Product Description

Product Description

Our compay always insists high-quality standard producing and continually improve ourselves since the very beginning of company’s establishment, we always contribute to make perfect combination of equipment and technology, made the high stable quality.

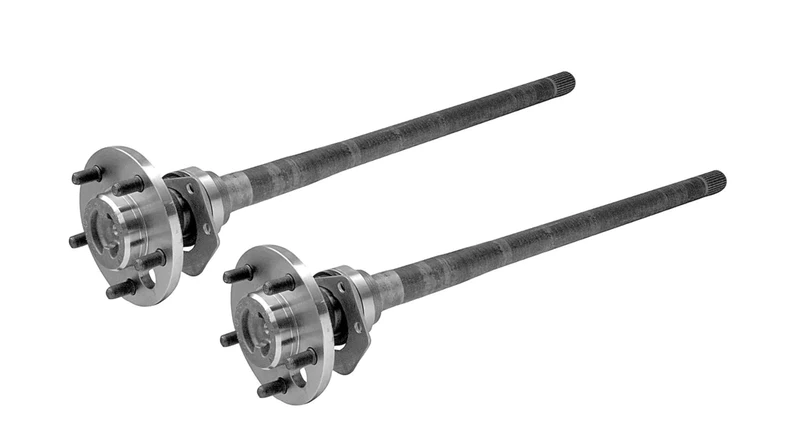

| Part Name | CV AXLE |

| Brand | AUTOJET/AAE/STOP/ as customers requirements |

| Application | Auto Transmission System |

| car maker | All AMERICAN,BIRTITSH, JAPANESS, and KOREAN |

| Placement on Vehicle | Right/ Left |

| Material | Iron/Steel |

| Warranty | 12 Months |

| Sample | Available |

| Price | Negotiable |

| Place of origin | Any Chinese port |

| Delivery time | 30-45 days after confirmed |

| Packing | Processional |

| MOQ | 100 PCS |

| Payment | L/C,T/T,Western Union,PayPal |

Detailed Photos

Main Products

Company Profile

ZheJiang CZPT Macinery equipments is a new developing manufacturing company. Producing Auto parts production lines. As well we have 15 years of exporting auto parts for all automotive products. As after market supplies. Our main products are SHOCK ABSORBING, POWER STEERING SYSTEMS, SUSPENSION, CV AXLE, CV JONTS, and AUTO LIGHTS. We have our own brands and we do customize brand for customers requirements. Our products are produced under quality control team. Two advantage we offer; Genuine parts quality and After market price best value parts. Our products has 98% warranty for 1 year form date of use. Some items are warranty per KM 98% means we accept a claim if the damaged parts more then 2% of the quantity up to manufacturing fault for After Sales Service We have different solutions for different customers. Our company is sincerely willing to cooperate with enterprises from all over the world in order to realize a CZPT situation since the trend of economic globalization has developed with an irresistible force.

Our Factories

Packaging & Shipping

FAQ

1.Are you a factory or a trading company ?

We are a factory and trading company at the same time.

2.Where is your company located ? How can I visit there ?

Our company is located in HangZhou, all clients, from home and abroad, are warmly welcomed to visit us .

3.How about the quality of the products ?

Our products are of high quality and we have registered and reputable brands.

4.What’s the MOQ for each items ?

100 pieces.

5.Could we supply samples ?

We offer samples,but the samples should be paid.

6.What’s the delivery time ?

30-45 working days after confirmed

7.What’s our shipping ways ?

We can provide different types of shipping such as sea, air, and land.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Condition: | New |

| Color: | Black |

| Certification: | ISO, IATF-16949 |

| Type: | CV Axle |

| Application Brand: | Hyundai |

| Customization: |

Available

| Customized Request |

|---|

Can axle shafts be used in various types of vehicles, from compact cars to heavy trucks?

Axle shafts are integral components of the drivetrain system in vehicles, and they are indeed used in a wide range of vehicle types, spanning from compact cars to heavy trucks. Axle shafts play a critical role in transmitting torque from the differential to the wheels, allowing for power delivery and enabling vehicle movement. Here’s a detailed explanation of how axle shafts are utilized in different types of vehicles:

Compact Cars and Sedans: Compact cars and sedans typically employ a front-wheel drive or rear-wheel drive configuration. In these vehicles, the axle shafts are responsible for transmitting power from the differential to the drive wheels. In front-wheel drive vehicles, the axle shafts connect the transaxle (combining the transmission and differential) to the front wheels. In rear-wheel drive vehicles, the axle shafts transmit power from the rear differential to the rear wheels. Axle shafts in compact cars and sedans are generally designed to handle the power and load requirements specific to these vehicle classes.

SUVs and Crossovers: Sport utility vehicles (SUVs) and crossovers often feature both front-wheel drive and all-wheel drive configurations. In these vehicles, axle shafts are utilized to transfer power to the drive wheels, whether it’s the front wheels, rear wheels, or all wheels simultaneously. In all-wheel drive systems, axle shafts connect the front and rear differentials to the respective wheels, enabling power distribution to all four wheels. The axle shafts in SUVs and crossovers are designed to handle the higher power and torque demands associated with these larger and more capable vehicles.

Pickup Trucks and Vans: Pickup trucks and vans are commonly rear-wheel drive or four-wheel drive vehicles. Rear-wheel drive trucks employ axle shafts to transmit power from the rear differential to the rear wheels, enabling propulsion. Four-wheel drive trucks and vans utilize both front and rear axle shafts to distribute power to all four wheels. These vehicles often require robust and heavy-duty axle shafts capable of handling the increased loads, towing capacities, and off-road conditions associated with these applications.

Heavy Trucks and Commercial Vehicles: Heavy trucks and commercial vehicles, such as tractor-trailers, buses, and construction vehicles, have specialized axle systems to support their substantial weight and demanding operating conditions. These vehicles typically employ multiple axles, including front steer axles and drive axles. Axle shafts in heavy trucks are designed to withstand high torque, heavy loads, and challenging terrains. They are constructed using durable materials and feature robust designs to ensure reliable performance and longevity.

Overall, axle shafts are utilized in various types of vehicles, ranging from compact cars to heavy trucks. They play a crucial role in transmitting power from the differential to the wheels, enabling vehicle movement. The design, materials, and specifications of axle shafts vary depending on the vehicle class, power requirements, and intended application.

In summary, axle shafts are essential components in a wide range of vehicles, from compact cars and sedans to SUVs, pickup trucks, heavy trucks, and commercial vehicles. Their function is to transfer power from the differential to the drive wheels, facilitating vehicle propulsion. The design and characteristics of axle shafts are tailored to meet the specific needs of each vehicle type, ensuring optimal performance and durability.

Can axle shafts be customized or upgraded for specific applications?

Axle shafts can indeed be customized or upgraded to meet specific application requirements. Depending on the intended use, performance goals, and vehicle modifications, customization or upgrading of axle shafts can provide several benefits. Here’s a detailed explanation of customizing and upgrading axle shafts for specific applications:

Customization:

Customization of axle shafts involves tailoring their design, materials, and specifications to suit specific application needs. Some common examples of axle shaft customization include:

- Material Selection: Axle shafts can be customized by choosing different materials based on the desired strength, weight, and durability. For high-performance applications, materials such as chromoly steel or alloy steel may be selected to enhance strength and withstand increased torque loads.

- Length and Splines: The length and spline count of axle shafts can be customized to accommodate vehicle modifications or specific drivetrain setups. This ensures proper fitment and engagement with the differential or transaxle and the wheel hubs.

- Upgraded CV Joints: In applications that require increased articulation or heavy-duty off-road use, the constant velocity (CV) joints on the axle shafts can be upgraded to more robust and durable versions. Upgraded CV joints can better withstand extreme angles and off-road stresses.

- Performance Enhancements: Custom axle shafts can be designed to handle higher torque loads or provide improved performance characteristics. This can involve optimizing the shaft diameter, wall thickness, or other design parameters to enhance strength, reduce weight, or increase torsional rigidity.

Upgrades:

In addition to customization, upgrading axle shafts with aftermarket components or specialized kits is another option for specific applications. Upgrades can provide enhanced performance, durability, or specialized features. Some common axle shaft upgrades include:

- Performance Axle Shafts: Aftermarket performance axle shafts are available for vehicles used in high-performance applications, such as racing or off-roading. These shafts are designed to handle increased torque loads, provide better strength, and improve power delivery efficiency.

