Product Description

Product Description

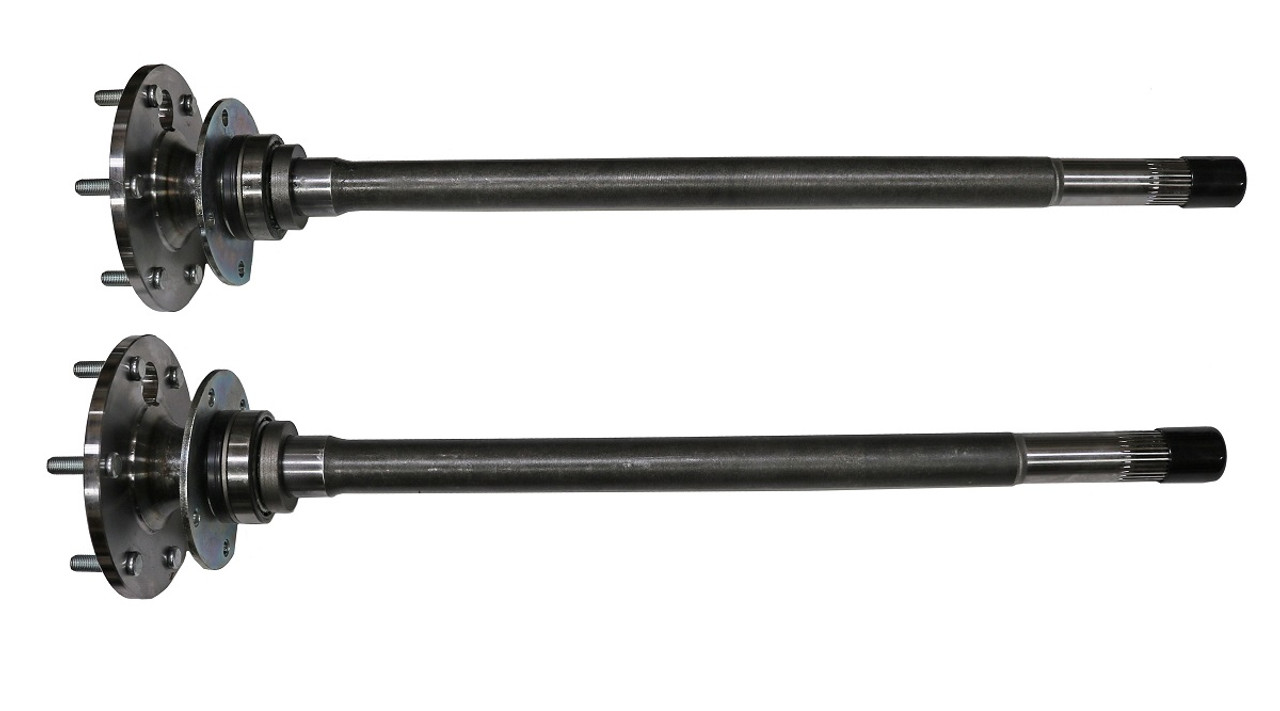

INPUT SHAFT for CZPT TRUCK ANKAI AXLE 457

Our company specilize in dealing with all kinds of truck spare parts for beiben CZPT CZPT CZPT ouman hongyan

from cab parts to chassis parts ,engine parts,gearbox parts,suspensiton parts,all kinds of engine mounting,bracket,leaf spring.We have factory to produce all kinds of alternator,starter,clutch plate,clutch cover,radiator,intercooler,can prodcue different size fuel tank according to customer requirement.

If you demand or are intersted in our products,please do not hesistate to contact with me,we will give best service with good quality and good price.Wish we can have long term copperation

Detailed Photos

Packaging & Shipping

1. Packaging details: carton and wooden box packaging,woven bag,brown box, or

according to customer requirements.

2. Delivery Period: 7-30 working days after

receiving 30% deposit byTT

3. Port: HangZhou Port,China.

4. Transport: By sea, by

air,DHL,FEDEX,UPS,TNT,

FAQ

1.Q:About the payment term.

A: We can accept TT,LC,PAYPAL,WESTERNUION,and so on

2.Q:About the Quality and price

A: We supply good quality products to all our customers,give the competitive price.

3.Q:About the warranty period

A:At least half year, some parts are even longer.

