Product Description

SHINE Motors

Product Description

1.Summarize

Y series is a general purpose fully enclosed self-fan-cooled squirrel-cage three-phase asynchronous motor, which is a new generation of basic series of unified design in our country, and a replacement of JO2 series.

Y series motors have the advantages of high efficiency, energy saving, good performance, low noise, low vibration, high reliability, power levels of each installation size in line with IEC standards, easy to use and maintain. The protection level is IP44.

Y series motors are suitable for general places without flammable, explosive or corrosive gases and machinery without special requirements, such as: metal cutting machine tools, pumps, fans, transportation machinery, mixers, agricultural machinery, food machinery, etc. Because the motor has better starting performance, it is also suitable for certain machinery with higher torque requirements, such as compressors.

The rated voltage of the Y-series motor is 380V and the rated frequency is 50Hz.

2.Y Series motor Technical data (1000V)

| Model number

|

Kw |

A |

r/min |

% |

cosø |

Mmax Mn |

CZPT Mn |

lst ln |

J(motor) kg.m2 |

J() kg.m2 |

kg |

|

Y710-4 |

2500 |

170 |

1493 |

95.8 |

0.86 |

1.8 |

0.5 |

6.5 |

110 |

490 |

10500 |

|

Y710-4 |

2800 |

190 |

1493 |

95.9 |

0.86 |

1.8 |

0.5 |

6.5 |

120 |

560 |

11000 |

|

Y710-4 |

3150 |

210 |

1493 |

96 |

0.86 |

1.8 |

0.5 |

6.5 |

130 |

660 |

11500 |

|

Y710 4 |

3550 |

235 |

1493 |

96.1 |

0.86 |

1.8 |

0.5 |

6.5 |

150 |

780 |

12000 |

|

Y800-4 |

4000 |

264 |

1494 |

96.2 |

0.87 |

1.8 |

0.5 |

6.5 |

230 |

540 |

13000 |

|

Y800-4 |

4500 |

298 |

1494 |

96.2 |

0.87 |

1.8 |

0.5 |

6.5 |

250 |

740 |

13500 |

|

Y800-4 |

5000 |

328 |

1494 |

96.3 |

0.87 |

1.8 |

0.5 |

6.5 |

275 |

750 |

14000 |

|

Y800-4 |

5600 |

365 |

1494 |

96.3 |

0.87 |

1.8 |

0.5 |

6.5 |

300 |

800 |

15000 |

|

Y900-4 |

8300 |

416 |

1494 |

96.4 |

0.87 |

1.8 |

0.5 |

6.5 |

400 |

1070 |

16500 |

|

Y900-4 |

7100 |

466 |

1494 |

96.5 |

0.87 |

1.8 |

0.5 |

6.5 |

440 |

1070 |

17000 |

|

Y900-4 |

8000 |

523 |

1494 |

96.6 |

0.87 |

1.8 |

0.5 |

6.5 |

470 |

1070 |

17500 |

|

Y1000-4 |

9000 |

583 |

1494 |

96.7 |

0.87 |

1.8 |

0.5 |

6.5 |

630 |

1070 |

19000 |

|

Y1000-4 |

10000 |

643 |

1494 |

96.8 |

0.87 |

1.8 |

0.5 |

6.5 |

700 |

1200 |

20000 |

|

Y710-6 |

1800 |

126 |

993 |

95.4 |

0.84 |

1.8 |

0.6 |

6.5 |

145 |

1250 |

11000 |

|

Y710-6 |

2000 |

139 |

993 |

95.5 |

0.84 |

1.8 |

0.6 |

6.5 |

160 |

1350 |

11500 |

|

Y710-6 |

2240 |

155 |

993 |

95.6 |

0.84 |

1.8 |

0.6 |

6.5 |

170 |

1400 |

12000 |

|

Y710-6 |

2500 |

172 |

993 |

95.7 |

0.84 |

1.8 |

0.6 |

6.5 |

190 |

1500 |

12500 |

|

Y8OO-0 |

2800 |

187 |

995 |

95.8 |

0.84 |

1.8 |

0.6 |

6.5 |

310 |

2200 |

13000 |

|

Y800-6 |

3150 |

209 |

995 |

95.9 |

0.84 |

1.8 |

0.6 |

6.5 |

335 |

2350 |

13500 |

|

Y800-6 |

3550 |

235 |

995 |

96 |

0.84 |

1.8 |

0.6 |

6.5 |

370 |

2500 |

14000 |

|

Y900-6 |

4000 |

265 |

996 |

96.1 |

0.84 |

1.8 |

0.6 |

6.5 |

440 |

3500 |

15000 |

|

Y900-6 |

4500 |

289 |

996 |

96.1 |

0.86 |

1.8 |

0.6 |

6.5 |

490 |

3850 |

16000 |

|

Y900-6 |

5000 |

330 |

996 |

96.2 |

0.86 |

1.8 |

0.6 |

6.5 |

560 |

4400 |

17000 |

|

Y900-6 |

5600 |

362 |

996 |

96.2 |

0.86 |

1.8 |

0.6 |

6.5 |

630 |

4400 |

18000 |

|

Y1000-6 |

6300 |

412 |

996 |

96.3 |

0.86 |

1.8 |

0.6 |

6.5 |

930 |

4400 |

19000 |

|

Y1000-6 |

7100 |

457 |

996 |

96.4 |

0.86 |

1.8 |

0.6 |

6.5 |

1150 |

5000 |

20500 |

|

Y1000-6 |

8000 |

517 |

996 |

96.5 |

0.86 |

1.8 |

0.6 |

6.5 |

1150 |

5000 |

21000 |

|

Y710-8 |

1400 |

101 |

742 |

94.9 |

0.82 |

1.8 |

0.6 |

6.5 |

185 |

1900 |

11000 |

|

Y710-8 |

1600 |

116 |

742 |

95 |

0.82 |

1.8 |

0.6 |

6.5 |

210 |

2250 |

11500 |

|

Y710-8 |

1800 |

130 |

742 |

95.1 |

0.82 |

1.8 |

0.6 |

6.5 |

240 |

2650 |

12000 |

|

Y800-8 |

2000 |

140 |

745 |

95.2 |

0.83 |

1.8 |

0.6 |

6.5 |

370 |

4200 |

12500 |

|

Y800-8 |

2240 |

156 |

745 |

95.3 |

0.83 |

1.8 |

0.6 |

6.5 |

400 |

4700 |

13000 |

|

Y800-8 |

7500 |

