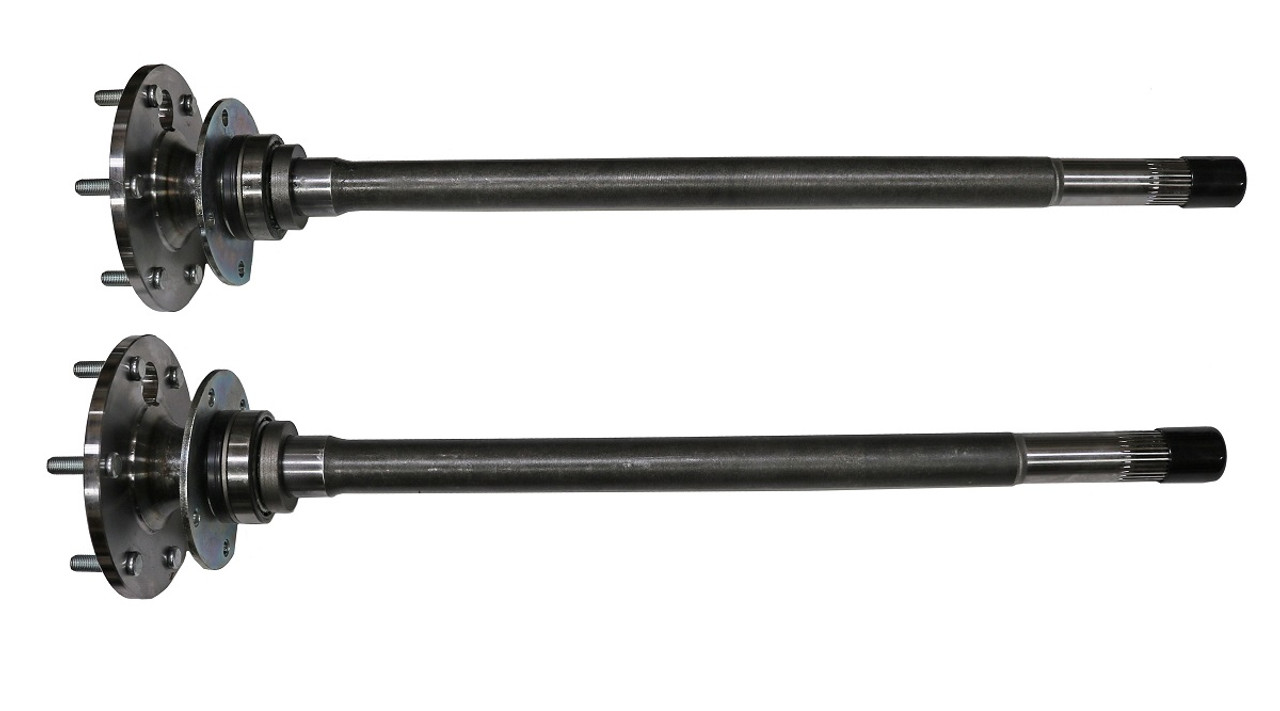

Product Description

ABOUT US

HangZhou Suijin machinery Technology Co,.Ltd is a profational manufacturer in HangZhou city, our main process is investment casting/precision casting and machining, for casting process, we have 2 kinds of production line, 1 is precision casting, another is water glass with competitive cost.

Apart from the investment casting workshop and machine workshop, we also provide the sand casting parts to meet the requirement for varial demand from our customer.

CERTIFICATIONS

Our company got the ISO9001 and IATF16949 certification, and aslo we are awarded the new high-tech enterprice by Chinese government, and we have more than 20 patent.

ADVANTAGES

• More than 10 years experience on casting and machining

• Advanced inspection equipment to ensure the tolerance

• Flexible PO QTY to meet customer demand

• Professional engineers in casting and machining

• Competitive price and exllent parts quality

• Nearby HangZhou port, on-time delivery

PROCESS FLOW

OEM&ODM SERVICE

HangZhou suijin machinery technology can provide the ODM&OEM service for customer, and main is ODM, we can manufacturing the customized parts according to 2D&3D, we have professional R&D team can take part in ealier development phase of the project.