4. Q:How to make order ?

A:Customer can contact us online,or send email with detail inquiry list,then we can reply soon

5.Q:About the discount

A:If the quantity large,we will give resonalbe discount.And for long time cooperation customer,we can give credit support

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free Change for Quality Problem |

|---|---|

| Material: | Steel |

| Car Make: | Beiben |

| Position: | Chassis |

| OEM: | No |

| Type: | Input Shaft |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | |

|---|

Can you explain the impact of axle shaft materials on weight and strength?

The choice of material for axle shafts has a significant impact on both weight and strength characteristics. Different materials offer varying levels of strength-to-weight ratios, which can influence the overall performance and durability of the axle shafts. Here’s an explanation of how axle shaft materials affect weight and strength:

- Steel: Steel is a commonly used material for axle shafts due to its high strength and durability. Steel axle shafts are known for their excellent load-bearing capacity and resistance to bending and torsional forces. However, steel is relatively heavy compared to other materials, which can contribute to increased overall weight of the vehicle. The weight of steel axle shafts can affect the vehicle’s fuel efficiency and handling characteristics.

- Alloy Steel: Alloy steel is a type of steel that has been mixed with other elements to enhance specific properties. By adding elements such as chromium, molybdenum, or nickel, alloy steel can achieve improved strength and hardness compared to traditional steel. This allows for the production of lighter and stronger axle shafts compared to conventional steel, providing a balance between weight reduction and structural integrity.

- Aluminum: Aluminum is a lightweight material known for its excellent strength-to-weight ratio. When used in axle shafts, aluminum can significantly reduce the weight of the component, which can lead to benefits such as improved fuel efficiency and handling. However, aluminum axle shafts may not be as strong as steel shafts and can be more susceptible to bending or deformation under high loads or extreme conditions.

- Composite Materials: Composite materials, such as carbon fiber reinforced polymers (CFRP), are increasingly being explored for axle shaft applications. CFRP composites offer high strength and light weight, making them attractive for weight reduction purposes. These materials can provide comparable or even superior strength compared to steel while significantly reducing the overall weight of the axle shafts. However, composite materials often come with higher production costs and may require specialized manufacturing techniques.

Overall, the choice of axle shaft material involves a trade-off between weight reduction and strength requirements. Steel offers excellent strength but comes with higher weight, while materials like aluminum and composites offer weight savings at the expense of some strength characteristics. The selection of the most suitable material depends on various factors, including the vehicle’s intended use, load requirements, cost considerations, and desired performance attributes.

In summary, the impact of axle shaft materials on weight and strength is significant. Steel provides high strength but adds weight, alloy steel offers a balance between strength and weight, aluminum reduces weight but may sacrifice some strength, and composite materials provide strength and weight advantages but at potentially higher costs. Manufacturers consider these factors when selecting axle shaft materials to achieve the desired balance of weight reduction, strength, and overall performance in vehicles.

How does axle shaft quality impact the overall durability of a vehicle?

The quality of axle shafts has a significant impact on the overall durability of a vehicle. Axle shafts play a crucial role in transmitting power from the drivetrain to the wheels and supporting the weight of the vehicle. Here’s a detailed explanation of how axle shaft quality affects the durability of a vehicle:

- Strength and Load Capacity: High-quality axle shafts are typically constructed from strong and durable materials, such as forged steel or alloy steel. These materials offer increased tensile and yield strength, allowing the axle shafts to handle higher torque loads and support the weight of the vehicle more effectively. Axle shafts with higher load capacities and structural integrity are less prone to bending, breaking, or premature failure, ensuring long-term durability.

- Resistance to Fatigue: Axle shafts are subjected to repeated and varying loads during vehicle operation, which can lead to metal fatigue over time. High-quality axle shafts are designed and manufactured to withstand these cyclic loads without developing cracks or fractures. They undergo rigorous testing and quality control processes to ensure resistance to fatigue, enhancing the overall durability of the vehicle.

- Corrosion Resistance: Axle shafts are exposed to various environmental factors, including moisture, road salt, and debris. High-quality axle shafts often feature protective coatings or treatments, such as galvanization or specialized finishes, to enhance corrosion resistance. These coatings prevent rust and corrosion from compromising the structural integrity of the axle shafts, contributing to their long-term durability.

