contributes to improved fuel efficiency, handling, and acceleration. It also reduces unsprung weight, which positively affects the vehicle’s suspension dynamics and responsiveness.

- Flexibility and Damping: Some axle shaft materials possess inherent flexibility or damping properties that can influence the vehicle’s ride quality and handling characteristics. Certain composite materials or designs can help absorb vibrations and shocks from the road surface, contributing to a smoother and more comfortable ride.

- Cost and Manufacturing: The choice of axle shaft material can impact manufacturing costs and feasibility. Some materials may be more expensive or require specialized manufacturing processes, affecting the overall cost of the vehicle. Additionally, material availability and ease of fabrication can influence the practicality of using certain materials for axle shaft construction.

It’s important to note that axle shaft length and material selection are typically determined by the vehicle manufacturer based on various considerations, including the intended purpose of the vehicle, performance targets, cost factors, and engineering requirements. Optimizing axle shaft length and material can contribute to achieving the desired balance of performance, handling, durability, and efficiency for a specific vehicle application.

editor by CX 2023-11-10

China Professional Intermediate Shaft of The Demultiplier Cover CZPT Truck Gearbox Parts Auxiliary Gearbox High-Quality Demultiplier Shaft China Gearboxes Parts Wheel Loader near me shop

Item Description

Pricey buddies!

My identify is Irina Mamoshina. Please spend a minute of your consideration : -).

Our organization HangZhou CZPT Global Trade Co., Ltd is engaged in the creation and sale of car parts for Chinese specific gear, engines and equipment assembly. We also create metal areas ourselves, these kinds of as gears, fingers, filters, and so on.

Our products incorporate:

— (Xugong) spare parts for frontelements for front-finish loaders:

LG918, LG936, LG956, LG958, LG968

— ZL30H, ZL50H, ZL50G, ZL60H, ZL968, ZL958

— FL935E, FL936, FL958G, FL956

— spare components for front loaders:

CLG856, ZL40B, ZL30E, ZL50C, ZL50EX, LG835

— CDM816, CDM835E, CDM853, CDM855E, CDM856E, CDM860.

We also provide the adhering to versions of equipment for sale: ZL930 ZL933 ZL936 ZL950 ZL953 ZL956.

In the attachment I ship images and movies from our creation, as well as some photos of products.

We provide loaders below our personal brand Hoadezu. Specialized info and photos in the attachment. The costs are for reference, you should specify them on ask for :-).

If you have a ask for, please ship it to me :-).

—

HangZhou CZPT Worldwide Trade Co., Ltd, Revenue Manager Irina Mamoshina.

Information to Travel Shafts and U-Joints

If you happen to be worried about the efficiency of your car’s driveshaft, you might be not by itself. A lot of automobile proprietors are unaware of the warning indications of a failed driveshaft, but being aware of what to seem for can assist you avoid high priced repairs. Here is a transient information on generate shafts, U-joints and servicing intervals. Shown below are crucial details to think about just before replacing a motor vehicle driveshaft.

Signs and symptoms of Driveshaft Failure

Pinpointing a faulty driveshaft is effortless if you’ve got at any time heard a strange sound from beneath your automobile. These appears are induced by worn U-joints and bearings supporting the push shaft. When they fail, the push shafts end rotating correctly, making a clanking or squeaking sound. When this transpires, you could listen to noise from the side of the steering wheel or ground.

In addition to noise, a defective driveshaft can cause your vehicle to swerve in tight corners. It can also lead to suspended bindings that restrict total handle. For that reason, you ought to have these indicators checked by a mechanic as before long as you notice them. If you observe any of the signs previously mentioned, your following step should be to tow your motor vehicle to a mechanic. To stay away from further trouble, make sure you’ve taken safety measures by checking your car’s oil amount.

In addition to these symptoms, you should also seem for any sounds from the drive shaft. The 1st point to look for is the squeak. This was brought on by extreme hurt to the U-joint hooked up to the drive shaft. In addition to noise, you must also seem for rust on the bearing cap seals. In intense instances, your auto can even shudder when accelerating.

Vibration while driving can be an early warning sign of a driveshaft failure. Vibration can be due to worn bushings, stuck sliding yokes, or even springs or bent yokes. Excessive torque can be induced by a worn heart bearing or a damaged U-joint. The car may make abnormal noises in the chassis system.

If you recognize these signs, it’s time to consider your auto to a mechanic. You need to examine frequently, particularly weighty vehicles. If you might be not positive what’s causing the noise, examine your car’s transmission, motor, and rear differential. If you suspect that a driveshaft demands to be replaced, a qualified mechanic can replace the driveshaft in your car.