173 |

745 |

95.4 |

0.83 |

1.8 |

0.6 |

6.5 |

450 |

4700 |

13800 |

|

Y800-8 |

2800 |

194 |

745 |

95.5 |

0.83 |

1.8 |

0.6 |

6.5 |

490 |

4700 |

14500 |

|

Y900-8 |

3150 |

217 |

746 |

95.6 |

0.84 |

1.8 |

0.6 |

6.5 |

830 |

4700 |

16500 |

|

Y900-8 |

3550 |

243 |

745 |

95.7 |

0.84 |

1.8 |

0.6 |

6.5 |

930 |

4700 |

17500 |

|

Y1000-8 |

4000 |

271 |

746 |

95.8 |

0.84 |

1.8 |

0.6 |

6.5 |

1230 |

4700 |

17500 |

|

Y1000-8 |

4500 |

302 |

746 |

95.9 |

0.84 |

1.8 |

0.6 |

6.5 |

1400 |

5600 |

18600 |

|

Y1000-8 |

6000 |

336 |

746 |

96 |

0.84 |

1.8 |

0.6 |

6.5 |

1600 |

6900 |

19600 |

|

Y710-10 |

1250 |

92 |

595 |

94.5 |

0.81 |

1.8 |

0.6 |

6 |

330 |

5200 |

11000 |

|

Y710-10 |

1400 |

103 |

595 |

94 |

0.81 |

1.8 |

0.6 |

6 |

380 |

5500 |

11500 |

|

Y710-10 |

1600 |

114 |

595 |

94.7 |

0.81 |

1.8 |

0.6 |

6 |

410 |

5500 |

12000 |

|

Y800-10 |

1800 |

130 |

595 |

94.8 |

0.82 |

1.8 |

0.6 |

6 |

570 |

5500 |

13000 |

|

Y800-10 |

2000 |

145 |

596 |

94.9 |

0.82 |

1.8 |

0.6 |

6 |

630 |

6200 |

13500 |

|

Y800-10 |

2240 |

161 |

595 |

96 |

0.82 |

1.8 |

0.6 |

6 |

710 |

6200 |

14000 |

|

Y900-10 |

2500 |

173 |

596 |

95.1 |

0.82 |

1.8 |

0.6 |

6 |

970 |

6200 |

15000 |

|

Y900-10 |

2800 |

193 |

596 |

95.2 |

0.82 |

1.8 |

0.6 |

6 |

1100 |

6200 |

16000 |

|

Y1000-10 |

3150 |

218 |

597 |

95.3 |

0.83 |

1.8 |

0.6 |

6 |

1230 |

6200 |

17000 |

|

Y1000-10 |

3550 |

243 |

597 |

95.4 |

0.83 |

1.8 |

0.6 |

6 |

1400 |

7700 |

18000 |

|

Y710-12 |

900 |

68 |

495 |

94 |

0.78 |

1.8 |

0.6 |

6 |

300 |

3500 |

11000 |

|

Y710-12 |

1000 |

76 |

495 |

94.1 |

0.78 |

1.8 |

0.6 |

6 |

330 |

4200 |

11500 |

|

Y710-12 |

1120 |

86 |

495 |

94.2 |

0.78 |

1.8 |

0.6 |

6 |

370 |

5000 |

12000 |

|

Y800-12 |

1250 |

96 |

495 |

94.3 |

0.78 |

1.8 |

0.6 |

6 |

490 |

7900 |

13000 |

|

Y800-12 |

1400 |

107 |

495 |

94.4 |

0.78 |

1.8 |

0.6 |

6 |

560 |

9900 |

14000 |

|

Y800-12 |

1600 |

122 |

495 |

94.4 |

0.79 |

1.8 |

0.6 |

6 |

660 |

9900 |

15000 |

|

Y900-12 |

1800 |

135 |

497 |

94.5 |

0.79 |

1.8 |

0.6 |

6 |

870 |

9900 |

15500 |

|

Y900-12 |

2000 |

149 |

497 |

94.6 |

0.79 |

1.8 |

0.6 |

6 |

940 |

9900 |

16000 |

|

Y900-12 |

2240 |

167 |

497 |

94.7 |

0.79 |

1.8 |

0.6 |

6 |

1030 |

9900 |

16500 |

|

Y1000-12 |

2500 |

184 |

498 |

94.8 |

0.8 |

1.8 |

0.6 |

6 |

1400 |

9900 |

18000 |

|

Y1000-12 |

2800 |

205 |

498 |

94.9 |

0.8 |

1.8 |

0.6 |

6 |

1600 |

11600 |

19000 |

|

Y1000-12 |

3150 |

230 |

498 |

95 |

0.8 |

1.8 |

0.6 |

6 |

1800 |

13700 |

20000 |

|

Y1000-12 |

3550 |

261 |

498 |

95.1 |

0.8 |

1.8 |

0.6 |

6 |

2000 |

15800 |

21000 |

|

Y710-16 |

500 |

45 |

371 |

92.8 |

0.72 |

1.8 |

0.6 |

6 |

400 |

3300 |

10500 |

|

Y710-16 |

560 |

50 |

371 |

92.9 |

0.72 |

1.8 |

0.6 |

6 |

450 |

3800 |

11000 |

|

Y710-16 |

630 |

55 |

371 |

93 |

0.72 |

1.8 |

0.6 |

6 |

500 |

4300 |

11500 |

|

Y710-16 |

710 |

60 |

371 |

93.1 |

0.72 |

1.8 |

0.6 |

6 |

550 |

4800 |

12000 |

|

Y800-16 |

800 |

67 |

371 |

93.2 |

0.72 |

1.8 |

0.6 |

6 |

700 |

5600 |

13000 |

|

Y800-16 |

900 |

74 |

371 |

93.3 |

0.72 |

1.8 |

0.6 |

6 |

750 |

6400 |

13500 |

|

Y800-16 |

1000 |

83 |

371 |

93.4 |

0.73 |

1.8 |

0.6 |

6 |

800 |

7200 |

14000 |

|

Y800-16 |

1120 |

92 |

371 |

93.5 |

0.73 |

1.8 |

0.6 |

6 |

850 |

8000 |

15000 |

|

Y900-16 |

1250 |

102 |

372 |

93.6 |

0.73 |

1.8 |

0.6 |

6 |

1080 |

9800 |

16000 |

|

Y900-16 |

1400 |

113 |

372 |

93.7 |

0.73 |

1.8 |

0.6 |

6 |

1200 |

11200 |

17000 |

|

Y900-16 |

1600 |

128 |

372 |

93.8 |

0.74 |

1.8 |

0.6 |

6 |

1300 |

13800 |

18000 |

|

Y1000-16 |

1800 |

133 |

372 |

93.9 |

0.74 |

1.8 |

0.6 |

6 |

1900 |

13900 |

19000 |

|

Y1000-16 |

2000 |

148 |

372 |

94 |

0.74 |

1.8 |

0.6 |

6 |

2100 |

16000 |

20000 |

|

Y1000-16 |

2240 |

166 |

372 |

94.1 |

0.74 |

1.8 |

0.6 |

6 |

2400 |

18000 |

21000 |

|

Y1000-16 |

2500 |

194 |

372 |

94.2 |

0.74 |

1.8 |

0.6 |

6 |

2500 |

24000 |

2200 |

Y Series motor Technical data (6000V)