- Precision Engineering: Axle shafts with superior quality are precisely engineered to meet strict tolerances and specifications. They are manufactured using advanced techniques, such as forging or CNC machining, to ensure dimensional accuracy and proper fitment with other drivetrain components. Precise engineering eliminates excessive play or misalignment, reducing stress on the axle shafts and enhancing the overall durability of the vehicle.

- Heat Treatment: High-quality axle shafts often undergo specialized heat treatment processes, such as induction hardening or tempering. These heat treatment techniques improve the hardness and strength of the axle shafts, making them more resistant to wear, deformation, and surface damage. Heat-treated axle shafts exhibit enhanced durability and longevity, even under demanding driving conditions.

- Manufacturer Reputation: The reputation of the axle shaft manufacturer is also a crucial factor in determining the quality and durability of the product. Reputable manufacturers with a history of producing reliable and high-quality axle shafts are more likely to deliver durable and long-lasting components. Choosing axle shafts from trusted manufacturers reduces the risk of premature failure and ensures higher overall vehicle durability.

It’s important to note that the durability of a vehicle is influenced by various other factors, including proper maintenance, driving conditions, and overall vehicle design. However, the quality of axle shafts significantly contributes to the vehicle’s ability to withstand demanding loads, harsh environments, and extended service life.

When replacing or upgrading axle shafts, it is crucial to select high-quality components that match the vehicle’s specifications and intended use. Professional installation by experienced technicians is recommended to ensure proper fitment and compatibility, further enhancing the durability and performance of the vehicle.

In summary, axle shaft quality directly impacts the overall durability of a vehicle by providing increased strength, resistance to fatigue and corrosion, precision engineering, heat treatment, and the reliability associated with reputable manufacturers. Investing in high-quality axle shafts contributes to a more durable and reliable vehicle that can withstand the demands of various driving conditions and extended use.

What are the components of an axle shaft assembly and their functions?

An axle shaft assembly consists of several components that work together to facilitate the transmission of power from the differential to the wheels. Each component plays a specific role in ensuring efficient power transfer and supporting the functionality of the axle shaft assembly. Here are the main components and their functions:

1. Axle Shaft:

The axle shaft itself is the main component of the assembly. It is a long, cylindrical shaft that connects the differential or transaxle to the wheels. The primary function of the axle shaft is to transmit rotational power from the differential to the wheels, enabling them to rotate and propelling the vehicle forward or backward.

2. Differential Side Gears or Output Shafts:

The axle shaft assembly is connected to the differential through side gears or output shafts. These are gear-like components that are part of the differential mechanism. The side gears or output shafts engage with the axle shafts, providing a solid mechanical connection. They allow the rotational force from the differential to be transmitted to the axle shafts, initiating power transfer to the wheels.

3. Constant Velocity (CV) Joints:

In many modern vehicles, especially those with front-wheel drive or independent suspension systems, the axle shaft assembly incorporates constant velocity (CV) joints. CV joints allow for smooth power transfer and accommodate changes in axle angle and length due to suspension movement and steering. They provide flexibility and reduce vibrations during power transmission. CV joints consist of inner and outer joints with ball bearings and protective boots filled with grease to maintain lubrication and prevent contamination.

4. Wheel Hubs:

At the outer ends of the axle shaft assembly, wheel hubs are attached. Wheel hubs serve as the connection points for the wheels. They provide a mounting surface for the wheels and ensure proper alignment and rotation. The axle shafts transmit the rotational power from the differential to the wheel hubs, causing the wheels to rotate. Wheel hubs often incorporate bearings to allow smooth rotation and reduce friction.

5. Bearings:

Bearings are crucial components within the axle shaft assembly. They support the rotating motion of the axle shafts and the wheel hubs. The bearings reduce friction and allow the axle shafts and wheel hubs to rotate freely. They are typically designed to withstand the forces and loads encountered during vehicle operation and contribute to smooth and efficient power transmission.

6. Seals and Retaining Devices:

To prevent the entry of contaminants and retain lubrication, seals are used in the axle shaft assembly. Seals are placed at various points along the assembly to protect the bearings, CV joints, and other critical components from dirt, moisture, and debris. Additionally, retaining devices such as circlips or snap rings are used to secure the axle shafts, CV joints, or bearings within their respective housings, ensuring proper alignment and preventing unintended disassembly.