- Locking Differentials: Upgrading to a locking differential system can enhance off-road performance by ensuring power is evenly distributed to both wheels, improving traction in challenging terrain. Upgraded axle shafts may be necessary to accommodate the locking differential mechanism.

- Upgraded Bearings and Seals: Upgrading the bearings and seals on axle shafts can improve durability and longevity. This is particularly beneficial in heavy-duty applications or environments with high levels of dust, moisture, or contaminants.

- Axle Shaft Reinforcement: For vehicles subjected to extreme loads or heavy modifications, axle shaft reinforcement kits can be installed. These kits typically include additional bracing or gussets to strengthen the axle housing and prevent bending or failure of the axle shafts.

It’s important to note that axle shaft customization or upgrading may require careful consideration of other drivetrain components, such as differential, wheel hubs, and suspension geometry. Additionally, such modifications should be performed by qualified professionals with expertise in axle shafts and drivetrain systems to ensure proper installation and compatibility.

By customizing or upgrading axle shafts to specific applications, vehicle owners can optimize performance, durability, and reliability, tailored to their unique needs and requirements.

Are there different axle shaft designs for rear-wheel drive and front-wheel drive vehicles?

Yes, rear-wheel drive (RWD) and front-wheel drive (FWD) vehicles typically employ different axle shaft designs to accommodate their respective drivetrain configurations. The axle shafts in RWD and FWD vehicles differ in their construction, orientation, and connection to the wheels. Here’s a detailed explanation of the axle shaft designs used in RWD and FWD vehicles:

Rear-Wheel Drive (RWD) Vehicles:

In RWD vehicles, the engine’s power is transmitted to the rear wheels through the drivetrain components. The axle shaft design in RWD vehicles is commonly referred to as a solid axle or full-floating axle. Here are the key characteristics of RWD axle shafts:

- Rigid Shaft: RWD axle shafts are typically solid and rigid, connecting the differential directly to each rear wheel. They are designed to handle high torque loads and provide robustness, making them suitable for heavy-duty applications.

- Single Connection: Each rear wheel has its own dedicated axle shaft, which connects directly to the wheel hub. The axle shaft transfers power to the wheel, enabling it to rotate.

- Support and Power Transfer: RWD axle shafts support the weight of the vehicle and transmit torque from the differential to the wheels. They facilitate smooth power delivery and enable the rear wheels to propel the vehicle forward or backward.

- Less Articulation: Since RWD vehicles typically have a solid rear axle, the axle shafts have limited articulation compared to FWD vehicles. This design simplifies the construction but may result in reduced suspension flexibility and a harsher ride quality.

Front-Wheel Drive (FWD) Vehicles:

In FWD vehicles, the engine’s power is transmitted to the front wheels through the drivetrain components. FWD axle shafts are commonly known as half shafts or CV axles (constant velocity axles). Here are the main characteristics of FWD axle shafts:

- Compact and Lightweight: FWD axle shafts are typically lighter and more compact than RWD axle shafts. They are designed to accommodate the space limitations in the front-wheel-drive layout.

- Constant Velocity (CV) Joints: FWD axle shafts incorporate constant velocity (CV) joints, which allow for flexibility and rotation at various angles. CV joints compensate for the changing length and angle of the axle shafts during suspension movement and steering.

- Transverse Orientation: FWD axle shafts are positioned transversely across the vehicle, connecting the differential or transaxle to the front wheels. This orientation allows for efficient power transfer and space utilization in FWD vehicles.

- Support and Power Transfer: FWD axle shafts support the weight of the vehicle and transmit torque from the differential or transaxle to the front wheels. They enable the front wheels to rotate and provide the driving force for vehicle movement.

- Increased Articulation: FWD axle shafts have greater articulation capabilities due to the need to accommodate suspension movement and steering angles. The CV joints allow the axle shafts to flex and rotate, ensuring smooth power delivery even when the wheels are turned or the suspension is compressed.

These axle shaft designs in RWD and FWD vehicles are tailored to the specific requirements and configurations of each drivetrain layout. They optimize power transmission, support the wheels, and ensure efficient operation based on the unique characteristics of rear-wheel drive and front-wheel drive systems.

editor by CX 2024-04-24

China Custom CZPT OEM 8r0501203b 2X CV Axle Shaft Assembly for Audi A6 A7 A8 Quattro RS7 S7 Sq5 Rear Left & Right bad axle symptoms

