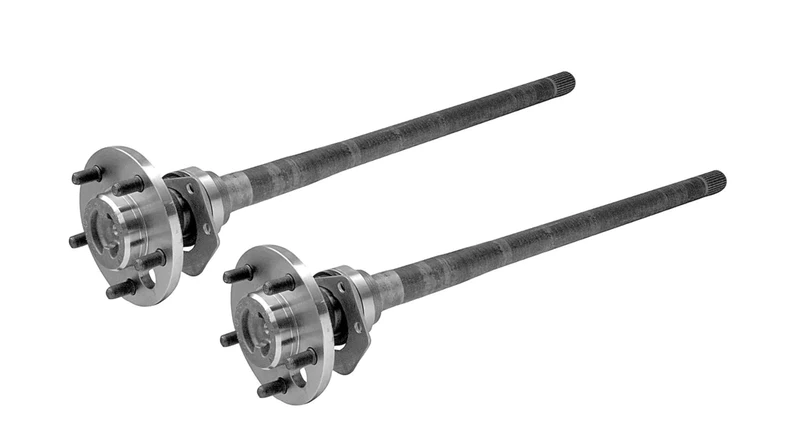

Product Description

Product Description

Warranty

1 Year

Applicable Industries

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

Weight (KG)

1

Showroom Location

Viet Nam

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

Ordinary Product

Warranty of core components

1 Year

Core Components

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Material

steel

Place of Origin

ZheJiang , China

Condition

New

Structure

Shaft

Coatings

Customized

Torque Capacity

Customized

Model Number

Customized

Brand Name

NON

Description

Shaft

Machining equipment

CNC mill,lathe and grind machine

Material

stainless steel, aluminium, carbon

Surface

Grinding and polishing

Shape

Customized

Sampling time

10days

Production time

20days

Packing

Protective packing

Tolerance

±0.001

OEM

Welcome

Production Process

Company Profile

HangZhou HUANENGDA SPRING CO.,LTD

HangZhou HuaNengDa Spring Co., Ltd. is located in Tong ‘an District, HangZhou City, ZheJiang Province, China. It is a hardware factory specializing in R&D design, manufacture and sales of precision components. The company introduces domestic and foreign advanced equipment and production technology, adopts CNC high-precision computer machine, compression spring machine, CNC five-axis linkage machining center, CNC turning and milling compound, 300 tons of punch and other mechanical equipment,and employs senior engineers with more than 10 years of work experience to debug mechanical equipment and customize production.

With the business philosophy of honesty, pragmatism and excellence, HuaNengDa Spring Company is dedicated to serving customers at home and abroad. We hope that the products of HuaNengDa will help your business to be more brilliant, let us build a bright future in the high-tech era!

The testimony is pragmatic and the attitude of the people. Quality service is the pursuit of the people!

Factory Workshop

Production Procedur

Quality Inspection

Packing And Shipping

Our Service

FAQ

1.Small order quantity is workable

From the initial sample design of the spring to the mass production of the springs, we can quickly reach your manufacturing goals and immediately provide the best products because we have an excellent production management system and expertly trained technical personnel.

2.Committed to high quality production

To keep HuaNengDa Springs at the forefront of the industry, we have implemented a stringent internal quality control system and regularly import the latest manufacturing equipment and instruments. Through our precise manufacturing technology and expert mold making process, we provide our customers with the best products and service.

3.Efficiency in manufacturing

Our company’s machinery and equipment are controlled by CNC computers. In order to respond to international needs and standards, we continuously update and upgrade our equipment every year. Our machines effectively increase production capacity and save on manufacturing costs. The manufacturing department is the most important core of the whole company and by treating it with utmost importance, we reap great benefits in manufacturing efficiency.

4.Excellent customization services

HuaNengDa’s R&D team designs and completes customized products according to the needs of customers. From the selection of materials to the function of the products, we can design and develop products to suite different customers’ requirements. We are constantly involving ourselves in all aspects of the industry because only by having a complete view and analysis of the industry, can there be innovative breakthroughs.

Payment term

*T/T : 30% pre T/T, 70% before delivery.

*Trade Assurance

Service

*Delivery on time.

*Shipped by a convenient and cost-effective way.

*Good after-selling, 24 hours service for you.

Packing

*A: Poly bag, Plstic tray ,small box, carton.

*B: According to customers’ requirements.