These are the key components typically found in an axle shaft assembly. The combination of these components allows for effective power transmission, smooth rotation, support for the wheels, and protection of critical parts, ensuring the overall functionality and longevity of the axle shaft assembly.

editor by CX 2024-03-12

China high quality CZPT Schachman Gearbox Axle Counter Input Shaft of Automobile axle alignment

Product Description

Product Description

Gearbox Parts Input Shaft, also known as the “input shaft”, is a key component in a car’s transmission and is closely connected to the clutch. Its main function is to effectively transmit the power generated by the engine to the gearbox through the control of the clutch.

Detailed Photos

Product Parameters

| Product Name | HOWO Schachman Gearbox Axle Counter Input Shaft of Automobile |

| Core Components | Gear, Gearbox, Motor, Pump, Engine, Reducer |

| Place of Origin | ZheJiang ,China |

| Condition | New |

| Structure | Shaft |

| Coatings | None |

| Torque Capacity | Stable |

| Processing Type | Lathing, Hobbing, Skiving |

| Module | M0.4-M3.0 / DP48 |

| Pressure Angle | 20 Degree |

| Tolerance | 0.001mm-0.01mm-0.1mm |

| Precision Grade | JIS3-5/DIN7-9/ISO7-9 |

| Teeth Profile | Straight, Slanted, Helical, Spiral, Helix Teeth, Spline |

| Application | Machinery Accessories, Industrial Machine, Transmission Equipment |

| Size | Customer’s Requirements |

| Machining Equipment | CNC Machine Centres |

| Quality | 100% Inspection |

| Packaging | Wooden box, carton or customized |

| Port | HangZhou,ZheJiang |

| Warranty | 12 Months |

Our Advantages

1. We have been committed to the heavy truck accessories industry for more than 10 years. The company’s professional team can quickly match any products you need, saving you purchasing time;

2. Excellent product quality is the foundation of our company and the cornerstone on which our company has always relied for survival;

3.Our company has formed a complete supply chain, which can process customer orders within 2 hours, arrange production plans and ship goods as soon as possible;

4. Our company has complete after-sales guarantee, and excellent after-sales service is the main factor for us to reach follow-up cooperation with customers.

Company Profile

ZheJiang Yontan Import and Export Co., Ltd. was established in HangZhou, the capital of ZheJiang Province, a famous national historical and cultural city with profound heritage. The company is mainly engaged in the export of complete vehicles of SINOTRUC, HOWO, SHACMAN, FOTON, FAW, XIHU (WEST LAKE) DIS., XIHU (WEST LAKE) DIS.FENG and other brands. It is engaged in the export sales of a full range of truck accessories and assemblies. The products distributed by the company are mainly supplied to major domestic transportation units, oil and gas transportation teams, municipal engineering fleets and civil engineering fleets, as well as major foreign construction companies and transportation companies.

On the basis of the continuous development of the company’s business, we are committed to exploring the international market. So far, our market has covered China, Eastern Europe, the Middle East, Africa, Southeast Asia, South America and other countries and regions. Our integrity is everywhere and we are deeply trusted by customers. Our company has a large warehouse and a professional management team, which can quickly find suitable parts for customers, and can provide services such as good packaging, safe storage, and fast transportation to meet the diverse needs of customers at any time.

Certifications

Customer Visit

FAQ

1. About the condition of the truck:

Each product will have a test report.We guarantee that the product is in good condition.

2. About delivery:

Divided into flat frame container, bulk carrier, roll-on – roll ship

3.MOQ:

1 group

4. About OEM:

Welcome, you can send your own designed LOGO, we can open a new mold for you to print or emboss any LOGO.

5. Terms of payment:

For sample orders, you can use telegraphic transfer, sight L/C, Western Union, Paypal, MoneyGram, Alipay or credit card.

6. About delivery time:

The exact delivery time depends on the item you order and the quantity.

7. About Us:

We have a professional vehicle renewal team, 1 for every truck Test report.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Good |

|---|---|

| Warranty: | 12 Months |

| Type: | Carrosserie |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the impact of axle shaft materials on weight and strength?