Product Description

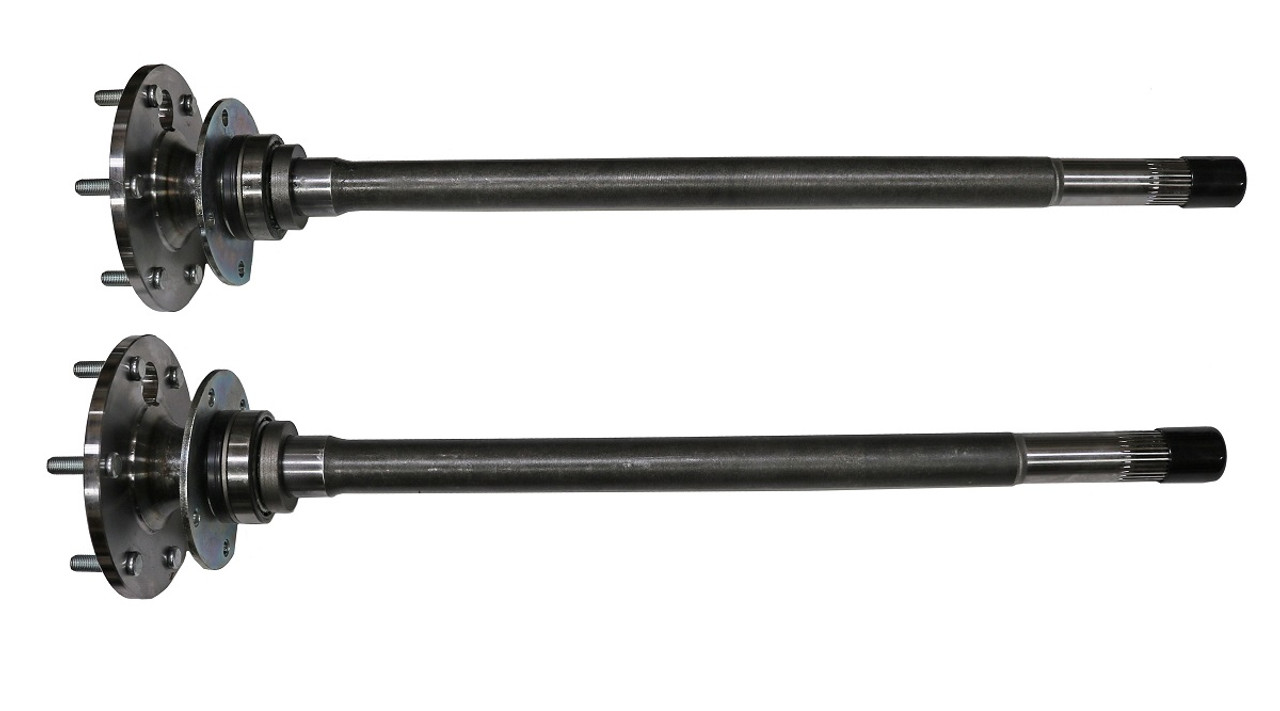

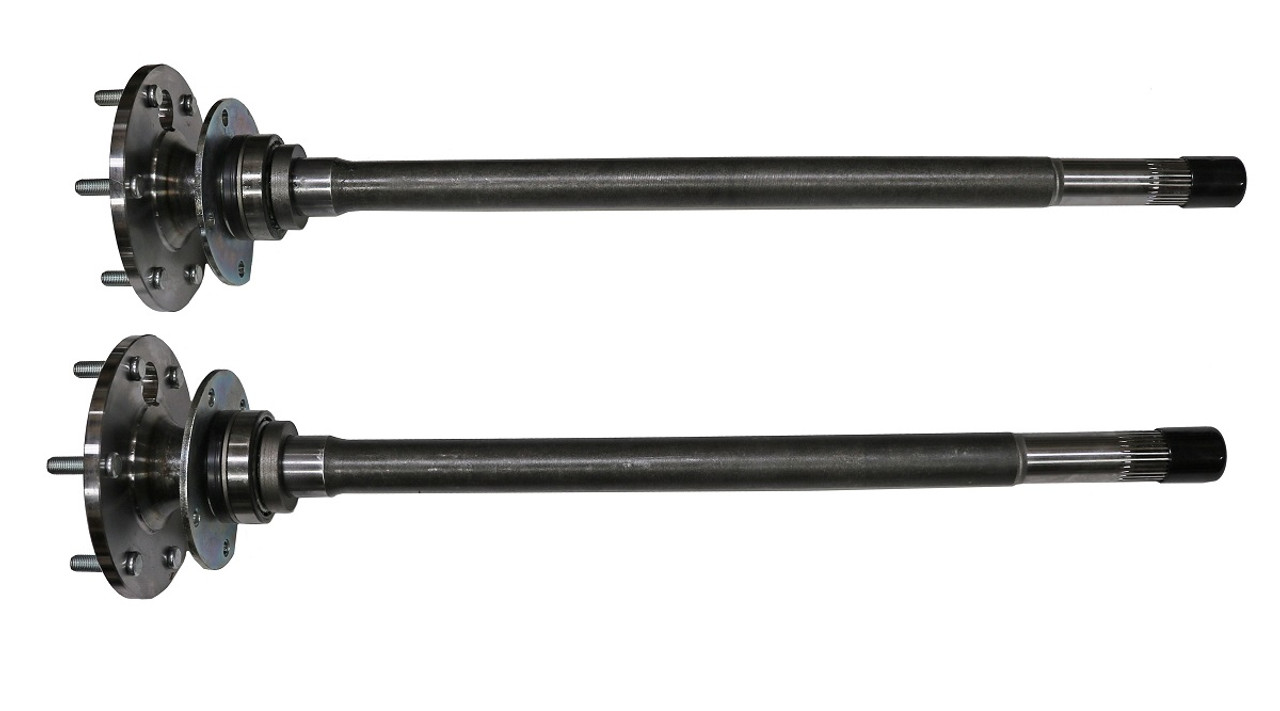

SENP OEM 8R0501203B 2x CV Axle Shaft Assembly for Audi A6 A7 A8 Quattro RS7 S7 SQ5 Rear Left & Right

|

Product Type |

CV Axle Shaft Assembly |

|

OE No. |

8R0501203B |

|

Suitable for |

for Audi A6 A7 A8 Quattro RS7 S7 SQ5 |

|

Weight |

4 kg |

|

Brand |

SENP |

|

Certification |

ISO9001 |

|

MOQ |

1 PC |

|

Packing |

SENP packing, neutral packing, client’s packing |

|

Warranty |

24 months / 80000km |

|

Payment term |

T/T, Paypal, Western Union |

FQA:

Q1.Where is your company?

A: Our Head Office are located in HangZhou City, ZheJiang Province, China(Mainland);

Q2. What is your terms of packing?

A: Generally, we pack our goods in SENP boxes or neutral boxes

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q4. What is your terms of delivery?

A: EXW, FOB,

Q5. How about your delivery time?

A: Generally, it will take about 20 days after receiving your deposit. The specific delivery time depends on the items and the

quantity of your order.

Q6. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q7. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier costs.

Q8. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q9. How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers’ benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24 Hours Online Services |

|---|---|

| Condition: | New |

| Color: | Silver |

| Certification: | ISO |

| Type: | Drive Shaft Assembly |

| Material: | Aluminum |

| Samples: |

US$ 120/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can axle shafts be used in various types of vehicles, from compact cars to heavy trucks?

Axle shafts are integral components of the drivetrain system in vehicles, and they are indeed used in a wide range of vehicle types, spanning from compact cars to heavy trucks. Axle shafts play a critical role in transmitting torque from the differential to the wheels, allowing for power delivery and enabling vehicle movement. Here’s a detailed explanation of how axle shafts are utilized in different types of vehicles:

Compact Cars and Sedans: Compact cars and sedans typically employ a front-wheel drive or rear-wheel drive configuration. In these vehicles, the axle shafts are responsible for transmitting power from the differential to the drive wheels. In front-wheel drive vehicles, the axle shafts connect the transaxle (combining the transmission and differential) to the front wheels. In rear-wheel drive vehicles, the axle shafts transmit power from the rear differential to the rear wheels. Axle shafts in compact cars and sedans are generally designed to handle the power and load requirements specific to these vehicle classes.

SUVs and Crossovers: Sport utility vehicles (SUVs) and crossovers often feature both front-wheel drive and all-wheel drive configurations. In these vehicles, axle shafts are utilized to transfer power to the drive wheels, whether it’s the front wheels, rear wheels, or all wheels simultaneously. In all-wheel drive systems, axle shafts connect the front and rear differentials to the respective wheels, enabling power distribution to all four wheels. The axle shafts in SUVs and crossovers are designed to handle the higher power and torque demands associated with these larger and more capable vehicles.

Pickup Trucks and Vans: Pickup trucks and vans are commonly rear-wheel drive or four-wheel drive vehicles. Rear-wheel drive trucks employ axle shafts to transmit power from the rear differential to the rear wheels, enabling propulsion. Four-wheel drive trucks and vans utilize both front and rear axle shafts to distribute power to all four wheels. These vehicles often require robust and heavy-duty axle shafts capable of handling the increased loads, towing capacities, and off-road conditions associated with these applications.

Heavy Trucks and Commercial Vehicles: Heavy trucks and commercial vehicles, such as tractor-trailers, buses, and construction vehicles, have specialized axle systems to support their substantial weight and demanding operating conditions. These vehicles typically employ multiple axles, including front steer axles and drive axles. Axle shafts in heavy trucks are designed to withstand high torque, heavy loads, and challenging terrains. They are constructed using durable materials and feature robust designs to ensure reliable performance and longevity.

Overall, axle shafts are utilized in various types of vehicles, ranging from compact cars to heavy trucks. They play a crucial role in transmitting power from the differential to the wheels, enabling vehicle movement. The design, materials, and specifications of axle shafts vary depending on the vehicle class, power requirements, and intended application.

In summary, axle shafts are essential components in a wide range of vehicles, from compact cars and sedans to SUVs, pickup trucks, heavy trucks, and commercial vehicles. Their function is to transfer power from the differential to the drive wheels, facilitating vehicle propulsion. The design and characteristics of axle shafts are tailored to meet the specific needs of each vehicle type, ensuring optimal performance and durability.

Can you provide examples of classic and modern vehicles that use various axle shafts?

Various classic and modern vehicles utilize different types of axle shafts depending on their design, drivetrain configuration, and intended use. Here are examples of classic and modern vehicles that use various axle shafts:

Classic Vehicles:

- Ford Mustang (Classic): Classic Ford Mustang models, such as the first-generation Mustangs produced in the 1960s, typically featured solid rear axle shafts. These axle shafts were commonly made of forged steel and provided simplicity and durability in a rear-wheel drive configuration.

- Jeep Wrangler (Classic): Classic Jeep Wrangler models, such as the Jeep CJ series, often utilized solid front and rear axle shafts. These axle shafts were designed to handle the demands of off-road driving and provided ruggedness and reliability in a four-wheel drive setup.

- Volkswagen Beetle (Classic): The classic Volkswagen Beetle, produced from the 1930s to the 2000s, featured independent rear suspension with CV (constant velocity) axle shafts. These axle shafts allowed for smooth power delivery and improved handling characteristics.

Modern Vehicles:

- Ford F-150 (Modern): The Ford F-150, a popular full-size pickup truck, utilizes various axle shaft configurations depending on the model and drivetrain options. Rear-wheel drive versions may employ solid axle shafts, while four-wheel drive models can feature independent front suspension with CV axle shafts and a solid rear axle.

- Toyota Camry (Modern): The Toyota Camry, a mid-size sedan, typically incorporates front-wheel drive with independent front suspension and CV axle shafts. These axle shafts provide smooth power transfer and allow for improved maneuverability and efficiency.

- Jeep Wrangler (Modern): The modern Jeep Wrangler continues to utilize solid front and rear axle shafts, maintaining its off-road capability and durability. The solid axle shafts contribute to the Wrangler’s exceptional ground clearance and ability to handle challenging terrains.

- Tesla Model S (Modern): The Tesla Model S, an all-electric luxury sedan, utilizes electric motor-driven axle shafts instead of traditional mechanical axle shafts. These electric motor-driven axle shafts deliver instant torque to the wheels, providing impressive acceleration and performance.

It’s important to note that the specific axle shaft configurations and materials used in vehicles can vary even within the same model due to different trim levels, drivetrain options, and technological advancements. Additionally, aftermarket modifications can further alter the axle shaft setups in vehicles to accommodate specific needs and preferences.