Delivery

*Sample: 7-10 days after deposit received.

*Batch goods: 12-15 days after samples approved. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Certification: | ISO9001 |

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Material: | Steel,Stainless Steel,Iron |

| Application: | Metal Processing Machinery Parts |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can axle shafts be used in various types of vehicles, from compact cars to heavy trucks?

Axle shafts are integral components of the drivetrain system in vehicles, and they are indeed used in a wide range of vehicle types, spanning from compact cars to heavy trucks. Axle shafts play a critical role in transmitting torque from the differential to the wheels, allowing for power delivery and enabling vehicle movement. Here’s a detailed explanation of how axle shafts are utilized in different types of vehicles:

Compact Cars and Sedans: Compact cars and sedans typically employ a front-wheel drive or rear-wheel drive configuration. In these vehicles, the axle shafts are responsible for transmitting power from the differential to the drive wheels. In front-wheel drive vehicles, the axle shafts connect the transaxle (combining the transmission and differential) to the front wheels. In rear-wheel drive vehicles, the axle shafts transmit power from the rear differential to the rear wheels. Axle shafts in compact cars and sedans are generally designed to handle the power and load requirements specific to these vehicle classes.

SUVs and Crossovers: Sport utility vehicles (SUVs) and crossovers often feature both front-wheel drive and all-wheel drive configurations. In these vehicles, axle shafts are utilized to transfer power to the drive wheels, whether it’s the front wheels, rear wheels, or all wheels simultaneously. In all-wheel drive systems, axle shafts connect the front and rear differentials to the respective wheels, enabling power distribution to all four wheels. The axle shafts in SUVs and crossovers are designed to handle the higher power and torque demands associated with these larger and more capable vehicles.

Pickup Trucks and Vans: Pickup trucks and vans are commonly rear-wheel drive or four-wheel drive vehicles. Rear-wheel drive trucks employ axle shafts to transmit power from the rear differential to the rear wheels, enabling propulsion. Four-wheel drive trucks and vans utilize both front and rear axle shafts to distribute power to all four wheels. These vehicles often require robust and heavy-duty axle shafts capable of handling the increased loads, towing capacities, and off-road conditions associated with these applications.

Heavy Trucks and Commercial Vehicles: Heavy trucks and commercial vehicles, such as tractor-trailers, buses, and construction vehicles, have specialized axle systems to support their substantial weight and demanding operating conditions. These vehicles typically employ multiple axles, including front steer axles and drive axles. Axle shafts in heavy trucks are designed to withstand high torque, heavy loads, and challenging terrains. They are constructed using durable materials and feature robust designs to ensure reliable performance and longevity.

Overall, axle shafts are utilized in various types of vehicles, ranging from compact cars to heavy trucks. They play a crucial role in transmitting power from the differential to the wheels, enabling vehicle movement. The design, materials, and specifications of axle shafts vary depending on the vehicle class, power requirements, and intended application.

In summary, axle shafts are essential components in a wide range of vehicles, from compact cars and sedans to SUVs, pickup trucks, heavy trucks, and commercial vehicles. Their function is to transfer power from the differential to the drive wheels, facilitating vehicle propulsion. The design and characteristics of axle shafts are tailored to meet the specific needs of each vehicle type, ensuring optimal performance and durability.

Can you describe the maintenance and repair considerations for axle shafts?

Maintenance and repair of axle shafts are essential to ensure the proper functioning and longevity of a vehicle’s drivetrain. Regular maintenance and timely repairs can help prevent costly damages and maintain optimal performance. Here’s a detailed explanation of the maintenance and repair considerations for axle shafts:

Maintenance Considerations:

To keep the axle shafts in good condition, the following maintenance practices are recommended:

- Inspections: Regularly inspect the axle shafts for signs of damage, such as cracks, bends, or excessive wear. Inspect the CV joints, bearings, seals, and retaining devices for leaks, deterioration, or looseness. Pay attention to any unusual noises, vibrations, or fluid leaks that may indicate potential issues.

- Lubrication: Ensure proper lubrication of the axle shafts, CV joints, and bearings as recommended by the vehicle manufacturer. Lubrication helps reduce friction, prevent excessive wear, and extend the lifespan of the components. Check the lubricant levels and quality during routine maintenance and top up or replace the lubricant as needed.