The choice of material for axle shafts has a significant impact on both weight and strength characteristics. Different materials offer varying levels of strength-to-weight ratios, which can influence the overall performance and durability of the axle shafts. Here’s an explanation of how axle shaft materials affect weight and strength:

- Steel: Steel is a commonly used material for axle shafts due to its high strength and durability. Steel axle shafts are known for their excellent load-bearing capacity and resistance to bending and torsional forces. However, steel is relatively heavy compared to other materials, which can contribute to increased overall weight of the vehicle. The weight of steel axle shafts can affect the vehicle’s fuel efficiency and handling characteristics.

- Alloy Steel: Alloy steel is a type of steel that has been mixed with other elements to enhance specific properties. By adding elements such as chromium, molybdenum, or nickel, alloy steel can achieve improved strength and hardness compared to traditional steel. This allows for the production of lighter and stronger axle shafts compared to conventional steel, providing a balance between weight reduction and structural integrity.

- Aluminum: Aluminum is a lightweight material known for its excellent strength-to-weight ratio. When used in axle shafts, aluminum can significantly reduce the weight of the component, which can lead to benefits such as improved fuel efficiency and handling. However, aluminum axle shafts may not be as strong as steel shafts and can be more susceptible to bending or deformation under high loads or extreme conditions.

- Composite Materials: Composite materials, such as carbon fiber reinforced polymers (CFRP), are increasingly being explored for axle shaft applications. CFRP composites offer high strength and light weight, making them attractive for weight reduction purposes. These materials can provide comparable or even superior strength compared to steel while significantly reducing the overall weight of the axle shafts. However, composite materials often come with higher production costs and may require specialized manufacturing techniques.

Overall, the choice of axle shaft material involves a trade-off between weight reduction and strength requirements. Steel offers excellent strength but comes with higher weight, while materials like aluminum and composites offer weight savings at the expense of some strength characteristics. The selection of the most suitable material depends on various factors, including the vehicle’s intended use, load requirements, cost considerations, and desired performance attributes.

In summary, the impact of axle shaft materials on weight and strength is significant. Steel provides high strength but adds weight, alloy steel offers a balance between strength and weight, aluminum reduces weight but may sacrifice some strength, and composite materials provide strength and weight advantages but at potentially higher costs. Manufacturers consider these factors when selecting axle shaft materials to achieve the desired balance of weight reduction, strength, and overall performance in vehicles.

What are the advantages of using high-performance or heavy-duty axle shafts?

Using high-performance or heavy-duty axle shafts can offer several advantages in terms of strength, durability, and performance. These specialized axle shafts are designed to handle increased torque loads, provide improved power delivery, and withstand the demands of challenging applications. Here’s a detailed explanation of the advantages of using high-performance or heavy-duty axle shafts:

- Increased Strength: High-performance or heavy-duty axle shafts are typically constructed from stronger materials, such as chromoly steel or alloy steel. These materials offer higher tensile and yield strength compared to standard axle shafts. The increased strength allows the shafts to handle higher torque loads without deformation or failure, providing enhanced reliability and durability.

- Improved Power Delivery: High-performance axle shafts are designed to provide more efficient power delivery from the drivetrain to the wheels. The enhanced strength and rigidity of these shafts minimize power loss due to torsional flex, ensuring that a greater percentage of the torque generated by the engine reaches the wheels. This results in improved acceleration, better throttle response, and enhanced overall performance.

- Enhanced Torsional Rigidity: Heavy-duty axle shafts are often engineered with increased torsional rigidity. This means they have reduced torsional flex or twisting under load. The improved torsional rigidity helps maintain consistent power transfer to the wheels, especially during high-torque situations or aggressive driving maneuvers. It contributes to better traction and stability, particularly in performance-oriented or off-road applications.

- Increased Durability: High-performance or heavy-duty axle shafts are designed to withstand the demands of challenging applications. They are engineered to handle increased loads, higher rotational speeds, and more extreme operating conditions. By providing greater durability, these axle shafts can withstand off-road obstacles, heavy payloads, or aggressive driving without premature wear or failure.

- Improved Off-Road Capability: High-performance or heavy-duty axle shafts are particularly beneficial in off-road applications. They can handle the additional stresses and forces encountered during off-road driving, such as uneven terrain, rock crawling, or high-speed desert runs. With increased strength and durability, these axle shafts reduce the risk of breakage, allowing off-road enthusiasts to explore challenging terrains with more confidence.