When considering axle shafts for replacement or upgrades, it’s crucial to ensure compatibility with the vehicle’s make, model, and drivetrain configuration. Consulting with a professional mechanic or referencing the manufacturer’s specifications is recommended to ensure the correct axle shaft selection.

In summary, classic and modern vehicles utilize various axle shaft configurations, including solid axle shafts, CV axle shafts, and electric motor-driven axle shafts. These axle shafts are tailored to the specific needs of the vehicle, such as durability, off-road capability, power delivery, and efficiency.

How does axle shaft length and material affect a vehicle’s performance?

The length and material of an axle shaft can have an impact on a vehicle’s performance in several ways. Both factors play a role in determining the vehicle’s handling, power delivery, efficiency, and overall drivability. Here’s a detailed explanation of how axle shaft length and material affect a vehicle’s performance:

Axle Shaft Length:

The length of the axle shaft refers to the distance between the differential or transaxle and the wheel hub. The axle shaft length can influence the following aspects of a vehicle’s performance:

- Traction and Stability: A longer axle shaft can provide increased stability and traction, especially in situations where weight transfer occurs during acceleration or cornering. The longer length helps distribute the vehicle’s weight more evenly between the wheels, enhancing grip and stability.

- Turning Radius: The length of the axle shaft affects a vehicle’s turning radius. Generally, a shorter axle shaft allows for a tighter turning radius, making it easier to maneuver in tight spaces or negotiate sharp turns. On the other hand, a longer axle shaft may result in a larger turning radius, requiring more space for turning maneuvers.

- Ground Clearance: The length of the axle shaft can impact a vehicle’s ground clearance. A shorter axle shaft may provide higher ground clearance, which can be advantageous for off-road vehicles or those designed for rugged terrain. Conversely, a longer axle shaft may reduce ground clearance, potentially limiting the vehicle’s ability to navigate obstacles.

Axle Shaft Material:

The material used in the construction of an axle shaft can significantly influence a vehicle’s performance characteristics. Here are some ways in which axle shaft material can impact performance:

- Strength and Durability: The material of the axle shaft determines its strength and durability. High-strength materials, such as alloy steel or specialized composites, can withstand higher torque loads and provide enhanced durability, making them suitable for high-performance or heavy-duty applications. Stronger materials also contribute to improved reliability and reduced risk of axle shaft failure.

- Weight Reduction: The choice of lightweight materials, such as aluminum or carbon fiber, for the axle shaft can help reduce overall vehicle weight. A lighter axle shaft contributes to improved fuel efficiency, handling, and acceleration. It also reduces unsprung weight, which positively affects the vehicle’s suspension dynamics and responsiveness.

- Flexibility and Damping: Some axle shaft materials possess inherent flexibility or damping properties that can influence the vehicle’s ride quality and handling characteristics. Certain composite materials or designs can help absorb vibrations and shocks from the road surface, contributing to a smoother and more comfortable ride.

- Cost and Manufacturing: The choice of axle shaft material can impact manufacturing costs and feasibility. Some materials may be more expensive or require specialized manufacturing processes, affecting the overall cost of the vehicle. Additionally, material availability and ease of fabrication can influence the practicality of using certain materials for axle shaft construction.

It’s important to note that axle shaft length and material selection are typically determined by the vehicle manufacturer based on various considerations, including the intended purpose of the vehicle, performance targets, cost factors, and engineering requirements. Optimizing axle shaft length and material can contribute to achieving the desired balance of performance, handling, durability, and efficiency for a specific vehicle application.

editor by CX 2024-04-23

China Standard High Precision Engine Stainless Carbon Flexible Spline Motor Axle Gear Shaft axle carrier

Product Description

1. Are you manufacturer or trade company ?

We are a manufacturing factory founded in 1987 ,with trade team for international service.

2. What terms of payment you usually use ?

T/T . 30% deposit ,and 70% before finish production .Price :FOB ZheJiang .

3. Can you make products according to customer”s design ?

Yes , we can make according to customer”s drawing and samples .OED and ODM are acceptable.

4.How long is your delivery time ?

Genarally it is 5-15 days afte rthe deposit .It will take more days customized.

5. What do I need for offering a quote ?

Please offer us 2D or 3d drawing (with material ,dimension,surface treatment and other technical datas etc.), quantity ,or samples .

Then we will quote the best price .

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Revolution Axis |

| Stiffness & Flexibility: | Flexible Shaft |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can axle shafts be used in various types of vehicles, from compact cars to heavy trucks?

Axle shafts are integral components of the drivetrain system in vehicles, and they are indeed used in a wide range of vehicle types, spanning from compact cars to heavy trucks. Axle shafts play a critical role in transmitting torque from the differential to the wheels, allowing for power delivery and enabling vehicle movement. Here’s a detailed explanation of how axle shafts are utilized in different types of vehicles:

Compact Cars and Sedans: Compact cars and sedans typically employ a front-wheel drive or rear-wheel drive configuration. In these vehicles, the axle shafts are responsible for transmitting power from the differential to the drive wheels. In front-wheel drive vehicles, the axle shafts connect the transaxle (combining the transmission and differential) to the front wheels. In rear-wheel drive vehicles, the axle shafts transmit power from the rear differential to the rear wheels. Axle shafts in compact cars and sedans are generally designed to handle the power and load requirements specific to these vehicle classes.

SUVs and Crossovers: Sport utility vehicles (SUVs) and crossovers often feature both front-wheel drive and all-wheel drive configurations. In these vehicles, axle shafts are utilized to transfer power to the drive wheels, whether it’s the front wheels, rear wheels, or all wheels simultaneously. In all-wheel drive systems, axle shafts connect the front and rear differentials to the respective wheels, enabling power distribution to all four wheels. The axle shafts in SUVs and crossovers are designed to handle the higher power and torque demands associated with these larger and more capable vehicles.

Pickup Trucks and Vans: Pickup trucks and vans are commonly rear-wheel drive or four-wheel drive vehicles. Rear-wheel drive trucks employ axle shafts to transmit power from the rear differential to the rear wheels, enabling propulsion. Four-wheel drive trucks and vans utilize both front and rear axle shafts to distribute power to all four wheels. These vehicles often require robust and heavy-duty axle shafts capable of handling the increased loads, towing capacities, and off-road conditions associated with these applications.

Heavy Trucks and Commercial Vehicles: Heavy trucks and commercial vehicles, such as tractor-trailers, buses, and construction vehicles, have specialized axle systems to support their substantial weight and demanding operating conditions. These vehicles typically employ multiple axles, including front steer axles and drive axles. Axle shafts in heavy trucks are designed to withstand high torque, heavy loads, and challenging terrains. They are constructed using durable materials and feature robust designs to ensure reliable performance and longevity.

Overall, axle shafts are utilized in various types of vehicles, ranging from compact cars to heavy trucks. They play a crucial role in transmitting power from the differential to the wheels, enabling vehicle movement. The design, materials, and specifications of axle shafts vary depending on the vehicle class, power requirements, and intended application.

In summary, axle shafts are essential components in a wide range of vehicles, from compact cars and sedans to SUVs, pickup trucks, heavy trucks, and commercial vehicles. Their function is to transfer power from the differential to the drive wheels, facilitating vehicle propulsion. The design and characteristics of axle shafts are tailored to meet the specific needs of each vehicle type, ensuring optimal performance and durability.

Can axle shafts be customized or upgraded for specific applications?

Axle shafts can indeed be customized or upgraded to meet specific application requirements. Depending on the intended use, performance goals, and vehicle modifications, customization or upgrading of axle shafts can provide several benefits. Here’s a detailed explanation of customizing and upgrading axle shafts for specific applications:

Customization:

Customization of axle shafts involves tailoring their design, materials, and specifications to suit specific application needs. Some common examples of axle shaft customization include:

- Material Selection: Axle shafts can be customized by choosing different materials based on the desired strength, weight, and durability. For high-performance applications, materials such as chromoly steel or alloy steel may be selected to enhance strength and withstand increased torque loads.

- Length and Splines: The length and spline count of axle shafts can be customized to accommodate vehicle modifications or specific drivetrain setups. This ensures proper fitment and engagement with the differential or transaxle and the wheel hubs.

- Upgraded CV Joints: In applications that require increased articulation or heavy-duty off-road use, the constant velocity (CV) joints on the axle shafts can be upgraded to more robust and durable versions. Upgraded CV joints can better withstand extreme angles and off-road stresses.

