Product Description

Product Description

Manufacturer Auto Spare Parts Car Suspension parts Electrical parts Body parts Engine parts and Accessories for CZPT Vios Yaris Corolla Fortuner Hilux Crown Hiace LandCruiser Coster 4Runner Highlander Camry etc.

Specification:

Suspension System Parts

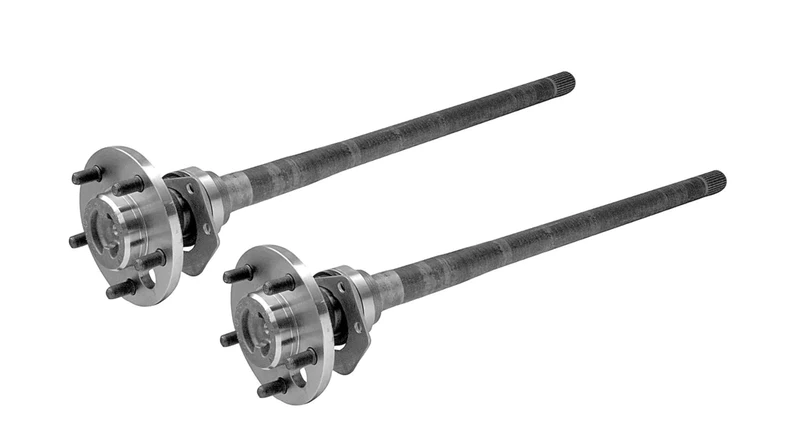

| Description | Rear Axle Shaft For CZPT FJ Criuser Landcruiser Prado 4Runner TRJ150 |

| OEM Number | 42311-65711 42311-65710 |

| For Car Model | For Toyota |

| Delivery Time | 1. 5-7days With Stock 2. 25-40days Mass Production |

| Payment | T/T , Western Union , Paypal , L/C , Cash |

| Shippment | DHL, Fedex,TNT,UPS, By Sea, By Air. |

| Warranty | 12 Months |

| Certificate | ISO9001,TS16949 |

| Package | Standard |

please:

If you are unsure about this part fitting your vehicle then please send us your vehicle reg or full chassis number so we can check and be sure before purchasing.

feel free to contact us to get more information about the products or the price.

Welcome to Consult.

FAQ:

1.Where is your company? Which parts do you mainly sell?

Q:Our company is located in HangZhou,ZheJiang Province,Specilized in CZPT parts

2.How many kinds of products do you have?

A: We have more than 10000+ products for Engine/Suspension/Electrical/Body parts and accessories.

3.What’s the Warranty?

A:Mainly 12 months.

4.What’s the MOQ?

A:The MOQ corresponding to each product and it can be consulted.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Warranty: | 12 Months |

| Material: | Stainless Steel |

| Certification: | ISO/TS16949, ISO9001 |

| Car Make: | Toyota |

| Position: | Front |

| Samples: |

US$ 65/Piece

1 Piece(Min.Order) | |

|---|

What innovations or advancements have been made in axle shaft technology?

Axle shaft technology has witnessed several innovations and advancements over the years, aimed at improving performance, durability, and efficiency. These advancements have been driven by the need to meet evolving vehicle requirements, enhance safety, and reduce environmental impact. Here’s a detailed explanation of some notable innovations in axle shaft technology:

- High-Strength Materials: The development and utilization of high-strength materials have significantly improved the strength and durability of axle shafts. Advanced steel alloys, such as alloy steels, have been engineered to provide superior strength while reducing weight. This allows for increased load-bearing capacity, improved resistance to bending and torsional forces, and enhanced overall performance.

- Composite Axle Shafts: Composite materials, including carbon fiber reinforced polymers (CFRP), have been introduced in axle shaft technology. These materials offer exceptional strength-to-weight ratios, allowing for significant weight reduction while maintaining or even enhancing strength characteristics. Composite axle shafts can contribute to improved fuel efficiency, handling, and performance.

- Advanced Manufacturing Techniques: Innovations in manufacturing techniques have played a vital role in axle shaft technology. Precision machining, forging, and advanced casting methods allow for the production of axle shafts with complex geometries, enhanced surface finishes, and optimized material distribution. These techniques enable the creation of stronger and more efficient axle shafts that can withstand higher loads and provide improved performance.