| Model number

|

Kw |

A |

r/min |

% |

cosø |

Mmax Mn |

CZPT Mn |

lst ln |

J(motor) kg.m2 |

J() kg.m2 |

kg |

|

Y710-4 |

3150 |

350 |

1492 |

96.3 |

0.87 |

1.8 |

0.6 |

6.5 |

115 |

540 |

10500 |

|

Y710-4 |

3550 |

388 |

1492 |

96.3 |

0.87 |

1.8 |

0.5 |

6.5 |

129 |

600 |

11000 |

|

Y710-4 |

40000 |

434 |

1492 |

96.4 |

0.87 |

1.8 |

0.6 |

6.5 |

148 |

600 |

11600 |

|

Y710-4 |

4500 |

486 |

1492 |

96.4 |

0.87 |

1.8 |

0.5 |

6.5 |

185 |

600 |

12000 |

|

Y800-4 |

5000 |

546 |

1493 |

96.5 |

0.88 |

1.8 |

0.6 |

6.5 |

240 |

600 |

13000 |

|

Y800 4 |

5600 |

611 |

1493 |

90.5 |

0.88 |

1.8 |

0.6 |

6.5 |

260 |

730 |

13800 |

|

Y800-1 |

6300 |

687 |

1493 |

96.6 |

0.88 |

1.8 |

0.5 |

6.5 |

290 |

930 |

14500 |

|

V900-4 |

7100 |

775 |

1493 |

96.7 |

0.88 |

7.8 |

0.5 |

6.5 |

400 |

1120 |

16000 |

|

Y900-4 |

8000 |

867 |

1493 |

96.8 |

0.88 |

1.8 |

0.5 |

6.5 |

460 |

1120 |

17500 |

|

Y900-4 |

9000 |

977 |

1493 |

96.9 |

0.88 |

1.8 |

0.5 |

6.5 |

460 |

1120 |

18000 |

|

Y710-6 |

2240 |

248 |

993 |

96 |

0.86 |

1.8 |

0.6 |

6.5 |

175 |

1960 |

10500 |

|

Y710-6 |

2500 |

276 |

993 |

96.1 |

0.86 |

1.8 |

0.6 |

6.5 |

190 |

2200 |

11000 |

|

Y710-6 |

2800 |

309 |

993 |

96.1 |

0.86 |

1.8 |

0.6 |

6.5 |

210 |

2550 |

11500 |

|

Y710-6 |

3150 |

349 |

993 |

96.2 |

0.86 |

1.8 |

0.6 |

6.5 |

235 |

2950 |

12000 |

|

Y800-6 |

3550 |

390 |

994 |

96.2 |

0.86 |

1.8 |

0.6 |

6.5 |

320 |

3050 |

13000 |

|

Y800-6 |

4000 |

437 |

994 |

96.3 |

0.86 |

1.8 |

0.6 |

6.5 |

385 |

3400 |

13600 |

|

Y800-6 |

4500 |

491 |

994 |

96.4 |

0.86 |

1.8 |

0.6 |

6.5 |

385 |

3400 |

14000 |

|

Y800-6 |

5000 |

548 |

994 |

96.4 |

0.87 |

1.8 |

0.6 |

6.5 |

440 |

3550 |

15000 |

|

Y900-6 |

5600 |

612 |

995 |

96.4 |

0.87 |

1.8 |

0.6 |

6.5 |

490 |

3550 |

16000 |

|

Y900-6 |

6300 |

680 |

995 |

96.5 |

0.87 |

1.8 |

0.6 |

6.5 |

610 |

4150 |

17000 |

|

Y900-6 |

7100 |

770 |

995 |

96.6 |

0.87 |

1.8 |

0.6 |

6.5 |

610 |

4150 |

17500 |

|

Y1000-6 |

8000 |

868 |

996 |

96.7 |

0.87 |

1.8 |

0.6 |

6.5 |

940 |

4150 |

19000 |

|

Y1000-6 |

9000 |

970 |

996 |

96.8 |

0.87 |

1.8 |

0.6 |

6.5 |

1080 |

5000 |

20000 |

|

Y1000-6 |

10000 |

1076 |

996 |

96.9 |

0.87 |

1.8 |

0.6 |

6.5 |

1250 |

6200 |

21000 |

|

Y710-8 |

1800 |

207 |

744 |

95.4 |

0.85 |

1.8 |

0.6 |

6.5 |

230 |

3100 |

11000 |

|

Y710-8 |

2000 |

230 |

774 |

95.5 |

0.85 |

1.8 |

0.6 |

6.5 |

260 |

3200 |

11500 |

|

Y710-8 |

2240 |

254 |

774 |

95.6 |

0.85 |

1.8 |

0.6 |

6.5 |

270 |

3200 |

12000 |

|

Y800-8 |

2500 |

287 |

774 |

95.7 |

0.85 |

1.8 |

0.6 |

6.5 |

500 |

5100 |

13000 |

|

Y800-8 |

2800 |

320 |

774 |

95.8 |

0.85 |

1.8 |

0.6 |

6.5 |

590 |

5400 |

14000 |

|

V800-8 |

3150 |

360 |

774 |

95.8 |

0.85 |

1.8 |

0.6 |

6.5 |

590 |

5400 |

14500 |

|

Y800-8 |

3550 |

404 |

774 |

95.9 |

0.85 |

1.8 |

0.6 |

6.5 |

710 |

5400 |

15500 |

|

Y900-8 |

4000 |

454 |

745 |

96 |

0.86 |

1.8 |

0.6 |

6.5 |

860 |

5400 |

16500 |

|

V900-8 |

4500 |

510 |

745 |

96.1 |

0.86 |

1.8 |

0.6 |

6.5 |

940 |

5800 |

17500 |

|

Y900-8 |

5000 |

565 |

745 |

96.2 |

0.86 |

1.8 |

0.6 |

6.5 |

1040 |

5800 |

18500 |

|

V1000-8 |

5600 |

622 |

746 |

96.2 |

0.86 |

1.8 |

0.6 |

6.5 |

1500 |

5800 |

19500 |

|

Y1000-8 |

6300 |

697 |

746 |

96.3 |

0.86 |

1.8 |

0.6 |

6.5 |

1700 |

6800 |

20500 |

|

V1000-8 |

7100 |

783 |

746 |

96.4 |

0.86 |

1.8 |

0.6 |

6.5 |

1950 |

6800 |

21500 |

|

V1000-8 |

8000 |

884 |

746 |

96.5 |

0.86 |

1.8 |

0.6 |

6.5 |

1950 |

6800 |

22000 |

|

Y710-10 |

1600 |

190 |

594 |

95 |

0.83 |

1.8 |

0.6 |

6 |

345 |

4900 |

10500 |

|

Y710-10 |

1800 |

214 |

594 |

95.1 |

0.83 |

1.8 |

0.6 |

6 |

385 |

5660 |

11000 |

|

Y710-10 |

2000 |

238 |

594 |

95.2 |

0.83 |

1.8 |

0.6 |

6 |

440 |

6800 |

12000 |

|

V800-10 |

2240 |

263 |

595 |

95.3 |

0.83 |

1.8 |

0.6 |

6 |

600 |

7700 |

13500 |

|

Y800-10 |

2500 |

296 |

595 |

95.4 |

0.83 |

1.8 |

0.6 |

6 |

710 |

8600 |

14500 |

|

Y800-10 |

2800 |

330 |

595 |

95.5 |

0.83 |

1.8 |

0.6 |

6 |

710 |

9000 |

15000 |

|

Y900-10 |

3150 |

365 |

596 |

95.6 |

0.84 |

1.8 |

0.6 |

6 |

960 |

10700 |

16000 |

|

Y900-10 |

3550 |

411 |

596 |

95.7 |

0.84 |

1.8 |

0.6 |

6 |

1070 |

10900 |

17000 |

|

Y900-10 |

4000 |

462 |

596 |

95.8 |

0.84 |

1.8 |

0.6 |