- Performance Enhancements: Custom axle shafts can be designed to handle higher torque loads or provide improved performance characteristics. This can involve optimizing the shaft diameter, wall thickness, or other design parameters to enhance strength, reduce weight, or increase torsional rigidity.

Upgrades:

In addition to customization, upgrading axle shafts with aftermarket components or specialized kits is another option for specific applications. Upgrades can provide enhanced performance, durability, or specialized features. Some common axle shaft upgrades include:

- Performance Axle Shafts: Aftermarket performance axle shafts are available for vehicles used in high-performance applications, such as racing or off-roading. These shafts are designed to handle increased torque loads, provide better strength, and improve power delivery efficiency.

- Locking Differentials: Upgrading to a locking differential system can enhance off-road performance by ensuring power is evenly distributed to both wheels, improving traction in challenging terrain. Upgraded axle shafts may be necessary to accommodate the locking differential mechanism.

- Upgraded Bearings and Seals: Upgrading the bearings and seals on axle shafts can improve durability and longevity. This is particularly beneficial in heavy-duty applications or environments with high levels of dust, moisture, or contaminants.

- Axle Shaft Reinforcement: For vehicles subjected to extreme loads or heavy modifications, axle shaft reinforcement kits can be installed. These kits typically include additional bracing or gussets to strengthen the axle housing and prevent bending or failure of the axle shafts.

It’s important to note that axle shaft customization or upgrading may require careful consideration of other drivetrain components, such as differential, wheel hubs, and suspension geometry. Additionally, such modifications should be performed by qualified professionals with expertise in axle shafts and drivetrain systems to ensure proper installation and compatibility.

By customizing or upgrading axle shafts to specific applications, vehicle owners can optimize performance, durability, and reliability, tailored to their unique needs and requirements.

Are there different axle shaft designs for rear-wheel drive and front-wheel drive vehicles?

Yes, rear-wheel drive (RWD) and front-wheel drive (FWD) vehicles typically employ different axle shaft designs to accommodate their respective drivetrain configurations. The axle shafts in RWD and FWD vehicles differ in their construction, orientation, and connection to the wheels. Here’s a detailed explanation of the axle shaft designs used in RWD and FWD vehicles:

Rear-Wheel Drive (RWD) Vehicles:

In RWD vehicles, the engine’s power is transmitted to the rear wheels through the drivetrain components. The axle shaft design in RWD vehicles is commonly referred to as a solid axle or full-floating axle. Here are the key characteristics of RWD axle shafts:

- Rigid Shaft: RWD axle shafts are typically solid and rigid, connecting the differential directly to each rear wheel. They are designed to handle high torque loads and provide robustness, making them suitable for heavy-duty applications.

- Single Connection: Each rear wheel has its own dedicated axle shaft, which connects directly to the wheel hub. The axle shaft transfers power to the wheel, enabling it to rotate.

- Support and Power Transfer: RWD axle shafts support the weight of the vehicle and transmit torque from the differential to the wheels. They facilitate smooth power delivery and enable the rear wheels to propel the vehicle forward or backward.

- Less Articulation: Since RWD vehicles typically have a solid rear axle, the axle shafts have limited articulation compared to FWD vehicles. This design simplifies the construction but may result in reduced suspension flexibility and a harsher ride quality.

Front-Wheel Drive (FWD) Vehicles:

In FWD vehicles, the engine’s power is transmitted to the front wheels through the drivetrain components. FWD axle shafts are commonly known as half shafts or CV axles (constant velocity axles). Here are the main characteristics of FWD axle shafts:

- Compact and Lightweight: FWD axle shafts are typically lighter and more compact than RWD axle shafts. They are designed to accommodate the space limitations in the front-wheel-drive layout.

- Constant Velocity (CV) Joints: FWD axle shafts incorporate constant velocity (CV) joints, which allow for flexibility and rotation at various angles. CV joints compensate for the changing length and angle of the axle shafts during suspension movement and steering.

- Transverse Orientation: FWD axle shafts are positioned transversely across the vehicle, connecting the differential or transaxle to the front wheels. This orientation allows for efficient power transfer and space utilization in FWD vehicles.

- Support and Power Transfer: FWD axle shafts support the weight of the vehicle and transmit torque from the differential or transaxle to the front wheels. They enable the front wheels to rotate and provide the driving force for vehicle movement.

- Increased Articulation: FWD axle shafts have greater articulation capabilities due to the need to accommodate suspension movement and steering angles. The CV joints allow the axle shafts to flex and rotate, ensuring smooth power delivery even when the wheels are turned or the suspension is compressed.

These axle shaft designs in RWD and FWD vehicles are tailored to the specific requirements and configurations of each drivetrain layout. They optimize power transmission, support the wheels, and ensure efficient operation based on the unique characteristics of rear-wheel drive and front-wheel drive systems.

editor by CX 2024-04-23

China manufacturer Rear Axle Shaft 4231126290 for CZPT Hiace Rh/Lh 42311-26290 axle dump

Product Description

| 1.Item Name: |

Propeller shaft |

| 2.OE NO.: |

42311-26290 |

| 3.Car Make: |

for CZPT Hilux |

| 4.Part Type: | chasiss system |

| 5.MOQ: | 30 PCS |

| 6. Price : | EXW Price |

| 7.Shipping Way: | By Sea, DHL, UPS, FEDEX or as customers’ requirements |

| 8.Payment Terms: | Via T/T ,L/C ,Paypal ,Westerm Union,Moneygram. |

| 9.Delivery Time: | Within 30 days after deposit or as customers’ requirement |

| 10.Packaging:Packaging: |

1.Carton Box, 4.We can perform according to customer’s requirements |

Ideer Established in 2571, which is a professional manufacturer and exporter that is concerned with the design, development and production of auto parts. We are located in HangZhou, with convenient transportation access. All of our productscomply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Covering an area of 10000 square meters, we now have over 100 employees, an annual sales figure that exceeds USD 300,000 and are currently exporting 80% of our production worldwide. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Besides, we have received ISO9001 and CE.As a result of our high quality products and outstanding customer service, we have gained a global sales network CZPT South America.

If you are interested in any of our products or would like to discuss a customorder, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24 Hours |

|---|---|

| Warranty: | 1 Year |

| Type: | Other Engine Parts |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does proper maintenance extend the lifespan of axle shafts and drivetrains?

Proper maintenance plays a crucial role in extending the lifespan of axle shafts and drivetrains in vehicles. By following recommended maintenance practices, owners can prevent premature wear, identify potential issues early, and ensure optimal performance. Here’s a detailed explanation of how proper maintenance extends the lifespan of axle shafts and drivetrains:

- Lubrication: Regular lubrication is essential for axle shafts and drivetrain components. Adequate lubrication reduces friction between moving parts, minimizing wear and heat generation. It helps prevent metal-to-metal contact, which can lead to damage and premature failure. Proper lubrication ensures smooth operation and protects against corrosion, promoting the longevity of axle shafts and drivetrain components.

- Fluid Inspection and Replacement: Regular inspection and replacement of fluids, such as gear oil and transmission fluid, are essential for maintaining the health of axle shafts and drivetrains. Over time, fluids can become contaminated, lose their lubricating properties, or develop excessive wear particles. By regularly inspecting and replacing fluids according to the manufacturer’s recommendations, owners can ensure optimal lubrication and cooling, reducing the risk of component damage and extending the lifespan of axle shafts and drivetrains.

- Seal and Boot Maintenance: Axle shafts are equipped with seals and boots that protect them from contamination and retain lubricants. Proper maintenance involves inspecting and replacing damaged or worn seals and boots. Cracked or torn boots can allow dirt, moisture, and debris to enter, leading to accelerated wear and potential damage to the axle shafts and other drivetrain components. Regular maintenance of seals and boots helps maintain a protective barrier, preserving the integrity and longevity of the axle shafts and drivetrains.

- Alignment and Suspension: Proper alignment and suspension settings are crucial for the health of axle shafts and drivetrains. Misalignment or improper suspension geometry can place excessive stress on the axle shafts, leading to premature wear or failure. Regular wheel alignment and suspension inspections, as well as addressing any issues promptly, help distribute the load evenly across the axle shafts, reducing strain and extending their lifespan.

- Regular Inspections: Conducting regular inspections of the axle shafts and drivetrain components allows owners to identify any signs of wear, damage, or abnormalities. This includes checking for excessive play, unusual noises, leaks, or vibrations. By catching potential issues early, owners can take timely action, such as repairing or replacing worn components, preventing further damage and preserving the overall health and longevity of the axle shafts and drivetrains.