- Seal Protection: Inspect the seals around the axle shafts for damage or leaks. Damaged seals can allow contaminants, such as dirt, moisture, and debris, to enter the axle assembly, leading to premature wear and potential failure of the components. Replace damaged seals promptly to maintain proper protection.

- Boot Inspection: If the axle shafts have constant velocity (CV) joints, inspect the protective boots regularly. The boots cover the CV joints and keep them protected and lubricated. Look for any signs of cracks, tears, or leaking grease. Damaged boots should be replaced promptly to prevent dirt and moisture from entering the CV joints.

- Wheel Bearing Maintenance: If the axle shafts incorporate wheel bearings, follow the manufacturer’s recommendations for bearing maintenance. This may include periodic inspection, cleaning, re-greasing, or replacement of the wheel bearings to ensure smooth rotation and prevent excessive wear.

Repair Considerations:

If axle shaft issues are identified through inspections or during routine maintenance, the following repair considerations should be taken into account:

- Evaluation and Diagnosis: When encountering axle shaft problems, it’s important to accurately diagnose the issue before proceeding with repairs. This may involve a visual inspection, listening for abnormal noises, performing tests, or seeking professional assistance to identify the specific cause of the problem.

- Component Replacement: Depending on the nature and severity of the issue, repair options may vary. In some cases, replacing individual components such as CV joints, bearings, or seals may be sufficient. However, if the axle shaft itself is damaged or worn beyond repair, it may be necessary to replace the entire axle shaft assembly.

- Professional Expertise: Axle shaft repairs can be complex and require specialized knowledge and tools. It is often recommended to seek the assistance of a qualified mechanic or technician who has experience working with axle shafts. They can provide proper diagnosis, perform repairs accurately, and ensure the correct installation of components.

- Quality Parts: When replacing axle shaft components or the entire assembly, it is crucial to use high-quality parts that meet or exceed the manufacturer’s specifications. Using genuine or reputable aftermarket parts can help ensure proper fit, performance, and durability.

- Alignment and Calibration: After axle shaft repairs or replacements, it may be necessary to perform wheel alignment and calibration procedures to ensure proper suspension geometry, wheel balance, and drivetrain synchronization. This helps maintain vehicle stability, tire wear, and overall performance.

By following these maintenance practices and considering the appropriate repair steps, owners can help keep axle shafts in optimal condition, minimize the risk of failure, and ensure the reliable operation of the vehicle’s drivetrain.

How does an axle shaft transfer power from the differential to the wheels?

An axle shaft serves as a crucial component in transferring power from the differential to the wheels of a vehicle. It plays a vital role in transmitting torque and enabling the wheels to rotate. Here is an explanation of how an axle shaft transfers power:

1. Differential Connection:

The axle shaft is connected to the differential, which is a device located between the transmission or transaxle and the wheels. The differential receives rotational power from the engine through the transmission or transaxle and splits it between the two axle shafts. The axle shafts are connected to the differential’s side gears or output shafts, ensuring a solid mechanical connection.

2. Torque Distribution:

As the engine generates torque, it is transferred through the drivetrain to the differential. The differential acts as a torque distributor, allocating the rotational force between the two axle shafts. In a rear-wheel-drive vehicle, the differential splits the torque equally between the two rear axle shafts. In a front-wheel-drive vehicle, the differential or transaxle distributes the torque to the two front axle shafts.

3. Power Transmission:

Once the torque is divided by the differential, each axle shaft receives a portion of the power. The axle shafts transmit this power to the respective wheels, enabling them to rotate and propel the vehicle forward or backward. The rotational force from the axle shafts is transferred to the wheel hubs or constant velocity (CV) joints, which are connected to the wheels. The wheel hubs or CV joints allow the rotational motion to be transferred to the wheels while accommodating suspension movement and steering angles.

4. Wheel Rotation:

As the axle shafts rotate, the power they transmit causes the wheels to rotate at the same speed. This rotation generates the necessary torque at the wheel contact patches, allowing the vehicle to move. The rotational motion of the wheels is essential for traction, acceleration, deceleration, and maneuverability.

5. Suspension Flexibility:

An axle shaft must also allow for suspension flex and wheel articulation. As the suspension moves up and down, the axle shafts accommodate the changes in axle length and angle. This flexibility is especially important in off-road vehicles and those equipped with independent suspension systems. In such cases, the axle shafts are designed with features like constant velocity (CV) joints or universal joints to allow for smooth power transfer even when the wheels are at different angles or positions due to suspension movement.