6 |

1190 |

10900 |

18500 |

|

Y900-10 |

4500 |

519 |

596 |

95.8 |

0.84 |

1.8 |

0.6 |

6 |

1190 |

10900 |

19000 |

|

Y1000-10 |

5000 |

573 |

597 |

95.9 |

0.84 |

1.8 |

0.6 |

6 |

1570 |

10900 |

21000 |

|

Y1000-10 |

5600 |

639 |

597 |

95.9 |

0.84 |

1.8 |

0.6 |

6 |

1750 |

12300 |

22500 |

|

Y1000-10 |

6300 |

716 |

597 |

96 |

0.84 |

1.8 |

0.6 |

6 |

1950 |

14300 |

23500 |

|

Y1000-10 |

7100 |

809 |

597 |

96 |

0.84 |

1.8 |

0.6 |

6 |

2250 |

16300 |

24500 |

|

Y710-12 |

1120 |

140 |

495 |

94.5 |

0.79 |

1.8 |

0.6 |

6 |

305 |

6400 |

10500 |

|

Y710-12 |

1250 |

155 |

495 |

94.6 |

0.79 |

1.8 |

0.6 |

6 |

340 |

7500 |

11000 |

|

Y710-12 |

1400 |

174 |

495 |

94.7 |

0.79 |

1.8 |

0.6 |

6 |

380 |

8500 |

11500 |

|

Y800-12 |

1600 |

199 |

495 |

94.7 |

0.8 |

1.8 |

0.6 |

6 |

570 |

10500 |

12500 |

|

Y800-12 |

1800 |

224 |

495 |

94.8 |

0.8 |

1.8 |

0.6 |

6 |

670 |

11700 |

13500 |

|

Y800-12 |

2000 |

248 |

495 |

94.9 |

0.8 |

1.8 |

0.6 |

6 |

740 |

11700 |

14500 |

|

Y800-12 |

2240 |

278 |

495 |

95 |

0.8 |

1.8 |

0.6 |

6 |

780 |

11700 |

15500 |

|

Y900-12 |

2500 |

305 |

496 |

95.2 |

0.81 |

1.8 |

0.6 |

6 |

1571 |

11700 |

16500 |

|

Y900-12 |

2800 |

340 |

496 |

95.3 |

0.81 |

1.8 |

0.6 |

6 |

1100 |

12400 |

17500 |

|

Y900-12 |

3150 |

383 |

496 |

95.4 |

0.81 |

1.8 |

0.6 |

6 |

1200 |

13500 |

18500 |

|

Y1000-12 |

3550 |

428 |

497 |

95.5 |

0.81 |

1.8 |

0.6 |

6 |

1640 |

14500 |

20000 |

|

Y1000-12 |

4000 |

480 |

497 |

95.6 |

0.81 |

1.8 |

0.6 |

6 |

1800 |

16200 |

21000 |

|

Y1000-12 |

4500 |

541 |

497 |

95.6 |

0.81 |

1.8 |

0.6 |

6 |

2000 |

18800 |

22500 |

|

Y1000-12 |

5000 |

601 |

497 |

95.7 |

0.81 |

1.8 |

0.6 |

6 |

2300 |

22800 |

24000 |

|

Y710-16 |

630 |

86 |

370 |

93.1 |

0.73 |

1.8 |

0.6 |

6 |

370 |

9500 |

10000 |

|

Y710-16 |

710 |

98 |

370 |

93.3 |

0.73 |

1.8 |

0.6 |

6 |

430 |

15710 |

11000 |

|

Y710-16 |

800 |

110 |

370 |

93.4 |

0.73 |

1.8 |

0.6 |

6 |

520 |

15710 |

11500 |

|

Y710-16 |

900 |

121 |

370 |

93.5 |

0.73 |

1.8 |

0.6 |

6 |

520 |

11000 |

12000 |

|

Y800-16 |

1000 |

134 |

371 |

93.6 |

0.74 |

1.8 |

0.6 |

6 |

620 |

11000 |

12500 |

|

Y800-16 |

1120 |

150 |

371 |

93.7 |

0.74 |

1.8 |

0.6 |

6 |

720 |

12300 |

13500 |

|

Y800-16 |

1250 |

157 |

371 |

93.8 |

0.74 |

1.8 |

0.6 |

6 |

810 |

12300 |

14500 |

|

Y800-16 |

1400 |

187 |

371 |

93.9 |

0.74 |

1.8 |

0.6 |

6 |

810 |

16200 |

15000 |

|

Y900-16 |

1600 |

207 |

371 |

94 |

0.75 |

1.8 |

0.6 |

6 |

1080 |

18600 |

16000 |

|

Y900-16 |

1800 |

232 |

371 |

94.1 |

0.75 |

1.8 |

0.6 |

6 |

1150 |

19500 |

17000 |

|

Y900-16 |

2000 |

257 |

371 |

94.2 |

0.75 |

1.8 |

0.6 |

6 |

1260 |

21100 |

18000 |

|

Y1000-16 |

2240 |

289 |

372 |

94.3 |

0.75 |

1.8 |

0.6 |

6 |

1750 |

20500 |

20000 |

|

Y1000-16 |

2500 |

322 |

372 |

94.4 |

0.75 |

1.8 |

0.6 |

6 |

1900 |

22200 |

21000 |

|

Y1000-16 |

2800 |

360 |

372 |

94.5 |

0.75 |

1.8 |

0.6 |

6 |

2100 |

24800 |

22000 |

Y series medium three-phase asynchronous motor technical data

| Model number

|

Kw |

A |

r/min |

% |

cosθ |

lst ln |

CZPT Mn |

Mmax Mn |

(J)kg.m 2 |

kg |

|

Y450-2 |

220 |

15 |

2981 |

92.85 |

0.915 |

6.85 |

0.65 |

2.58 |

16 |

3150 |

|

Y450-2 |

250 |

17 |

2978 |

92.93 |

0.916 |

6.04 |

0.6 |

2.26 |

18 |

3200 |

|

Y450-2 |

280 |

19 |

2979 |

93.07 |

0.913 |

6.34 |

0.6 |

2.37 |

20 |

3260 |

|

Y450-2 |

315 |

21.2 |

2979 |

93.3 |

0.92 |

6.42 |

0.64 |

2.38 |

22 |

3380 |

|

Y450-2 |

355 |

25.06 |

2980 |

93.8 |

0.872 |

6.83 |

0.67 |

2.57 |

24 |

3400 |

|

Y450-2 |

400 |

28.17 |

2978 |

94.1 |

0.871 |

6.3 |

0.6 |

2.28 |

27 |

3480 |

|

Y450-2 |

450 |

31.56 |

2979 |

94.3 |

0.873 |

6.43 |

0.65 |

2.43 |

30 |

3550 |

|

Y450-2 |

500 |

35.07 |

2976 |

94.4 |

0.872 |

6.4 |

0.6 |

2.21 |

33 |

3620 |

|

Y450-2 |

560 |

39.51 |

2978 |

94.5 |

0.872 |

6.41 |

0.68 |

2.39 |

36 |

3710 |

|

Y450-2 |

630 |

44.15 |

2979 |

94.6 |

0.871 |

6.43 |

0.85 |

2.31 |

39 |

3780 |

|

Y500-2 |

710 |

49.2 |

2978 |

94.7 |

0.88 |

6.26 |

0.85 |

2.23 |

43 |

3870 |

|

Y500-2 |

800 |

53.2 |

2978 |

94.83 |

0.914 |

6.29 |

0.87 |

2.24 |

51 |

3930 |

|

Y500-2 |

900 |

59.5 |

2978 |

95.1 |

0.917 |

6.27 |

0.89 |

2.23 |

55 |

4571 |

|

Y500-2 |

1000 |

66 |

2978 |

95.25 |

0.918 |

6.42 |