- Support for Vehicle Modifications: High-performance or heavy-duty axle shafts are often used in vehicles with significant modifications, such as increased engine power, larger tires, or suspension upgrades. These axle shafts can accommodate the additional torque loads and provide the necessary strength and reliability to support the modified drivetrain and suspension components.

It’s important to note that the advantages of high-performance or heavy-duty axle shafts are most noticeable in applications where the vehicle is subjected to increased torque loads, extreme conditions, or performance-oriented driving. In everyday driving scenarios with standard vehicles, the benefits may be less pronounced.

When considering high-performance or heavy-duty axle shafts, it’s crucial to ensure compatibility with other drivetrain components, such as the differential, wheel hubs, and braking system. Additionally, professional installation by experienced technicians is recommended to ensure proper fitment and compatibility.

Overall, high-performance or heavy-duty axle shafts offer increased strength, improved power delivery, enhanced durability, and better performance characteristics, making them a valuable upgrade for specific applications where increased performance, reliability, and off-road capability are desired.

What is the purpose of an axle shaft in a vehicle’s drivetrain?

An axle shaft plays a crucial role in a vehicle’s drivetrain by transmitting rotational power from the differential to the wheels. It serves as a mechanical link between the differential and the wheels, allowing the transfer of torque and enabling the wheels to rotate.

1. Power Transmission:

The primary purpose of an axle shaft is to transmit power from the differential to the wheels. In a rear-wheel-drive vehicle, the axle shafts connect the differential to the rear wheels, while in a front-wheel-drive vehicle, they connect the differential or transaxle to the front wheels. When the engine generates torque, it is transferred to the transmission or transaxle, and then to the differential. The differential splits the torque between the two axle shafts, which then deliver the power to the respective wheels. This allows the wheels to rotate and propel the vehicle forward or backward.

2. Wheel Support and Suspension:

Axle shafts also provide support for the vehicle’s wheels and are an integral part of the suspension system. They bear the weight of the vehicle and help maintain proper wheel alignment and geometry. Axle shafts are designed to withstand the vertical load exerted by the vehicle’s weight and the lateral forces encountered during turns or maneuvering. By providing structural support and connection between the wheels and the drivetrain, axle shafts contribute to the overall stability, handling, and control of the vehicle.

3. Differential Functionality:

Axle shafts are essential for the proper functioning of the differential. The differential allows the wheels to rotate at different speeds while maintaining power distribution. As the vehicle negotiates turns, the inside wheels travel a shorter distance than the outside wheels. The axle shafts, connected to the differential, enable this speed differentiation by allowing the wheels to rotate independently. This differential action helps improve maneuverability, reduce tire wear, and enhance traction by allowing the wheels to maintain proper contact with the road surface.

4. Torque and Load Handling:

Axle shafts are designed to handle the torque and loads generated by the engine and transmitted through the drivetrain. They are engineered to withstand the rotational forces and torsional stress, ensuring efficient power transfer to the wheels. Axle shafts are made from durable materials, such as steel or other high-strength alloys, to withstand these forces and provide reliable performance under various driving conditions.

In summary, the purpose of an axle shaft in a vehicle’s drivetrain is to transmit rotational power from the differential to the wheels. They enable power transfer, provide support for the wheels, contribute to the functionality of the differential, and handle the torque and loads generated by the drivetrain. Axle shafts are essential components that play a vital role in the overall performance, functionality, and stability of a vehicle.

editor by CX 2024-03-04

China OEM Heavy Truck Rear Axle Parts 2510zhs01-057 Input Shaft for CZPT Truck with Hot selling

Solution Description

Large Truck Rear Axle Components 2510ZHS01-057 enter shaft for XIHU (WEST LAKE) DIS.FENG truck

Merchandise Parameters

Detailed Pictures

Packaging & Delivery

Our Rewards

HangZhou Sero Import&Export Co.,Ltd. is found in HangZhou city which is a comprehensive investing organization that manages all heavy obligation truck and light truck automobile areas.

We are the approved vendor of CZPT , deal all sequence of CZPT types (HOWO,A7,T5G,T7H,70 mining dump truck and etc.) , also engaged in SHACMAN,FOTON,FAW,XIHU (WEST LAKE) DIS.,XIHU (WEST LAKE) DIS.FENG,JAC,XIHU (WEST LAKE) DIS.N hefty responsibility and light-weight vehicles , we supply authentic and right after the market place and quality OEM areas .