- Improved Lubrication Systems: Lubrication systems have undergone advancements to ensure optimal performance and longevity of axle shafts. The development of advanced lubricants and improved sealing technologies helps maintain proper lubrication, reducing friction and wear between moving parts. Enhanced lubrication systems contribute to increased efficiency, reduced maintenance requirements, and extended lifespan of axle shafts.

- Electronic Differential Systems: Electronic differential systems, such as electronic limited-slip differentials (eLSD) and torque vectoring systems, have revolutionized axle shaft technology. These systems use sensors, actuators, and electronic control units to distribute torque between the wheels more effectively. By actively managing power delivery, electronic differential systems improve traction, stability, and handling, particularly in challenging driving conditions.

- Integration with Vehicle Dynamics Systems: Axle shaft technology has evolved to integrate with advanced vehicle dynamics control systems. This integration enables seamless coordination between the axle shafts, anti-lock braking systems (ABS), stability control systems, and other safety features. By working in tandem, these systems optimize traction, stability, and overall vehicle performance, enhancing safety and driver confidence.

These innovations and advancements in axle shaft technology have led to significant improvements in performance, strength, efficiency, and safety. High-strength materials, composite axle shafts, advanced manufacturing techniques, improved lubrication systems, electronic differential systems, and integration with vehicle dynamics systems have all contributed to enhanced functionality and durability of axle shafts.

In summary, axle shaft technology has seen notable advancements in recent years. These include the use of high-strength materials, the introduction of composite axle shafts, advancements in manufacturing techniques, improved lubrication systems, the implementation of electronic differential systems, and integration with vehicle dynamics systems. These innovations aim to enhance performance, durability, efficiency, and safety in axle shaft applications, meeting the evolving needs of modern vehicles.

What is the role of axle shafts in the functionality and safety of a vehicle?

The axle shafts play a crucial role in the functionality and safety of a vehicle’s drivetrain. These components are responsible for transmitting torque from the differential or transaxle to the wheels, enabling power delivery and facilitating smooth vehicle operation. Here’s a detailed explanation of the role of axle shafts in the functionality and safety of a vehicle:

Power Transmission:

The primary function of axle shafts is to transfer rotational power from the engine to the wheels. When the engine generates torque, it travels through the transmission system and reaches the differential or transaxle. From there, the axle shafts transmit the torque to the individual wheels, allowing them to rotate and propel the vehicle forward or backward. Axle shafts ensure efficient power transmission, enabling the vehicle to accelerate, maintain speed, and climb inclines effectively.

Wheel Connectivity:

Axle shafts serve as the physical link between the wheels and the drivetrain. They connect the wheels to the differential or transaxle, ensuring that the rotational force generated by the engine is effectively transferred to each wheel. This connectivity enables synchronized wheel movement and coordination, ensuring stable handling, traction, and control of the vehicle.

Suspension Support:

Axle shafts also provide support to the vehicle’s suspension system. They are part of the suspension geometry and assist in maintaining proper wheel alignment and positioning. Axle shafts help bear the weight of the vehicle and absorb various forces and vibrations encountered while driving, contributing to a smoother and more comfortable ride. Additionally, they assist in managing weight transfer during acceleration, braking, and cornering, enhancing stability and handling characteristics.

Drivetrain Safety:

Axle shafts contribute to the safety of the vehicle’s drivetrain in several ways:

- Wheel Power Distribution: By transmitting torque to each wheel, axle shafts ensure balanced power distribution. This helps prevent excessive wheel spin or loss of traction, improving overall stability and control, especially in challenging driving conditions such as slippery surfaces or uneven terrain.

- Steering Control: Axle shafts play a role in the vehicle’s steering system, especially in vehicles with front-wheel drive or all-wheel drive configurations. They assist in transferring the rotational force to the front wheels, allowing for precise steering control and responsiveness.

- Braking Performance: Axle shafts contribute to the effectiveness of the braking system. As the wheels decelerate during braking, the rotational force is transmitted through the axle shafts to the differential or transaxle, facilitating proper distribution of braking force to all wheels. This helps maintain stability, prevent skidding, and ensure efficient braking performance.

Overall Vehicle Safety:

Proper functionality of axle shafts isessential for the overall safety of the vehicle:

- Preventing Catastrophic Failures: Well-maintained and properly functioning axle shafts reduce the risk of catastrophic failures that can lead to loss of control or accidents. Regular inspections and timely repairs or replacements help ensure that the axle shafts are in good condition and can withstand the forces and stresses encountered during normal driving.