Drive shaft variety

Driveshafts are used in numerous different kinds of cars. These contain four-wheel travel, entrance-engine rear-wheel push, bikes and boats. Every single kind of generate shaft has its possess goal. Beneath is an overview of the a few most common types of generate shafts:

The driveshaft is a round, elongated shaft that transmits torque from the engine to the wheels. Drive shafts typically have a lot of joints to compensate for changes in duration or angle. Some travel shafts also include connecting shafts and inner continual velocity joints. Some also incorporate torsional dampers, spline joints, and even prismatic joints. The most important thing about the driveshaft is that it performs a important position in transmitting torque from the engine to the wheels.

The drive shaft wants to be both light-weight and powerful to move torque. Whilst steel is the most commonly employed substance for automotive driveshafts, other resources this sort of as aluminum, composites, and carbon fiber are also generally utilised. It all depends on the goal and dimension of the motor vehicle. Precision Manufacturing is a great supply for OEM products and OEM driveshafts. So when you might be seeking for a new driveshaft, preserve these variables in thoughts when getting.

Cardan joints are one more common travel shaft. A common joint, also acknowledged as a U-joint, is a versatile coupling that permits one particular shaft to drive the other at an angle. This variety of travel shaft allows electrical power to be transmitted while the angle of the other shaft is continuously altering. While a gimbal is a good selection, it is not a ideal remedy for all programs.

CZPT, Inc. has point out-of-the-artwork machinery to services all types of drive shafts, from little vehicles to race vehicles. They provide a variety of demands, including racing, sector and agriculture. Whether you need a new drive shaft or a straightforward adjustment, the staff at CZPT can meet up with all your needs. You may be back on the road shortly!

U-joint

If your vehicle yoke or u-joint shows signs of dress in, it truly is time to change them. The least difficult way to exchange them is to adhere to the steps below. Use a big flathead screwdriver to take a look at. If you really feel any motion, the U-joint is faulty. Also, inspect the bearing caps for hurt or rust. If you cannot uncover the u-joint wrench, consider checking with a flashlight.

When inspecting U-joints, make certain they are properly lubricated and lubricated. If the joint is dry or poorly lubricated, it can rapidly fall short and trigger your vehicle to squeak whilst driving. Yet another signal that a joint is about to are unsuccessful is a sudden, abnormal whine. Check out your u-joints each and every yr or so to make sure they are in proper functioning order.

Whether your u-joint is sealed or lubricated will count on the make and model of your automobile. When your vehicle is off-road, you require to install lubricable U-joints for durability and longevity. A new driveshaft or derailleur will cost a lot more than a U-joint. Also, if you don’t have a very good understanding of how to change them, you may need to have to do some transmission work on your automobile.

When replacing the U-joint on the generate shaft, be positive to select an OEM replacement anytime attainable. Although you can simply mend or substitute the unique head, if the u-joint is not lubricated, you could require to change it. A broken gimbal joint can trigger problems with your car’s transmission or other critical factors. Replacing your car’s U-joint early can make certain its prolonged-expression performance.

One more alternative is to use two CV joints on the push shaft. Making use of a number of CV joints on the generate shaft helps you in situations the place alignment is hard or functioning angles do not match. This variety of driveshaft joint is much more high-priced and intricate than a U-joint. The disadvantages of utilizing numerous CV joints are added duration, excess weight, and diminished working angle. There are numerous motives to use a U-joint on a travel shaft.

upkeep interval

Examining U-joints and slip joints is a critical part of regimen maintenance. Most automobiles are equipped with lube fittings on the driveshaft slip joint, which should be checked and lubricated at every oil modify. CZPT experts are effectively-versed in axles and can easily identify a bad U-joint dependent on the sound of acceleration or shifting. If not repaired correctly, the drive shaft can tumble off, requiring high-priced repairs.

Oil filters and oil modifications are other components of a vehicle’s mechanical method. To avoid rust, the oil in these parts should be changed. The identical goes for transmission. Your vehicle’s driveshaft ought to be inspected at minimum each and every sixty,000 miles. The vehicle’s transmission and clutch need to also be checked for dress in. Other elements that need to be checked include PCV valves, oil traces and connections, spark plugs, tire bearings, steering gearboxes and brakes.

If your motor vehicle has a manual transmission, it is greatest to have it serviced by CZPT’s East Lexington authorities. These solutions must be performed each two to four several years or every 24,000 miles. For greatest results, refer to the owner’s handbook for suggested maintenance intervals. CZPT experts are skilled in axles and differentials. Typical upkeep of your drivetrain will keep it in great operating purchase.