0.93 |

2.27 |

57 |

4100 |

|

Y500-2 |

1120 |

74.2 |

2982 |

95.61 |

0.911 |

6.38 |

0.69 |

2.36 |

58 |

4260 |

|

Y560-2 |

1250 |

82.8 |

2982 |

95.73 |

0.911 |

6.59 |

0.73 |

2.43 |

67 |

5400 |

|

Y560-2 |

1400 |

93.2 |

2983 |

95.84 |

0.905 |

6.89 |

0.79 |

2.55 |

73 |

5510 |

|

Y560-2 |

1600 |

106.3 |

2980 |

95.95 |

0.906 |

6.01 |

0.68 |

2.22 |

80 |

5620 |

|

Y630-2 |

1800 |

118 |

2985 |

96.29 |

0.915 |

6.79 |

0.69 |

2.53 |

86 |

9720 |

|

Y630-2 |

2000 |

131 |

2983 |

96.35 |

0.915 |

6.12 |

0.62 |

2.28 |

92 |

9860 |

|

Y630-2 |

2240 |

148.1 |

2984 |

96.5 |

0.905 |

6.71 |

0.7 |

2.51 |

96 |

1571 |

|

Y450-4 |

220 |

15.82 |

1486 |

92.83 |

0.865 |

6.06 |

0.93 |

2.5 |

37.5 |

2890 |

|

Y450-4 |

250 |

17.95 |

1485 |

93.04 |

0.864 |

5.83 |

0.9 |

2.4 |

40 |

2940 |

|

Y450-4 |

280 |

19.87 |

1485 |

93.37 |

0.871 |

5.77 |

0.89 |

2.38 |

40 |

3000 |

|

Y450-4 |

315 |

22.29 |

1484 |

93.57 |

0.872 |

5.67 |

0.89 |

2.34 |

42.5 |

3060 |

|

Y450-4 |

355 |

24.92 |

1484 |

93.84 |

0.872 |

5.59 |

0.88 |

2.31 |

47.5 |

3160 |

|

Y450-4 |

400 |

27.71 |

1480 |

93.82 |

0.888 |

5.69 |

0.88 |

2.42 |

62.5 |

3160 |

|

Y450-4 |

450 |

30.83 |

1479 |

94.04 |

0.896 |

5.62 |

0.88 |

2.38 |

67.5 |

3230 |

|

Y450-4 |

500 |

34.13 |

1479 |

94.21 |

0.898 |

5.72 |

0.91 |

2.42 |

75 |

3330 |

|

Y450-4 |

560 |

3778 |

1480 |

94.55 |

0.905 |

5.82 |

0.94 |

2.47 |

82.5 |

3490 |

|

Y450-4 |

630 |

44.52 |

1487 |

94.47 |

0.865 |

5.98 |

0.89 |

2.24 |

82.5 |

3650 |

|

Y500-4 |

710 |

48.23 |

1486 |

94.68 |

0.898 |

6.02 |

0.89 |

2.44 |

85 |

4330 |

|

Y500-4 |

800 |

53.69 |

1486 |

94.9 |

0.906 |

5.84 |

0.87 |

2.35 |

92.5 |

4530 |

|

Y500-4 |

900 |

59.62 |

1485 |

95.03 |

0.912 |

5.7 |

0.86 |

2.29 |

100 |

4730 |

|

Y500-4 |

1000 |

68.68 |

1489 |

95.32 |

0.882 |

5.85 |

0.84 |

2.24 |

3315 |

5571 |

|

Y500-4 |

1120 |

96.48 |

1489 |

95.43 |

0.886 |

5.71 |

0.85 |

2.16 |

3910 |

5350 |

|

Y560-4 |

1250 |

84.89 |

1489 |

95.52 |

0.89 |

5.96 |

0.9 |

2.25 |

460 |

6410 |

|

Y560-4 |

1400 |

94.87 |

1490 |

95.73 |

0.89 |

6.27 |

0.96 |

2.39 |

547.5 |

6620 |

|

Y560-4 |

1600 |

108.35 |

1491 |

95.8 |

0.89 |

5.88 |

0.85 |

2.24 |

487.5 |

7910 |

|

Y630-4 |

1800 |

117.8 |

1491 |

95.9 |

0.92 |

6.02 |

0.92 |

2.34 |

572.5 |

8340 |

|

Y630-4 |

2000 |

132.18 |

1491 |

96 |

0.91 |

5.12 |

0.91 |

2.31 |

605.5 |

8560 |

|

Y630-4 |

2240 |

147.56 |

1491 |

96.1 |

0.912 |

5.97 |

0.9 |

2.23 |

650.5 |

8670 |

|

Y450-6 |

220 |

16.15 |

991 |

93.04 |

0.845 |

5.65 |

0.94 |

2.32 |

217.5 |

3039 |

|

Y450-6 |

250 |

18.51 |

991 |

93.24 |

0.836 |

5.65 |

0.94 |

2.34 |

217.5 |

3090 |

|

Y450-6 |

280 |

20.43 |

990 |

93.88 |

0.847 |

5.52 |

0.92 |

1.26 |

232.5 |

3180 |

|

Y450-6 |

315 |

23.61 |

990 |

92.8 |

0.83 |

5.41 |

0.91 |

2.22 |

247.5 |

3260 |

|

Y450-6 |

355 |

25.93 |

990 |

93.1 |

0.84 |

5.31 |

0.9 |

2.17 |

267.5 |

3420 |

|

Y450-6 |

400 |

29.26 |

989 |

93.3 |

0.846 |

5.27 |

0.9 |

2.15 |

292.5 |

3470 |

|

Y450-6 |

450 |

33.28 |

992 |

93.5 |

0.835 |

5.45 |

0.85 |

2.12 |

235 |

3650 |

|

Y500-6 |

500 |

36.02 |

992 |

94.38 |

0.849 |

5.53 |

0.88 |

2.18 |

252.5 |

4030 |

|

Y500-6 |

560 |

39.58 |

992 |

94.61 |

0.863 |

5.57 |

0.89 |

2.17 |

285 |

4330 |

|

Y500-6 |

630 |

44.75 |

993 |

94.8 |

0.857 |

5.71 |

0.93 |

2.24 |

317.5 |

4530 |

|

Y500-6 |

710 |

50.87 |

991 |

94.8 |

0.85 |

5.64 |

0.92 |

2.22 |

932.5 |

4780 |

|

Y500-6 |

800 |

57.19 |

991 |

94.9 |

0.851 |

5.61 |

0.93 |

2.21 |

1047.5 |

5120 |

|

Y560-6 |

900 |

62.41 |

991 |

95.39 |

0.873 |

5.65 |

0.95 |

2.22 |

1137.5 |

6300 |

|

Y560-6 |

1000 |

69.13 |

991 |

95.5 |

0.874 |

5.75 |

0.98 |

2.25 |

1280 |

6570 |

|

Y560-6 |

1120 |

78.75 |

993 |

95.48 |

0.86 |

5.56 |

0.83 |

1.95 |

1232.5 |

6880 |

|

Y560-6 |

1250 |

86.77 |

993 |

95.6 |

0.87 |

5.68 |

0.87 |

2.02 |

1387.5 |

7180 |

|

Y630-6 |

1400 |

98.76 |

994 |

95.97 |

0.862 |

5.92 |

0.93 |

2.28 |

1592.5 |

7990 |

|

Y630-6 |

1600 |

112.8 |

994 |

95.98 |

0.865 |

5.94 |

0.94 |

2.28 |

1792.5 |

8370 |

|

Y630-6 |

1800 |

127.44 |

994 |

95.6 |

0.863 |

5.97 |

0.96 |

2.28 |

2012.5 |

8750 |

|

Y450-8 |

220 |

17.7 |

744 |

93.2 |

0.77 |

5.3 |

0.91 |

2.24 |

777.5 |

3070 |

|

Y450-8 |

250 |

19.93 |

744 |

93.42 |

0.775 |

5.09 |

0.87 |