Overall, an axle shaft transfers power from the differential to the wheels by connecting to the differential and transmitting torque to the wheels. This power transfer enables the wheels to rotate and provides the driving force necessary for vehicle movement.

editor by CX 2024-04-04

China Professional Balancing Machine Twin Casco Flex Shaft Shredder Switch 3-Pin Carbon Fiber Pool Cue Drive Bicycle Axle Shaft broken axle cost

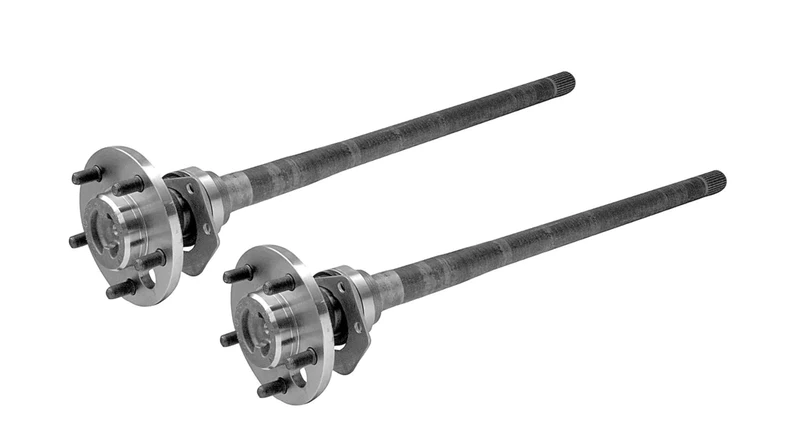

Product Description

Product Description

Warranty

1 Year

Applicable Industries

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

Weight (KG)

1

Showroom Location

Viet Nam

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

Ordinary Product

Warranty of core components

1 Year

Core Components

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Material

steel

Place of Origin

ZheJiang , China

Condition

New

Structure

Shaft

Coatings

Customized

Torque Capacity

Customized

Model Number

Customized

Brand Name

NON

Description

Shaft

Machining equipment

CNC mill,lathe and grind machine

Material

stainless steel, aluminium, carbon

Surface

Grinding and polishing

Shape

Customized

Sampling time

10days

Production time

20days

Packing

Protective packing

Tolerance

±0.001

OEM

Welcome

Production Process

Company Profile

HangZhou HUANENGDA SPRING CO.,LTD

HangZhou HuaNengDa Spring Co., Ltd. is located in Tong ‘an District, HangZhou City, ZheJiang Province, China. It is a hardware factory specializing in R&D design, manufacture and sales of precision components. The company introduces domestic and foreign advanced equipment and production technology, adopts CNC high-precision computer machine, compression spring machine, CNC five-axis linkage machining center, CNC turning and milling compound, 300 tons of punch and other mechanical equipment,and employs senior engineers with more than 10 years of work experience to debug mechanical equipment and customize production.

With the business philosophy of honesty, pragmatism and excellence, HuaNengDa Spring Company is dedicated to serving customers at home and abroad. We hope that the products of HuaNengDa will help your business to be more brilliant, let us build a bright future in the high-tech era!

The testimony is pragmatic and the attitude of the people. Quality service is the pursuit of the people!

Factory Workshop

Production Procedur

Quality Inspection

Packing And Shipping

Our Service

FAQ

1.Small order quantity is workable

From the initial sample design of the spring to the mass production of the springs, we can quickly reach your manufacturing goals and immediately provide the best products because we have an excellent production management system and expertly trained technical personnel.

2.Committed to high quality production

To keep HuaNengDa Springs at the forefront of the industry, we have implemented a stringent internal quality control system and regularly import the latest manufacturing equipment and instruments. Through our precise manufacturing technology and expert mold making process, we provide our customers with the best products and service.

3.Efficiency in manufacturing

Our company’s machinery and equipment are controlled by CNC computers. In order to respond to international needs and standards, we continuously update and upgrade our equipment every year. Our machines effectively increase production capacity and save on manufacturing costs. The manufacturing department is the most important core of the whole company and by treating it with utmost importance, we reap great benefits in manufacturing efficiency.