- Proper Driving Habits: Responsible driving habits can also contribute to the extended lifespan of axle shafts and drivetrains. Avoiding aggressive acceleration, hard braking, and abrupt shifts can reduce stress on these components. Smooth and controlled driving minimizes sudden torque changes and excessive forces, preventing unnecessary wear and extending the life of axle shafts and drivetrains.

By adhering to proper maintenance practices, owners can significantly increase the lifespan of axle shafts and drivetrains in their vehicles. Regular lubrication, fluid inspection and replacement, seal and boot maintenance, alignment and suspension checks, regular inspections, and adopting responsible driving habits all contribute to reducing wear, preventing damage, and maximizing the performance and longevity of axle shafts and drivetrains.

In summary, proper maintenance plays a vital role in extending the lifespan of axle shafts and drivetrains. It ensures adequate lubrication, inspects and replaces fluids, maintains seals and boots, addresses alignment and suspension issues, conducts regular inspections, and promotes responsible driving. By following these practices, owners can enjoy a longer lifespan and optimal performance from their vehicle’s axle shafts and drivetrains.

How do axle shafts contribute to a vehicle’s stability and handling?

Axle shafts play a crucial role in contributing to a vehicle’s stability and handling characteristics. They are integral components of the suspension and drivetrain systems, affecting how the vehicle distributes power, maintains traction, and responds to steering inputs. Here’s a detailed explanation of how axle shafts contribute to a vehicle’s stability and handling:

- Power Distribution: Axle shafts transmit power from the drivetrain to the wheels, allowing the vehicle to move forward or backward. The distribution of power between the wheels is essential for maintaining stability and preventing wheel slippage. By transferring torque evenly to the wheels, axle shafts help optimize traction and prevent excessive power loss, ensuring that the vehicle stays stable and controlled during acceleration or deceleration.

- Traction Control: Axle shafts, particularly those equipped with differential mechanisms, help maintain traction by allowing the wheels to rotate at different speeds when necessary. This feature is especially important during turns or when driving on uneven surfaces. The differential compensates for differences in wheel rotation, enabling the vehicle to maintain stability and grip by preventing wheel spin or loss of control.

- Suspension Geometry: Axle shafts are integrated into the suspension system, connecting the wheels to the differential or transaxle. The positioning and design of axle shafts influence the suspension geometry, including factors like camber, caster, and toe. Proper suspension geometry is crucial for stability, predictable handling, and optimal tire contact with the road surface. Well-engineered axle shafts ensure that the suspension components work harmoniously to maintain stability and enhance handling characteristics.

- Steering Response: In vehicles with front-wheel drive or all-wheel drive configurations, axle shafts are responsible for transmitting power to the front wheels while also allowing for steering inputs. This design affects the vehicle’s steering response and handling. High-quality axle shafts with minimal play or backlash contribute to precise steering control, allowing the driver to make accurate and predictable maneuvers. Axle shafts that provide a direct and responsive connection between the drivetrain and front wheels enhance the overall handling and stability of the vehicle.

- Weight Distribution: The weight distribution of a vehicle affects its stability and handling characteristics. Axle shafts, particularly those in rear-wheel drive vehicles, support the weight of the vehicle’s rear end. By properly distributing the weight across the axles, axle shafts help maintain a balanced and stable platform. This balanced weight distribution enhances the vehicle’s overall stability and allows for better handling during cornering, reducing the risk of oversteer or understeer.

- Impact on Suspension Tuning: Axle shafts can have an impact on the tuning and performance of the suspension system. Upgrading to high-performance axle shafts, such as those made from stronger materials or featuring improved designs, can enhance the overall rigidity and responsiveness of the suspension. This, in turn, improves the vehicle’s stability and handling, allowing for more precise control during aggressive driving or challenging road conditions.

It’s important to note that while axle shafts contribute significantly to a vehicle’s stability and handling, they work in conjunction with other components such as suspension, tires, steering system, and chassis design. The overall performance and characteristics of a vehicle’s stability and handling are the result of a complex interaction between these components.

In summary, axle shafts contribute to a vehicle’s stability and handling by ensuring proper power distribution, maintaining traction control, influencing suspension geometry, providing responsive steering, contributing to balanced weight distribution, and impacting suspension tuning. High-quality axle shafts that are properly engineered and integrated into the vehicle’s systems enhance stability, improve handling characteristics, and allow for a more controlled and enjoyable driving experience.

How does axle shaft length and material affect a vehicle’s performance?

The length and material of an axle shaft can have an impact on a vehicle’s performance in several ways. Both factors play a role in determining the vehicle’s handling, power delivery, efficiency, and overall drivability. Here’s a detailed explanation of how axle shaft length and material affect a vehicle’s performance:

Axle Shaft Length:

The length of the axle shaft refers to the distance between the differential or transaxle and the wheel hub. The axle shaft length can influence the following aspects of a vehicle’s performance:

- Traction and Stability: A longer axle shaft can provide increased stability and traction, especially in situations where weight transfer occurs during acceleration or cornering. The longer length helps distribute the vehicle’s weight more evenly between the wheels, enhancing grip and stability.

- Turning Radius: The length of the axle shaft affects a vehicle’s turning radius. Generally, a shorter axle shaft allows for a tighter turning radius, making it easier to maneuver in tight spaces or negotiate sharp turns. On the other hand, a longer axle shaft may result in a larger turning radius, requiring more space for turning maneuvers.

- Ground Clearance: The length of the axle shaft can impact a vehicle’s ground clearance. A shorter axle shaft may provide higher ground clearance, which can be advantageous for off-road vehicles or those designed for rugged terrain. Conversely, a longer axle shaft may reduce ground clearance, potentially limiting the vehicle’s ability to navigate obstacles.

Axle Shaft Material:

The material used in the construction of an axle shaft can significantly influence a vehicle’s performance characteristics. Here are some ways in which axle shaft material can impact performance:

- Strength and Durability: The material of the axle shaft determines its strength and durability. High-strength materials, such as alloy steel or specialized composites, can withstand higher torque loads and provide enhanced durability, making them suitable for high-performance or heavy-duty applications. Stronger materials also contribute to improved reliability and reduced risk of axle shaft failure.

- Weight Reduction: The choice of lightweight materials, such as aluminum or carbon fiber, for the axle shaft can help reduce overall vehicle weight. A lighter axle shaft contributes to improved fuel efficiency, handling, and acceleration. It also reduces unsprung weight, which positively affects the vehicle’s suspension dynamics and responsiveness.

- Flexibility and Damping: Some axle shaft materials possess inherent flexibility or damping properties that can influence the vehicle’s ride quality and handling characteristics. Certain composite materials or designs can help absorb vibrations and shocks from the road surface, contributing to a smoother and more comfortable ride.

- Cost and Manufacturing: The choice of axle shaft material can impact manufacturing costs and feasibility. Some materials may be more expensive or require specialized manufacturing processes, affecting the overall cost of the vehicle. Additionally, material availability and ease of fabrication can influence the practicality of using certain materials for axle shaft construction.

It’s important to note that axle shaft length and material selection are typically determined by the vehicle manufacturer based on various considerations, including the intended purpose of the vehicle, performance targets, cost factors, and engineering requirements. Optimizing axle shaft length and material can contribute to achieving the desired balance of performance, handling, durability, and efficiency for a specific vehicle application.

editor by CX 2024-04-23

China high quality Splined Yokes Axle Shaft Tractor Spare Parts Transmission Shaft Tractor Pto Drive Shaft axle for car

Product Description

HangZhou Hongri Machinery Manufacture Co., Ltd

Product Description

PTO shaft

Product Parameters

Packaging & Shipping

Packing:

Normal packing or According to your requirement.

Safe, complete and fast delivery of goods to customers.

Shipping: By sea

Payment Terms: T/T

Company Profile

| Business type | Manufacture |

| Location | Shiliwang Industrial Zone of HangZhou, ZheJiang ,China |

| Year Established | 2003 |

| Occupied area | 50 Acres |

| Company certification | CE, ISO9001,SGS |

| Main product | disc harrow, disc plough, trailer, boom sprayer , rotary tillers, potato planter ,plowing blade, plough blade, soil-loosening shovel and so on. With good quality, excellent performance, our products annually export to countries around the world, and we have gained the majority of customers trust. |

After Sales Service

After Service: 12 months guarantee of the main parts, we will send the guarantee parts together with the machine in your next order or we can send them by air express if you need it urgently.