2.14 |

805 |

3210 |

|

Y500-8 |

280 |

21.73 |

744 |

93.7 |

0.794 |

5.17 |

0.9 |

2.09 |

730 |

3750 |

|

Y500-8 |

315 |

24.46 |

744 |

93.85 |

0.792 |

5.06 |

0.88 |

2.05 |

765 |

3800 |

|

Y500-8 |

355 |

27.43 |

744 |

94.13 |

0.795 |

4.98 |

0.87 |

2.02 |

795 |

3910 |

|

Y500-8 |

400 |

31 |

744 |

94.22 |

0.791 |

4.93 |

0.87 |

2 |

835 |

4100 |

|

Y500-8 |

450 |

34.61 |

744 |

94.38 |

0.795 |

4.88 |

0.86 |

1.97 |

930 |

4300 |

|

Y500-8 |

500 |

38.57 |

744 |

94.6 |

0.791 |

4.99 |

0.86 |

2.03 |

1012.5 |

4450 |

|

Y500-8 |

560 |

40.06 |

744 |

94.8 |

0.792 |

5.82 |

0.8 |

1.86 |

1052 |

4680 |

|

Y560-8 |

630 |

45.85 |

745 |

94.91 |

0.841 |

5.17 |

0.81 |

2 |

1910 |

5850 |

|

Y560-8 |

710 |

51.79 |

745 |

94.98 |

0.833 |

5.18 |

0.81 |

2.1 |

2127.5 |

5930 |

|

Y560-8 |

800 |

58.33 |

745 |

95.09 |

0.833 |

5.13 |

0.81 |

1.99 |

2407.5 |

6100 |

|

Y560-8 |

900 |

65.83 |

746 |

95.1 |

0.83 |

5.5 |

0.82 |

2.09 |

2215 |

6350 |

|

Y630-8 |

1000 |

72.71 |

746 |

95.1 |

0.835 |

5.55 |

0.84 |

2.1 |

2502.5 |

7630 |

|

Y630-8 |

1120 |

80.76 |

746 |

95.32 |

0.64 |

5.53 |

0.85 |

2.06 |

2982.5 |

8571 |

|

Y630-8 |

1250 |

89.75 |

747 |

95.5 |

0.842 |

5.72 |

0.88 |

2.15 |

3787.5 |

8330 |

|

Y500-10 |

220 |

18.15 |

594 |

92.55 |

0.75 |

5.24 |

0.9 |

2.45 |

877.5 |

3700 |

|

Y500-10 |

250 |

20.74 |

594 |

92.69 |

0.751 |

5.04 |

0.87 |

2.35 |

910 |

3750 |

|

Y500-10 |

280 |

23.34 |

594 |

92.86 |

0.746 |

4.99 |

0.86 |

2.35 |

937.5 |

3850 |

|

Y500-10 |

315 |

25.87 |

593 |

92.98 |

0.756 |

4.9 |

0.85 |

2.27 |

1015 |

3950 |

|

Y500-10 |

355 |

28.57 |

593 |

93.31 |

0.769 |

4.93 |

0.88 |

2.26 |

1150 |

4250 |

|

Y500-10 |

400 |

32.01 |

593 |

93.61 |

0.771 |

4.93 |

0.87 |

2.24 |

1225 |

4400 |

|

Y560-10 |

450 |

35.93 |

593 |

93.67 |

0.772 |

4.98 |

0.89 |

2.28 |

1352.5 |

4530 |

|

Y560-10 |

500 |

38.71 |

596 |

93.87 |

0.794 |

5.18 |

0.86 |

2.05 |

2542.5 |

5840 |

|

Y560-10 |

560 |

43.15 |

596 |

94.04 |

0.797 |

5.11 |

0.85 |

2.02 |

2897.5 |

6000 |

|

Y560-10 |

630 |

48.85 |

596 |

94.19 |

0.791 |

5.1 |

0.86 |

2.03 |

3270 |

6150 |

|

Y560-10 |

710 |

54.57 |

596 |

94.33 |

0.796 |

5.07 |

0.86 |

2 |

3642.5 |

6410 |

|

Y630-10 |

800 |

59.79 |

596 |

94.75 |

0.815 |

5.35 |

0.81 |

2.14 |

2510 |

7490 |

|

Y630-10 |

900 |

66.37 |

596 |

94.92 |

0.825 |

5.36 |

0.82 |

2.12 |

2842.5 |

7840 |

|

Y630-10 |

1000 |

74.09 |

597 |

94.99 |

0.82 |

5.57 |

0.82 |

2.21 |

3310 |

8160 |

|

Y630-10 |

1120 |

83.21 |

597 |

95.17 |

0.817 |

5.78 |

0.86 |

2.3 |

4315 |

8600 |

|

Y500-12 |

220 |

18.96 |

495 |

91.83 |

0.729 |

4.76 |

0.87 |

2.13 |

1350 |

3900 |

|

Y500-12 |

250 |

21.45 |

495 |

92.37 |

0.729 |

4.62 |

0.84 |

2.07 |

1722.5 |

4100 |

|

Y500-12 |

280 |

23.33 |

495 |

92.64 |

0.748 |

4.56 |

0.83 |

2 |

1870 |

4350 |

|

Y560-12 |

315 |

26.18 |

495 |

92.97 |

0.747 |

4.51 |

0.81 |

2.02 |

2503 |

5580 |

|

Y560-12 |

355 |

28.57 |

496 |

92.91 |

0.772 |

5.25 |

0.93 |

2.17 |

2582.5 |

5660 |

|

Y560-12 |

400 |

32.21 |

496 |

92.91 |

0.772 |

5.17 |

0.93 |

2.13 |

2622.5 |

5740 |

|

Y560-12 |

450 |

35.97 |

496 |

93.22 |

0.775 |

5.05 |

0.9 |

2.07 |

3085 |

5900 |

|

Y560-12 |

500 |

40.01 |

496 |

93.36 |

0.773 |

5.01 |

0.89 |

2.06 |

3482.5 |

6070 |

|

Y630-12 |

560 |

45.55 |

496 |

94.01 |

0.755 |

4.82 |

0.85 |

1.97 |

4250 |

7420 |

|

Y630-12 |

630 |

51.17 |

496 |

94.17 |

0.755 |

4.79 |

0.85 |

1.96 |

4780 |

7620 |

|

Y630-12 |

710 |

57.31 |

496 |

94.33 |

0.758 |

4.75 |

0.84 |

1.93 |

5480 |

7900 |

|

Y630-12 |

800 |

63.75 |

496 |

94.47 |

0.767 |

4.75 |

0.85 |

1.91 |

6140 |

8290 |

Company Profile

The company is mainly engaged in the research and development, manufacturing and service of large and medium-sized motors, small and medium-sized generators, special and servo motors, new energy equipment motors and motor maintenance and remanufacturing industry, based on providing customers with motor system solutions. With an annual comprehensive production capacity of 6 million kilowatts, the products are widely used in power, water conservancy, building materials, metallurgy, mining, petrochemical, urban infrastructure construction, weapons and equipment, etc. The products enjoy a good reputation throughout the country and are exported to 26 countries and regions on 5 continents.