Our merchandise have been exported to numerous countries in the globe with substantial good quality and competitive value and are well regarded both domestic and abroad.We sincerely guarantees to all clients and partners to give exceptional goods, perform together for frequent advancement.

Wrestle, integrity, thanksgiving, good quality is our constant pursuit.

FAQ

one. Q: Are you a maker or trading business?A: We are company.

2. Q: What about your items quality? A:”Good quality is precedence. ” We often attach wonderful value to top quality managing from the very beginning.

3.Q:What payment do you acknowledge? A: T/T, L/C, Trade assurance

Driveshaft structure and vibrations linked with it

The composition of the generate shaft is critical to its efficiency and trustworthiness. Push shafts typically have claw couplings, rag joints and universal joints. Other travel shafts have prismatic or splined joints. Find out about the diverse kinds of drive shafts and how they function. If you want to know the vibrations linked with them, go through on. But 1st, let us determine what a driveshaft is.

transmission shaft

As the demand on our cars carries on to increase, so does the demand from customers on our push methods. Increased CO2 emission requirements and stricter emission requirements increase the anxiety on the generate system even though improving comfort and ease and shortening the turning radius. These and other unfavorable effects can spot important stress and wear on factors, which can direct to driveshaft failure and increase car basic safety risks. Therefore, the generate shaft must be inspected and changed routinely.

Dependent on your product, you may possibly only require to replace one particular driveshaft. Nonetheless, the expense to exchange equally driveshafts ranges from $650 to $1850. In addition, you may possibly incur labor charges ranging from $140 to $250. The labor cost will rely on your vehicle product and its drivetrain sort. In basic, nonetheless, the price of replacing a driveshaft ranges from $470 to $1850.

Regionally, the automotive driveshaft marketplace can be divided into 4 major marketplaces: North America, Europe, Asia Pacific, and Rest of the Planet. North The us is predicted to dominate the industry, whilst Europe and Asia Pacific are anticipated to grow the quickest. Furthermore, the market place is envisioned to increase at the greatest charge in the foreseeable future, pushed by financial development in the Asia Pacific region. Moreover, most of the cars sold globally are produced in these locations.

The most critical function of the driveshaft is to transfer the electrical power of the engine to valuable operate. Push shafts are also identified as propeller shafts and cardan shafts. In a vehicle, a propshaft transfers torque from the motor, transmission, and differential to the front or rear wheels, or the two. Owing to the complexity of driveshaft assemblies, they are crucial to automobile basic safety. In addition to transmitting torque from the engine, they have to also compensate for deflection, angular alterations and length changes.

sort

Different types of generate shafts consist of helical shafts, gear shafts, worm shafts, planetary shafts and synchronous shafts. Radial protruding pins on the head give a rotationally protected connection. At minimum a single bearing has a groove extending along its circumferential duration that makes it possible for the pin to move through the bearing. There can also be two flanges on every single finish of the shaft. Dependent on the software, the shaft can be set up in the most convenient spot to perform.

Propeller shafts are generally manufactured of substantial-quality metal with large distinct power and modulus. Nonetheless, they can also be created from sophisticated composite materials this sort of as carbon fiber, Kevlar and fiberglass. One more kind of propeller shaft is created of thermoplastic polyamide, which is rigid and has a substantial energy-to-weight ratio. Equally push shafts and screw shafts are utilised to drive automobiles, ships and motorcycles.

Sliding and tubular yokes are typical elements of travel shafts. By design, their angles need to be equivalent or intersect to supply the proper angle of procedure. Except if the working angles are equivalent, the shaft vibrates twice per revolution, creating torsional vibrations. The very best way to stay away from this is to make certain the two yokes are effectively aligned. Crucially, these components have the identical working angle to make sure smooth electrical power stream.

The variety of push shaft differs in accordance to the kind of motor. Some are geared, while other folks are non-geared. In some situations, the push shaft is fixed and the motor can rotate and steer. Alternatively, a flexible shaft can be utilized to management the speed and route of the push. In some programs where linear electrical power transmission is not attainable, adaptable shafts are a useful alternative. For example, adaptable shafts can be employed in transportable units.

place up

The design of the drive shaft has numerous rewards more than bare metal. A shaft that is versatile in a number of instructions is less difficult to preserve than a shaft that is rigid in other directions. The shaft entire body and coupling flange can be produced of different resources, and the flange can be created of a various substance than the main shaft body. For illustration, the coupling flange can be manufactured of metal. The primary shaft human body is if possible flared on at least 1 end, and the at minimum a single coupling flange includes a very first generally frustoconical projection extending into the flared stop of the primary shaft human body.