AVALIABLE MATERIA & SURFACE TREATMENT

| Avaliable Material | |||

| Carbon Steel | Alloy Steel | High Chromium Cast Iron | Low carbon steel |

| Stainless Steel | Duplex Stainless Steel | Steel bar | Ductile Cast Iron |

| Surface treatment | |||

| Heat Treatment | Zinc Coating | Blackening | Mirror Polishing |

| Satin Polishing | Electrolytic Polishing | Shot Peening | DACROMET |

PRODUCT APPLICATION

AUTO PARTS

• Exhaust inlet/outlet cone • Shift sleeve • Fuel rail bracket

• Tempreture sensor boss • Mounting Brackets • Oxygen sensor boss

• Brake balance block • EGR sensor boss • Exhaust valve body

ARCHITECTURAL HARDWARE

• Mounting Base • Mounting plate • Bearing Covers

• Coupling • Grount sleeve • Sprockets

• Handle • law glass curtain wall accessories • Side Plates

AGRICULTURAL MACHINERY PARTS

• Tooth Blocks • Track shoes • Bucket Teeth

• Track Links • Clamping • Mounting Brackets

• Lifting Eyes • Quick Joint • Trencher Tooth

MARINE HARDWARE

• Star handle • Door hinge • Folding Dock Cleat

• Mirror Polished Mooring • Hollow base boat rope cleat • Mounting Brackets

VALVE/PUMP

• Valve body • Explosion-proof valves • Pipe fitting

OTHERS

The casting part is wildly use in the industries, such as rail&transit parts, bicycle parts, casting impeller, food machine sorting components, solar mounting system parts, container safety parts, Electronic lock body, robot parts and so on, we have more than 20 patents related to this kinds of project in production.

ADVANCED EQUIPMENTS

Our company also equiped advance inspection equipment to meet the inspection requirement of the parts, so that we can sure the part can have a good quality.

MAIN EQUIPMENT LIST

| Magnetic defect inspection | Spectrometer | HB hardness inspection | Mechanical inspection |

| Ultrasonic defect inspection | Roughness tester | HR hardness inspection | CMM inspection |

| Metallographic detector | X-ray inspection | Dye penetrant inspection | 100% Thread inspection |

FAQ

| Q1 | Are you factory or trading company? |

| A1 | We are factory located in HangZhou city, China |

| Q2 | What kinds of language is avaliable? |

| A2 | English, Chinese, except email cummunication, we are ok with video meeting and calling. |

| Q3 | How should I place an order? |

| A3 | We are receive the PO and production drawing by email. |

| Q4 | Which shipping methed is ok for you? |

| A4 | Normally shipping by sea and train is use for mass production order delivery. DHL,TNT,FedEx, UPS,EMS air shipment is use for sample delivery. |

| Q5 | How can I contact you? |

| A5 | You can contact us by email, and also we can chat by Skype, Teams, WhatsApp, Facebook. |

| Q6 | What kinds of drawing format can be use? |

| A6 | PRO/E, Auto CAD, Solid Works, IGS, UG, CAD/CAM/CAE, STEP. |

| Q7 | Which packing material do you use for sea shipping? |

| A7 | For sea shipping, we will packaging with European standard wooden pallet. The parts will packing with PE bag inside the carton box. |

| Q8 | How do you deal with the RFQ? |

| A8 | Sales receiving the RFQ—Feasiblity study meeting with R&D engineer—Feed back technical issues with Customer—Sales quoted |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Casting Method: | Thermal Gravity Casting |

|---|---|

| Process: | Precision Casting |

| Molding Technics: | Gravity Casting |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do axle shafts enhance the overall performance and drivability of vehicles?