Y motor is widely used in machine tools, fans, pumps, compressors and transportation, agriculture, food processing and other kinds of mechanical power transmission.

Conditions of use

Under the following conditions, the Y3 motor should be CZPT to operate normally:

1, the altitude does not exceed 1000m

2, the ambient air temperature varies with the season, but does not exceed 40°C

3, the ambient air temperature is -15°C

4, the average relative humidity of the wet month is 90%, and the average temperature of the month is not higher than 25ºC;

The working principle

When the three-phase stator winding of the motor (each with a difference of 120 degrees electrical Angle) is passed into the three-phase symmetrical alternating current, a rotating magnetic field will be generated. The rotating magnetic field cuts the rotor winding, thus generating induced current in the rotor winding (the rotor winding is a closed path). The current-carrying rotor conductor will generate electromagnetic force under the action of the stator rotating magnetic field. Thus, electromagnetic torque is formed on the motor rotating shaft, driving the motor to rotate, and the direction of the motor rotation is the same as the direction of the rotating magnetic field. The rotor speed of the three-phase asynchronous motor is lower than that of the rotating magnetic field, and the rotor winding is induced by the relative motion between the magnetic field and the electromotive force and current, and the electromagnetic torque is generated by the interaction with the magnetic field to achieve energy conversion. Compared with single-phase asynchronous motor, three-phase asynchronous motor has good operation performance and can save various materials. According to the different rotor structure, the three-phase asynchronous motor can be divided into 2 types: cage type and winding type. The cage rotor asynchronous motor is simple in structure, reliable in operation, light in weight and cheap in price, and has been widely used. The rotor and stator of the winding three-phase asynchronous motor are also equipped with three-phase winding and connected to the external rheostat by slip ring and brush. Adjusting rheostat resistance can improve motor starting performance and adjust motor speed.

Widely used in pump, fan, textile machinery, construction machinery and other transmission machinery industry.

Case reference

Mechanical equipment industry solutions

The company’s products cover the whole industrial chain from nuclear power, gas power generation, thermal power, hydropower, wind power, to waste heat power generation to form a complete product chain including soft start, motor, frequency conversion control, transformer, power supply, system energy saving and service. In the national nuclear power technology, offshore drilling platform, clean energy and other application fields for the country’s power industry construction to provide our more advanced, reliable, energy-saving product solutions.

Reducer industry solutions

The products cover the whole industrial chain from nuclear power, gas power generation, thermal power, hydropower, wind power, to waste heat power generation to form a complete product chain including soft start, motor, frequency conversion control, transformer, power supply, system energy saving and service. In the national nuclear power technology, offshore drilling platform, clean energy and other application fields for the country’s power industry construction to provide our more advanced, reliable, energy-saving product solutions.

Packaging & Shipping

1.FedEX / DHL / UPS / TNT for samples,Door to door service;

2.By sea for batch goods;

3.Customs specifying freight forwarders or negotiable shipping methods;

4.Delivery Time:20-25 Days for samples;30-35 Days for batch goods;

5.Payment Terms:T/T,L/C at sight,D/P etc.

FAQ

Q1. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry.

If you are urgent to get the price, please send the message on and or call us directly.

Q2. How can I get a sample to check your quality?

After price confirmed, you can requiry for samples to check quality.

If you need the samples, we will charge for the sample cost.

But the sample cost can be refundable when your quantity of first order is above the MOQ

Q3. Can you do OEM for us?

Yes, the product packing can be designed as you want.

Q4. How about MOQ?

1 pcs for carton box.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial, Universal, Household Appliances, Power Tools |

|---|---|

| Operating Speed: | High Speed |

| Number of Stator: | Three-Phase |

| Samples: |

US$ 2500/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

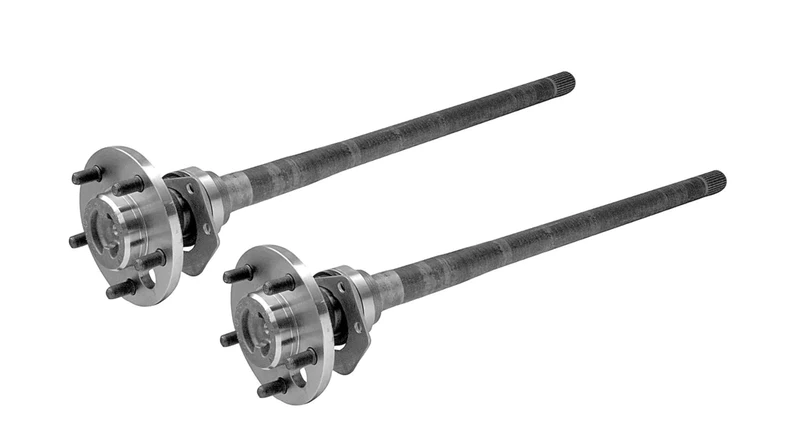

What are the eco-friendly or sustainable aspects of axle shaft production?

Axle shaft production can incorporate several eco-friendly or sustainable practices that aim to minimize environmental impact and promote sustainability throughout the manufacturing process. Here’s a detailed explanation of the eco-friendly and sustainable aspects of axle shaft production:

- Material Selection: One of the primary considerations for eco-friendly axle shaft production is the selection of materials. Opting for sustainable materials, such as recycled steel or lightweight alloys, reduces the environmental footprint associated with raw material extraction and processing. Using recycled materials helps conserve natural resources and reduces energy consumption and greenhouse gas emissions compared to using virgin materials.

- Energy Efficiency: Promoting energy efficiency in axle shaft production is another eco-friendly aspect. Implementing energy-saving technologies, such as efficient manufacturing processes, optimized equipment, and smart controls, helps minimize energy consumption during production. Utilizing renewable energy sources, such as solar or wind power, further reduces greenhouse gas emissions and reliance on fossil fuels.

- Waste Reduction and Recycling: Axle shaft production can incorporate waste reduction and recycling practices to minimize the amount of waste generated and promote a circular economy. Implementing measures like effective waste management systems, recycling programs, and responsible disposal of hazardous materials ensures that waste is minimized, and valuable resources are recovered and reused whenever possible.

- Water Conservation: Sustainable axle shaft production also includes measures to conserve water resources. Implementing water-efficient technologies, recycling and treating water used in manufacturing processes, and implementing water management strategies help minimize water consumption and reduce the strain on freshwater resources.

- Emissions Reduction: Axle shaft production can focus on reducing emissions to minimize its environmental impact. Implementing emission control technologies, such as installing pollution control devices or adopting cleaner manufacturing processes, helps reduce air pollutants released during production. Additionally, monitoring and optimizing transportation logistics can help minimize carbon emissions associated with the transportation of raw materials and finished axle shafts.

- Life Cycle Assessment: Conducting a life cycle assessment (LCA) of axle shaft production allows for a comprehensive evaluation of the environmental impact at each stage, from raw material extraction to end-of-life disposal. LCA helps identify areas where improvements can be made, enabling manufacturers to make informed decisions and implement sustainable practices throughout the entire life cycle of the axle shafts.