FAQ

1.Q: Full price list for these products

A: If you need the price list for these products, please notify the product model so that I can quote you accordingly. Please understand we have a very wide product range, we don’t usually offer full products price list.

2. Q: Business terms

A: Shipment time: 25-40days after your payment

Shipment: By sea

Loading port: HangZhou port, China

Destination port: …To be advised

Payment: T/T

Warranty: 1 year

3.Q:How can I order from you?

A: Please send us your enquiry list; we will reply you within 2 working days.

4.Q:If the finger I look for are not in your catalogue, what should I do?

A: We can develop it according to your drawing or sample.

5. Q: Why choose Hongri for cooperation?

A: Comparing with our competitors, we have much more advantages as follows:

– More than 30years in manufacturing farming machine

– More Professional Sales staffs to guarantee the better service

– More agri machines for your choice

– More New products into your range to avoid price competition

– Larger quantity production and shipment

– Better quality to guarantee better Credit.

– Faster delivery time: Only7days

– More stick quality checking before shipment.

– More reasonable after-sales service terms.

– More famous brand: Hongri” brand and “CE”ceitification.

– Lower repair rate and bad review rate

– We have American Branch to show our main products. We can give customers best service.

Please feel free to contact me if you have any questions.

Thanks. Have a nice day!

Contact me

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage |

|---|---|

| Material: | Carbon Steel |

| Power Source: | Tractor |

| After-sales Service: | 1 Year |

| Warranty: | 1 Year |

| Yoke Type: | Push Pin/Quick Release/Ball |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can axle shafts be used in various types of vehicles, from compact cars to heavy trucks?

Axle shafts are integral components of the drivetrain system in vehicles, and they are indeed used in a wide range of vehicle types, spanning from compact cars to heavy trucks. Axle shafts play a critical role in transmitting torque from the differential to the wheels, allowing for power delivery and enabling vehicle movement. Here’s a detailed explanation of how axle shafts are utilized in different types of vehicles:

Compact Cars and Sedans: Compact cars and sedans typically employ a front-wheel drive or rear-wheel drive configuration. In these vehicles, the axle shafts are responsible for transmitting power from the differential to the drive wheels. In front-wheel drive vehicles, the axle shafts connect the transaxle (combining the transmission and differential) to the front wheels. In rear-wheel drive vehicles, the axle shafts transmit power from the rear differential to the rear wheels. Axle shafts in compact cars and sedans are generally designed to handle the power and load requirements specific to these vehicle classes.

SUVs and Crossovers: Sport utility vehicles (SUVs) and crossovers often feature both front-wheel drive and all-wheel drive configurations. In these vehicles, axle shafts are utilized to transfer power to the drive wheels, whether it’s the front wheels, rear wheels, or all wheels simultaneously. In all-wheel drive systems, axle shafts connect the front and rear differentials to the respective wheels, enabling power distribution to all four wheels. The axle shafts in SUVs and crossovers are designed to handle the higher power and torque demands associated with these larger and more capable vehicles.

Pickup Trucks and Vans: Pickup trucks and vans are commonly rear-wheel drive or four-wheel drive vehicles. Rear-wheel drive trucks employ axle shafts to transmit power from the rear differential to the rear wheels, enabling propulsion. Four-wheel drive trucks and vans utilize both front and rear axle shafts to distribute power to all four wheels. These vehicles often require robust and heavy-duty axle shafts capable of handling the increased loads, towing capacities, and off-road conditions associated with these applications.

Heavy Trucks and Commercial Vehicles: Heavy trucks and commercial vehicles, such as tractor-trailers, buses, and construction vehicles, have specialized axle systems to support their substantial weight and demanding operating conditions. These vehicles typically employ multiple axles, including front steer axles and drive axles. Axle shafts in heavy trucks are designed to withstand high torque, heavy loads, and challenging terrains. They are constructed using durable materials and feature robust designs to ensure reliable performance and longevity.

Overall, axle shafts are utilized in various types of vehicles, ranging from compact cars to heavy trucks. They play a crucial role in transmitting power from the differential to the wheels, enabling vehicle movement. The design, materials, and specifications of axle shafts vary depending on the vehicle class, power requirements, and intended application.

In summary, axle shafts are essential components in a wide range of vehicles, from compact cars and sedans to SUVs, pickup trucks, heavy trucks, and commercial vehicles. Their function is to transfer power from the differential to the drive wheels, facilitating vehicle propulsion. The design and characteristics of axle shafts are tailored to meet the specific needs of each vehicle type, ensuring optimal performance and durability.

Can you provide examples of classic and modern vehicles that use various axle shafts?

Various classic and modern vehicles utilize different types of axle shafts depending on their design, drivetrain configuration, and intended use. Here are examples of classic and modern vehicles that use various axle shafts:

Classic Vehicles:

- Ford Mustang (Classic): Classic Ford Mustang models, such as the first-generation Mustangs produced in the 1960s, typically featured solid rear axle shafts. These axle shafts were commonly made of forged steel and provided simplicity and durability in a rear-wheel drive configuration.

- Jeep Wrangler (Classic): Classic Jeep Wrangler models, such as the Jeep CJ series, often utilized solid front and rear axle shafts. These axle shafts were designed to handle the demands of off-road driving and provided ruggedness and reliability in a four-wheel drive setup.

- Volkswagen Beetle (Classic): The classic Volkswagen Beetle, produced from the 1930s to the 2000s, featured independent rear suspension with CV (constant velocity) axle shafts. These axle shafts allowed for smooth power delivery and improved handling characteristics.

Modern Vehicles:

- Ford F-150 (Modern): The Ford F-150, a popular full-size pickup truck, utilizes various axle shaft configurations depending on the model and drivetrain options. Rear-wheel drive versions may employ solid axle shafts, while four-wheel drive models can feature independent front suspension with CV axle shafts and a solid rear axle.

- Toyota Camry (Modern): The Toyota Camry, a mid-size sedan, typically incorporates front-wheel drive with independent front suspension and CV axle shafts. These axle shafts provide smooth power transfer and allow for improved maneuverability and efficiency.

- Jeep Wrangler (Modern): The modern Jeep Wrangler continues to utilize solid front and rear axle shafts, maintaining its off-road capability and durability. The solid axle shafts contribute to the Wrangler’s exceptional ground clearance and ability to handle challenging terrains.

- Tesla Model S (Modern): The Tesla Model S, an all-electric luxury sedan, utilizes electric motor-driven axle shafts instead of traditional mechanical axle shafts. These electric motor-driven axle shafts deliver instant torque to the wheels, providing impressive acceleration and performance.

It’s important to note that the specific axle shaft configurations and materials used in vehicles can vary even within the same model due to different trim levels, drivetrain options, and technological advancements. Additionally, aftermarket modifications can further alter the axle shaft setups in vehicles to accommodate specific needs and preferences.

When considering axle shafts for replacement or upgrades, it’s crucial to ensure compatibility with the vehicle’s make, model, and drivetrain configuration. Consulting with a professional mechanic or referencing the manufacturer’s specifications is recommended to ensure the correct axle shaft selection.

In summary, classic and modern vehicles utilize various axle shaft configurations, including solid axle shafts, CV axle shafts, and electric motor-driven axle shafts. These axle shafts are tailored to the specific needs of the vehicle, such as durability, off-road capability, power delivery, and efficiency.

How does an axle shaft transfer power from the differential to the wheels?

An axle shaft serves as a crucial component in transferring power from the differential to the wheels of a vehicle. It plays a vital role in transmitting torque and enabling the wheels to rotate. Here is an explanation of how an axle shaft transfers power:

1. Differential Connection:

The axle shaft is connected to the differential, which is a device located between the transmission or transaxle and the wheels. The differential receives rotational power from the engine through the transmission or transaxle and splits it between the two axle shafts. The axle shafts are connected to the differential’s side gears or output shafts, ensuring a solid mechanical connection.

2. Torque Distribution:

As the engine generates torque, it is transferred through the drivetrain to the differential. The differential acts as a torque distributor, allocating the rotational force between the two axle shafts. In a rear-wheel-drive vehicle, the differential splits the torque equally between the two rear axle shafts. In a front-wheel-drive vehicle, the differential or transaxle distributes the torque to the two front axle shafts.

3. Power Transmission:

Once the torque is divided by the differential, each axle shaft receives a portion of the power. The axle shafts transmit this power to the respective wheels, enabling them to rotate and propel the vehicle forward or backward. The rotational force from the axle shafts is transferred to the wheel hubs or constant velocity (CV) joints, which are connected to the wheels. The wheel hubs or CV joints allow the rotational motion to be transferred to the wheels while accommodating suspension movement and steering angles.