Axle shafts play a crucial role in enhancing the overall performance and drivability of vehicles. These components are integral to the drivetrain system and are responsible for transferring power from the differential to the wheels. Here’s a detailed explanation of how axle shafts contribute to improved performance and drivability:

- Power Transmission: Axle shafts are responsible for transmitting power from the differential to the drive wheels. By efficiently transferring torque, axle shafts allow the wheels to rotate and generate forward motion. The proper functioning of axle shafts ensures that power is effectively delivered to the wheels, enabling acceleration, towing capability, and overall propulsion.

- Traction and Stability: Axle shafts, particularly in vehicles equipped with differential systems, play a crucial role in optimizing traction and stability. Differential systems allow for power distribution between the wheels, adjusting torque delivery based on wheel slip conditions. This helps to improve traction on various surfaces, such as slippery roads or uneven terrains. By ensuring better grip and stability, axle shafts contribute to safer and more confident driving experiences.

- Handling and Cornering: Axle shafts influence the handling and cornering characteristics of a vehicle. By transmitting power to the drive wheels, axle shafts enable precise control and responsiveness during steering inputs. Well-designed axle shafts with appropriate strength and flexibility properties contribute to predictable and stable handling, allowing drivers to navigate corners smoothly and maintain control over the vehicle.

- Load-Bearing Capacity: Axle shafts are subjected to significant loads, especially in vehicles that carry heavy loads or tow trailers. Robust axle shafts with adequate load-bearing capacity ensure that the vehicle can handle the weight without experiencing excessive deflection or failure. By providing sufficient strength and durability, axle shafts contribute to the safe and efficient transport of passengers and cargo.

- Efficiency and Fuel Economy: The weight and design of axle shafts can impact the overall efficiency and fuel economy of a vehicle. Lighter axle shafts, such as those made from advanced materials like aluminum or composites, can reduce the unsprung weight of the vehicle. This helps improve suspension response, reduce energy losses, and enhance fuel efficiency. Additionally, optimized designs and reduced friction in axle shafts contribute to more efficient power transmission, maximizing the energy utilization of the drivetrain system.

- Durability and Reliability: Axle shafts are subjected to various stresses and operating conditions, including high torque, vibrations, and impacts. High-quality axle shafts constructed from durable materials, engineered with appropriate geometries, and manufactured using advanced techniques offer enhanced durability and reliability. Reliable axle shafts minimize the risk of failures or breakdowns, contributing to the overall dependability of the vehicle.

In summary, axle shafts enhance the overall performance and drivability of vehicles through efficient power transmission, improved traction and stability, enhanced handling and cornering, adequate load-bearing capacity, increased efficiency and fuel economy, and enhanced durability and reliability. These components play a critical role in ensuring optimal power delivery, control, and safety, ultimately enhancing the driving experience and satisfaction of vehicle owners.

What are the advantages of using high-performance or heavy-duty axle shafts?

Using high-performance or heavy-duty axle shafts can offer several advantages in terms of strength, durability, and performance. These specialized axle shafts are designed to handle increased torque loads, provide improved power delivery, and withstand the demands of challenging applications. Here’s a detailed explanation of the advantages of using high-performance or heavy-duty axle shafts:

- Increased Strength: High-performance or heavy-duty axle shafts are typically constructed from stronger materials, such as chromoly steel or alloy steel. These materials offer higher tensile and yield strength compared to standard axle shafts. The increased strength allows the shafts to handle higher torque loads without deformation or failure, providing enhanced reliability and durability.

- Improved Power Delivery: High-performance axle shafts are designed to provide more efficient power delivery from the drivetrain to the wheels. The enhanced strength and rigidity of these shafts minimize power loss due to torsional flex, ensuring that a greater percentage of the torque generated by the engine reaches the wheels. This results in improved acceleration, better throttle response, and enhanced overall performance.

- Enhanced Torsional Rigidity: Heavy-duty axle shafts are often engineered with increased torsional rigidity. This means they have reduced torsional flex or twisting under load. The improved torsional rigidity helps maintain consistent power transfer to the wheels, especially during high-torque situations or aggressive driving maneuvers. It contributes to better traction and stability, particularly in performance-oriented or off-road applications.