- Supply Chain Sustainability: Promoting sustainability in axle shaft production involves considering the sustainability practices of suppliers and fostering sustainable partnerships throughout the supply chain. Encouraging suppliers to adhere to environmental standards, promoting responsible sourcing of raw materials, and ensuring ethical labor practices contribute to a more sustainable overall production process.

It’s important to note that specific eco-friendly and sustainable practices may vary among manufacturers and depend on factors such as the size of the production facility, available resources, and technological advancements. However, by incorporating these practices, axle shaft production can reduce its environmental impact, conserve resources, minimize waste, and contribute to a more sustainable automotive industry.

In summary, the eco-friendly and sustainable aspects of axle shaft production include material selection using recycled or sustainable materials, energy efficiency measures, waste reduction and recycling practices, water conservation efforts, emissions reduction strategies, life cycle assessment, and promoting supply chain sustainability. By adopting these practices, axle shaft manufacturers can contribute to a greener and more sustainable future.

Can you describe the maintenance and repair considerations for axle shafts?

Maintenance and repair of axle shafts are essential to ensure the proper functioning and longevity of a vehicle’s drivetrain. Regular maintenance and timely repairs can help prevent costly damages and maintain optimal performance. Here’s a detailed explanation of the maintenance and repair considerations for axle shafts:

Maintenance Considerations:

To keep the axle shafts in good condition, the following maintenance practices are recommended:

- Inspections: Regularly inspect the axle shafts for signs of damage, such as cracks, bends, or excessive wear. Inspect the CV joints, bearings, seals, and retaining devices for leaks, deterioration, or looseness. Pay attention to any unusual noises, vibrations, or fluid leaks that may indicate potential issues.

- Lubrication: Ensure proper lubrication of the axle shafts, CV joints, and bearings as recommended by the vehicle manufacturer. Lubrication helps reduce friction, prevent excessive wear, and extend the lifespan of the components. Check the lubricant levels and quality during routine maintenance and top up or replace the lubricant as needed.

- Seal Protection: Inspect the seals around the axle shafts for damage or leaks. Damaged seals can allow contaminants, such as dirt, moisture, and debris, to enter the axle assembly, leading to premature wear and potential failure of the components. Replace damaged seals promptly to maintain proper protection.

- Boot Inspection: If the axle shafts have constant velocity (CV) joints, inspect the protective boots regularly. The boots cover the CV joints and keep them protected and lubricated. Look for any signs of cracks, tears, or leaking grease. Damaged boots should be replaced promptly to prevent dirt and moisture from entering the CV joints.

- Wheel Bearing Maintenance: If the axle shafts incorporate wheel bearings, follow the manufacturer’s recommendations for bearing maintenance. This may include periodic inspection, cleaning, re-greasing, or replacement of the wheel bearings to ensure smooth rotation and prevent excessive wear.

Repair Considerations:

If axle shaft issues are identified through inspections or during routine maintenance, the following repair considerations should be taken into account:

- Evaluation and Diagnosis: When encountering axle shaft problems, it’s important to accurately diagnose the issue before proceeding with repairs. This may involve a visual inspection, listening for abnormal noises, performing tests, or seeking professional assistance to identify the specific cause of the problem.

- Component Replacement: Depending on the nature and severity of the issue, repair options may vary. In some cases, replacing individual components such as CV joints, bearings, or seals may be sufficient. However, if the axle shaft itself is damaged or worn beyond repair, it may be necessary to replace the entire axle shaft assembly.

- Professional Expertise: Axle shaft repairs can be complex and require specialized knowledge and tools. It is often recommended to seek the assistance of a qualified mechanic or technician who has experience working with axle shafts. They can provide proper diagnosis, perform repairs accurately, and ensure the correct installation of components.

- Quality Parts: When replacing axle shaft components or the entire assembly, it is crucial to use high-quality parts that meet or exceed the manufacturer’s specifications. Using genuine or reputable aftermarket parts can help ensure proper fit, performance, and durability.

- Alignment and Calibration: After axle shaft repairs or replacements, it may be necessary to perform wheel alignment and calibration procedures to ensure proper suspension geometry, wheel balance, and drivetrain synchronization. This helps maintain vehicle stability, tire wear, and overall performance.

By following these maintenance practices and considering the appropriate repair steps, owners can help keep axle shafts in optimal condition, minimize the risk of failure, and ensure the reliable operation of the vehicle’s drivetrain.

Can you explain the different types of axle shafts used in automobiles?

Automobiles utilize different types of axle shafts depending on the vehicle’s drivetrain configuration, suspension design, and intended use. Here are some of the commonly used axle shaft types:

1. Solid Axle Shaft:

A solid axle shaft, also known as a full-floating axle, is a single, rigid shaft that connects the differential to the wheels. It is commonly used in rear-wheel-drive vehicles, trucks, and off-road vehicles. Solid axle shafts provide robustness and strength, making them suitable for heavy-duty applications. They are capable of handling high torque loads and are relatively simple in design. However, solid axle shafts can contribute to a harsher ride and increased unsprung weight compared to other axle types.

2. Split Axle Shaft:

A split axle shaft, also referred to as a semi-floating axle, consists of two separate shafts that connect the differential to each wheel independently. Split axle shafts are commonly used in light-duty passenger vehicles and some rear-wheel-drive trucks. Each shaft supports the weight of its corresponding wheel and transmits torque. Split axle shafts offer a balance between strength and weight savings compared to solid axle shafts. However, they are generally not as robust as full-floating axles and may have lower load-carrying capacity.

3. Half Shaft:

A half shaft, also known as a drive shaft or CV axle, is commonly used in front-wheel-drive and all-wheel-drive vehicles. It connects the differential or transaxle to the front wheels, allowing power transmission and wheel rotation. Half shafts are typically equipped with constant velocity (CV) joints, which accommodate the articulation and angle changes during suspension movement and steering. CV joints enable smooth power transfer and minimize vibrations. Half shafts are usually lighter and more compact than solid or split axle shafts and are designed to handle the demands of front-wheel-drive systems.

4. Torque Tube Axle:

A torque tube axle is an older design that was used in some early automobiles. It consists of a single tube that encases the driveshaft and connects the differential to the wheels. The torque tube axle provides power transmission and support for the wheels but lacks independent suspension. This design has largely been phased out in modern vehicles, as it limits suspension flexibility and can contribute to a harsher ride quality.

5. Independent Rear Suspension Axle Shafts:

In vehicles with independent rear suspension (IRS), each wheel typically has its own axle shaft. These axle shafts connect the differential to the individual wheels and allow independent movement and suspension articulation. Independent rear suspension axle shafts are commonly found in modern passenger cars and some high-performance vehicles. They provide improved handling, ride comfort, and traction compared to solid axle shafts. The design and construction of these axle shafts may vary depending on the specific IRS system implemented in the vehicle.

It’s important to note that the specific axle shaft types used in automobiles can vary depending on the vehicle manufacturer, model, and drivetrain configuration. Additionally, advancements in technology and the increasing popularity of electric vehicles may introduce new axle shaft designs and materials in the future.

In summary, the different types of axle shafts used in automobiles include solid axle shafts, split axle shafts, half shafts, torque tube axles (less common in modern vehicles), and independent rear suspension axle shafts. Each type has its own advantages and is tailored to specific vehicle applications and requirements.

editor by CX 2024-03-18