- Enhancing Stability and Handling: Axle shafts contribute to the stability and handling characteristics of the vehicle. By facilitating proper power transmission and wheel connectivity, they help maintain traction, prevent wheel slippage, and improve overall vehicle control during various driving maneuvers.

- Supporting Suspension Components: Axle shafts provide support to other suspension components, such as control arms, struts, and springs. In doing so, they assist in maintaining proper suspension geometry, which is critical for safe and predictable handling. A well-functioning suspension system helps absorb shocks, maintain tire contact with the road, and provide a comfortable ride.

- Contributing to Braking Efficiency: The proper functioning of axle shafts ensures effective distribution of braking force to all wheels, enhancing the vehicle’s braking performance and reducing stopping distances. This contributes to overall safety by allowing the driver to maintain control and respond to emergency situations more effectively.

Overall, axle shafts play a vital role in the functionality and safety of a vehicle. They enable power transmission, connect the wheels to the drivetrain, support the suspension system, and contribute to stable handling, traction, and braking performance. Regular maintenance, inspections, and prompt repairs or replacements are essential to ensure the proper functioning of axle shafts and maintain the safety of the vehicle’s drivetrain.

Can you explain the different types of axle shafts used in automobiles?

Automobiles utilize different types of axle shafts depending on the vehicle’s drivetrain configuration, suspension design, and intended use. Here are some of the commonly used axle shaft types:

1. Solid Axle Shaft:

A solid axle shaft, also known as a full-floating axle, is a single, rigid shaft that connects the differential to the wheels. It is commonly used in rear-wheel-drive vehicles, trucks, and off-road vehicles. Solid axle shafts provide robustness and strength, making them suitable for heavy-duty applications. They are capable of handling high torque loads and are relatively simple in design. However, solid axle shafts can contribute to a harsher ride and increased unsprung weight compared to other axle types.

2. Split Axle Shaft:

A split axle shaft, also referred to as a semi-floating axle, consists of two separate shafts that connect the differential to each wheel independently. Split axle shafts are commonly used in light-duty passenger vehicles and some rear-wheel-drive trucks. Each shaft supports the weight of its corresponding wheel and transmits torque. Split axle shafts offer a balance between strength and weight savings compared to solid axle shafts. However, they are generally not as robust as full-floating axles and may have lower load-carrying capacity.

3. Half Shaft:

A half shaft, also known as a drive shaft or CV axle, is commonly used in front-wheel-drive and all-wheel-drive vehicles. It connects the differential or transaxle to the front wheels, allowing power transmission and wheel rotation. Half shafts are typically equipped with constant velocity (CV) joints, which accommodate the articulation and angle changes during suspension movement and steering. CV joints enable smooth power transfer and minimize vibrations. Half shafts are usually lighter and more compact than solid or split axle shafts and are designed to handle the demands of front-wheel-drive systems.

4. Torque Tube Axle:

A torque tube axle is an older design that was used in some early automobiles. It consists of a single tube that encases the driveshaft and connects the differential to the wheels. The torque tube axle provides power transmission and support for the wheels but lacks independent suspension. This design has largely been phased out in modern vehicles, as it limits suspension flexibility and can contribute to a harsher ride quality.

5. Independent Rear Suspension Axle Shafts:

In vehicles with independent rear suspension (IRS), each wheel typically has its own axle shaft. These axle shafts connect the differential to the individual wheels and allow independent movement and suspension articulation. Independent rear suspension axle shafts are commonly found in modern passenger cars and some high-performance vehicles. They provide improved handling, ride comfort, and traction compared to solid axle shafts. The design and construction of these axle shafts may vary depending on the specific IRS system implemented in the vehicle.

It’s important to note that the specific axle shaft types used in automobiles can vary depending on the vehicle manufacturer, model, and drivetrain configuration. Additionally, advancements in technology and the increasing popularity of electric vehicles may introduce new axle shaft designs and materials in the future.

In summary, the different types of axle shafts used in automobiles include solid axle shafts, split axle shafts, half shafts, torque tube axles (less common in modern vehicles), and independent rear suspension axle shafts. Each type has its own advantages and is tailored to specific vehicle applications and requirements.

editor by CX 2024-02-21