- Increased Durability: High-performance or heavy-duty axle shafts are designed to withstand the demands of challenging applications. They are engineered to handle increased loads, higher rotational speeds, and more extreme operating conditions. By providing greater durability, these axle shafts can withstand off-road obstacles, heavy payloads, or aggressive driving without premature wear or failure.

- Improved Off-Road Capability: High-performance or heavy-duty axle shafts are particularly beneficial in off-road applications. They can handle the additional stresses and forces encountered during off-road driving, such as uneven terrain, rock crawling, or high-speed desert runs. With increased strength and durability, these axle shafts reduce the risk of breakage, allowing off-road enthusiasts to explore challenging terrains with more confidence.

- Support for Vehicle Modifications: High-performance or heavy-duty axle shafts are often used in vehicles with significant modifications, such as increased engine power, larger tires, or suspension upgrades. These axle shafts can accommodate the additional torque loads and provide the necessary strength and reliability to support the modified drivetrain and suspension components.

It’s important to note that the advantages of high-performance or heavy-duty axle shafts are most noticeable in applications where the vehicle is subjected to increased torque loads, extreme conditions, or performance-oriented driving. In everyday driving scenarios with standard vehicles, the benefits may be less pronounced.

When considering high-performance or heavy-duty axle shafts, it’s crucial to ensure compatibility with other drivetrain components, such as the differential, wheel hubs, and braking system. Additionally, professional installation by experienced technicians is recommended to ensure proper fitment and compatibility.

Overall, high-performance or heavy-duty axle shafts offer increased strength, improved power delivery, enhanced durability, and better performance characteristics, making them a valuable upgrade for specific applications where increased performance, reliability, and off-road capability are desired.

How does an axle shaft transfer power from the differential to the wheels?

An axle shaft serves as a crucial component in transferring power from the differential to the wheels of a vehicle. It plays a vital role in transmitting torque and enabling the wheels to rotate. Here is an explanation of how an axle shaft transfers power:

1. Differential Connection:

The axle shaft is connected to the differential, which is a device located between the transmission or transaxle and the wheels. The differential receives rotational power from the engine through the transmission or transaxle and splits it between the two axle shafts. The axle shafts are connected to the differential’s side gears or output shafts, ensuring a solid mechanical connection.

2. Torque Distribution:

As the engine generates torque, it is transferred through the drivetrain to the differential. The differential acts as a torque distributor, allocating the rotational force between the two axle shafts. In a rear-wheel-drive vehicle, the differential splits the torque equally between the two rear axle shafts. In a front-wheel-drive vehicle, the differential or transaxle distributes the torque to the two front axle shafts.

3. Power Transmission:

Once the torque is divided by the differential, each axle shaft receives a portion of the power. The axle shafts transmit this power to the respective wheels, enabling them to rotate and propel the vehicle forward or backward. The rotational force from the axle shafts is transferred to the wheel hubs or constant velocity (CV) joints, which are connected to the wheels. The wheel hubs or CV joints allow the rotational motion to be transferred to the wheels while accommodating suspension movement and steering angles.

4. Wheel Rotation:

As the axle shafts rotate, the power they transmit causes the wheels to rotate at the same speed. This rotation generates the necessary torque at the wheel contact patches, allowing the vehicle to move. The rotational motion of the wheels is essential for traction, acceleration, deceleration, and maneuverability.

5. Suspension Flexibility:

An axle shaft must also allow for suspension flex and wheel articulation. As the suspension moves up and down, the axle shafts accommodate the changes in axle length and angle. This flexibility is especially important in off-road vehicles and those equipped with independent suspension systems. In such cases, the axle shafts are designed with features like constant velocity (CV) joints or universal joints to allow for smooth power transfer even when the wheels are at different angles or positions due to suspension movement.

Overall, an axle shaft transfers power from the differential to the wheels by connecting to the differential and transmitting torque to the wheels. This power transfer enables the wheels to rotate and provides the driving force necessary for vehicle movement.

editor by CX 2024-04-13