4. Wheel Rotation:

As the axle shafts rotate, the power they transmit causes the wheels to rotate at the same speed. This rotation generates the necessary torque at the wheel contact patches, allowing the vehicle to move. The rotational motion of the wheels is essential for traction, acceleration, deceleration, and maneuverability.

5. Suspension Flexibility:

An axle shaft must also allow for suspension flex and wheel articulation. As the suspension moves up and down, the axle shafts accommodate the changes in axle length and angle. This flexibility is especially important in off-road vehicles and those equipped with independent suspension systems. In such cases, the axle shafts are designed with features like constant velocity (CV) joints or universal joints to allow for smooth power transfer even when the wheels are at different angles or positions due to suspension movement.

Overall, an axle shaft transfers power from the differential to the wheels by connecting to the differential and transmitting torque to the wheels. This power transfer enables the wheels to rotate and provides the driving force necessary for vehicle movement.

editor by CX 2024-04-23

China Hot selling Wholesale Automobile Parts Automobile Half Axle Ball Cage Assembly Front Drive Shaft Semiaxis Suitable for CZPT Pegas 49500-H7000/H7100 49501-H7000/H7100 axle bar

Product Description

| Name of an article | semiaxis |

| Model | 49500-H7000/H7100 49504-H7000/H7100 |

| Car make and model | KIA PEGAS |

| Quality | New original |

| Delivery time | 2-3 days in stock and 15-30 days out of stock |

| Port | ZheJiang /HangZhou/ZheJiang /or the port you want |

| Mode of transport | Air/sea/land transport |

Automobile Xihu (West Lake) Dis. CZPT CZPT Automobile Parts Co., Ltd. is a company specializing in the production and sales of high-quality Hyundai/Kia automobile parts made in MOBIS and China, mainly supplying Hyundai and Kia engines, chassis and body parts. Founded in 2006, the company has more than 40 employees.

Looking forward to your inquiry.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Customer First, Quality First. |

|---|---|

| Condition: | New |

| Axle Number: | 2 |

| Samples: |

US$ 70/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do axle shafts enhance the overall performance and drivability of vehicles?

Axle shafts play a crucial role in enhancing the overall performance and drivability of vehicles. These components are integral to the drivetrain system and are responsible for transferring power from the differential to the wheels. Here’s a detailed explanation of how axle shafts contribute to improved performance and drivability:

- Power Transmission: Axle shafts are responsible for transmitting power from the differential to the drive wheels. By efficiently transferring torque, axle shafts allow the wheels to rotate and generate forward motion. The proper functioning of axle shafts ensures that power is effectively delivered to the wheels, enabling acceleration, towing capability, and overall propulsion.

- Traction and Stability: Axle shafts, particularly in vehicles equipped with differential systems, play a crucial role in optimizing traction and stability. Differential systems allow for power distribution between the wheels, adjusting torque delivery based on wheel slip conditions. This helps to improve traction on various surfaces, such as slippery roads or uneven terrains. By ensuring better grip and stability, axle shafts contribute to safer and more confident driving experiences.

- Handling and Cornering: Axle shafts influence the handling and cornering characteristics of a vehicle. By transmitting power to the drive wheels, axle shafts enable precise control and responsiveness during steering inputs. Well-designed axle shafts with appropriate strength and flexibility properties contribute to predictable and stable handling, allowing drivers to navigate corners smoothly and maintain control over the vehicle.

- Load-Bearing Capacity: Axle shafts are subjected to significant loads, especially in vehicles that carry heavy loads or tow trailers. Robust axle shafts with adequate load-bearing capacity ensure that the vehicle can handle the weight without experiencing excessive deflection or failure. By providing sufficient strength and durability, axle shafts contribute to the safe and efficient transport of passengers and cargo.

- Efficiency and Fuel Economy: The weight and design of axle shafts can impact the overall efficiency and fuel economy of a vehicle. Lighter axle shafts, such as those made from advanced materials like aluminum or composites, can reduce the unsprung weight of the vehicle. This helps improve suspension response, reduce energy losses, and enhance fuel efficiency. Additionally, optimized designs and reduced friction in axle shafts contribute to more efficient power transmission, maximizing the energy utilization of the drivetrain system.

- Durability and Reliability: Axle shafts are subjected to various stresses and operating conditions, including high torque, vibrations, and impacts. High-quality axle shafts constructed from durable materials, engineered with appropriate geometries, and manufactured using advanced techniques offer enhanced durability and reliability. Reliable axle shafts minimize the risk of failures or breakdowns, contributing to the overall dependability of the vehicle.

In summary, axle shafts enhance the overall performance and drivability of vehicles through efficient power transmission, improved traction and stability, enhanced handling and cornering, adequate load-bearing capacity, increased efficiency and fuel economy, and enhanced durability and reliability. These components play a critical role in ensuring optimal power delivery, control, and safety, ultimately enhancing the driving experience and satisfaction of vehicle owners.

What is the role of axle shafts in the functionality and safety of a vehicle?

The axle shafts play a crucial role in the functionality and safety of a vehicle’s drivetrain. These components are responsible for transmitting torque from the differential or transaxle to the wheels, enabling power delivery and facilitating smooth vehicle operation. Here’s a detailed explanation of the role of axle shafts in the functionality and safety of a vehicle:

Power Transmission:

The primary function of axle shafts is to transfer rotational power from the engine to the wheels. When the engine generates torque, it travels through the transmission system and reaches the differential or transaxle. From there, the axle shafts transmit the torque to the individual wheels, allowing them to rotate and propel the vehicle forward or backward. Axle shafts ensure efficient power transmission, enabling the vehicle to accelerate, maintain speed, and climb inclines effectively.

Wheel Connectivity:

Axle shafts serve as the physical link between the wheels and the drivetrain. They connect the wheels to the differential or transaxle, ensuring that the rotational force generated by the engine is effectively transferred to each wheel. This connectivity enables synchronized wheel movement and coordination, ensuring stable handling, traction, and control of the vehicle.

Suspension Support:

Axle shafts also provide support to the vehicle’s suspension system. They are part of the suspension geometry and assist in maintaining proper wheel alignment and positioning. Axle shafts help bear the weight of the vehicle and absorb various forces and vibrations encountered while driving, contributing to a smoother and more comfortable ride. Additionally, they assist in managing weight transfer during acceleration, braking, and cornering, enhancing stability and handling characteristics.

Drivetrain Safety:

Axle shafts contribute to the safety of the vehicle’s drivetrain in several ways:

- Wheel Power Distribution: By transmitting torque to each wheel, axle shafts ensure balanced power distribution. This helps prevent excessive wheel spin or loss of traction, improving overall stability and control, especially in challenging driving conditions such as slippery surfaces or uneven terrain.

- Steering Control: Axle shafts play a role in the vehicle’s steering system, especially in vehicles with front-wheel drive or all-wheel drive configurations. They assist in transferring the rotational force to the front wheels, allowing for precise steering control and responsiveness.

- Braking Performance: Axle shafts contribute to the effectiveness of the braking system. As the wheels decelerate during braking, the rotational force is transmitted through the axle shafts to the differential or transaxle, facilitating proper distribution of braking force to all wheels. This helps maintain stability, prevent skidding, and ensure efficient braking performance.

Overall Vehicle Safety:

Proper functionality of axle shafts isessential for the overall safety of the vehicle:

- Preventing Catastrophic Failures: Well-maintained and properly functioning axle shafts reduce the risk of catastrophic failures that can lead to loss of control or accidents. Regular inspections and timely repairs or replacements help ensure that the axle shafts are in good condition and can withstand the forces and stresses encountered during normal driving.

- Enhancing Stability and Handling: Axle shafts contribute to the stability and handling characteristics of the vehicle. By facilitating proper power transmission and wheel connectivity, they help maintain traction, prevent wheel slippage, and improve overall vehicle control during various driving maneuvers.

- Supporting Suspension Components: Axle shafts provide support to other suspension components, such as control arms, struts, and springs. In doing so, they assist in maintaining proper suspension geometry, which is critical for safe and predictable handling. A well-functioning suspension system helps absorb shocks, maintain tire contact with the road, and provide a comfortable ride.

- Contributing to Braking Efficiency: The proper functioning of axle shafts ensures effective distribution of braking force to all wheels, enhancing the vehicle’s braking performance and reducing stopping distances. This contributes to overall safety by allowing the driver to maintain control and respond to emergency situations more effectively.