The normal stiffness of fiber-dependent shafts is attained by the orientation of parallel fibers along the size of the shaft. However, the bending stiffness of this shaft is decreased owing to the adjust in fiber orientation. Because the fibers proceed to travel in the very same path from the first conclude to the second finish, the reinforcement that will increase the torsional stiffness of the shaft is not afflicted. In distinction, a fiber-based mostly shaft is also adaptable since it employs ribs that are about ninety levels from the centerline of the shaft.

In addition to the helical ribs, the generate shaft one hundred could also include reinforcing components. These reinforcing factors keep the structural integrity of the shaft. These reinforcing elements are named helical ribs. They have ribs on equally the outer and interior surfaces. This is to avoid shaft breakage. These factors can also be formed to be adaptable adequate to accommodate some of the forces created by the drive. Shafts can be designed using these strategies and produced into worm-like generate shafts.

vibration

The most frequent result in of travel shaft vibration is incorrect set up. There are 5 typical sorts of driveshaft vibration, each and every associated to installation parameters. To avoid this from occurring, you should understand what causes these vibrations and how to resolve them. The most typical types of vibration are detailed underneath. This report describes some frequent push shaft vibration remedies. It may possibly also be useful to contemplate the tips of a professional vibration technician for travel shaft vibration management.

If you might be not certain if the issue is the driveshaft or the motor, attempt turning on the stereo. Thicker carpet kits can also mask vibrations. However, you must speak to an expert as shortly as achievable. If vibration persists following vibration-associated repairs, the driveshaft demands to be changed. If the driveshaft is even now beneath guarantee, you can fix it yourself.

CV joints are the most widespread result in of 3rd-purchase driveshaft vibration. If they are binding or fall short, they need to have to be changed. Alternatively, your CV joints might just be misaligned. If it is loose, you can verify the CV connector. Another common lead to of drive shaft vibration is improper assembly. Improper alignment of the yokes on the two ends of the shaft can cause them to vibrate.

Incorrect trim top can also cause driveshaft vibration. Proper trim height is needed to avoid generate shaft wobble. Regardless of whether your automobile is new or aged, you can execute some simple fixes to minimize difficulties. 1 of these solutions involves balancing the drive shaft. First, use the hose clamps to attach the weights to it. Subsequent, connect an ounce of weight to it and spin it. By performing this, you decrease the frequency of vibration.

value

The international driveshaft marketplace is expected to exceed (xxx) million USD by 2028, growing at a compound once-a-year progress charge (CAGR) of XX%. Its soaring growth can be attributed to many aspects, including escalating urbanization and R&D investments by foremost marketplace gamers. The report also involves an in-depth investigation of crucial marketplace traits and their affect on the industry. Additionally, the report provides a comprehensive regional examination of the Driveshaft Market place.

The price of replacing the generate shaft is dependent on the variety of fix essential and the trigger of the failure. Typical mend charges variety from $three hundred to $750. Rear-wheel generate autos usually price much more. But entrance-wheel travel vehicles price much less than four-wheel push autos. You could also pick to try out repairing the driveshaft by yourself. Nonetheless, it is important to do your analysis and make positive you have the necessary equipment and products to complete the occupation effectively.

The report also handles the competitive landscape of the Drive Shafts market place. It contains graphical representations, comprehensive figures, management insurance policies, and governance components. Furthermore, it contains a comprehensive value examination. In addition, the report presents sights on the COVID-19 marketplace and foreseeable future developments. The report also offers useful information to help you decide how to compete in your sector. When you get a report like this, you are introducing trustworthiness to your work.

A top quality driveshaft can enhance your sport by making sure distance from the tee and enhancing responsiveness. The new substance in the shaft development is lighter, more powerful and far more responsive than at any time before, so it is getting to be a important component of the driver. And there are a selection of possibilities to match any funds. The primary aspect to take into account when purchasing a shaft is its good quality. Nevertheless, it’s critical to observe that quality isn’t going to occur cheap and you should constantly decide on an axle dependent on what your spending budget can deal with.