4.Excellent customization services

HuaNengDa’s R&D team designs and completes customized products according to the needs of customers. From the selection of materials to the function of the products, we can design and develop products to suite different customers’ requirements. We are constantly involving ourselves in all aspects of the industry because only by having a complete view and analysis of the industry, can there be innovative breakthroughs.

Payment term

*T/T : 30% pre T/T, 70% before delivery.

*Trade Assurance

Service

*Delivery on time.

*Shipped by a convenient and cost-effective way.

*Good after-selling, 24 hours service for you.

Packing

*A: Poly bag, Plstic tray ,small box, carton.

*B: According to customers’ requirements.

Delivery

*Sample: 7-10 days after deposit received.

*Batch goods: 12-15 days after samples approved.

| Condition: | New |

|---|---|

| Certification: | ISO9001 |

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Material: | Steel,Stainless Steel,Iron |

| Application: | Metal Processing Machinery Parts |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can axle shafts be used in various types of vehicles, from compact cars to heavy trucks?

Axle shafts are integral components of the drivetrain system in vehicles, and they are indeed used in a wide range of vehicle types, spanning from compact cars to heavy trucks. Axle shafts play a critical role in transmitting torque from the differential to the wheels, allowing for power delivery and enabling vehicle movement. Here’s a detailed explanation of how axle shafts are utilized in different types of vehicles:

Compact Cars and Sedans: Compact cars and sedans typically employ a front-wheel drive or rear-wheel drive configuration. In these vehicles, the axle shafts are responsible for transmitting power from the differential to the drive wheels. In front-wheel drive vehicles, the axle shafts connect the transaxle (combining the transmission and differential) to the front wheels. In rear-wheel drive vehicles, the axle shafts transmit power from the rear differential to the rear wheels. Axle shafts in compact cars and sedans are generally designed to handle the power and load requirements specific to these vehicle classes.

SUVs and Crossovers: Sport utility vehicles (SUVs) and crossovers often feature both front-wheel drive and all-wheel drive configurations. In these vehicles, axle shafts are utilized to transfer power to the drive wheels, whether it’s the front wheels, rear wheels, or all wheels simultaneously. In all-wheel drive systems, axle shafts connect the front and rear differentials to the respective wheels, enabling power distribution to all four wheels. The axle shafts in SUVs and crossovers are designed to handle the higher power and torque demands associated with these larger and more capable vehicles.

Pickup Trucks and Vans: Pickup trucks and vans are commonly rear-wheel drive or four-wheel drive vehicles. Rear-wheel drive trucks employ axle shafts to transmit power from the rear differential to the rear wheels, enabling propulsion. Four-wheel drive trucks and vans utilize both front and rear axle shafts to distribute power to all four wheels. These vehicles often require robust and heavy-duty axle shafts capable of handling the increased loads, towing capacities, and off-road conditions associated with these applications.

Heavy Trucks and Commercial Vehicles: Heavy trucks and commercial vehicles, such as tractor-trailers, buses, and construction vehicles, have specialized axle systems to support their substantial weight and demanding operating conditions. These vehicles typically employ multiple axles, including front steer axles and drive axles. Axle shafts in heavy trucks are designed to withstand high torque, heavy loads, and challenging terrains. They are constructed using durable materials and feature robust designs to ensure reliable performance and longevity.

Overall, axle shafts are utilized in various types of vehicles, ranging from compact cars to heavy trucks. They play a crucial role in transmitting power from the differential to the wheels, enabling vehicle movement. The design, materials, and specifications of axle shafts vary depending on the vehicle class, power requirements, and intended application.

In summary, axle shafts are essential components in a wide range of vehicles, from compact cars and sedans to SUVs, pickup trucks, heavy trucks, and commercial vehicles. Their function is to transfer power from the differential to the drive wheels, facilitating vehicle propulsion. The design and characteristics of axle shafts are tailored to meet the specific needs of each vehicle type, ensuring optimal performance and durability.

Can you describe the maintenance and repair considerations for axle shafts?

Maintenance and repair of axle shafts are essential to ensure the proper functioning and longevity of a vehicle’s drivetrain. Regular maintenance and timely repairs can help prevent costly damages and maintain optimal performance. Here’s a detailed explanation of the maintenance and repair considerations for axle shafts:

Maintenance Considerations:

To keep the axle shafts in good condition, the following maintenance practices are recommended:

- Inspections: Regularly inspect the axle shafts for signs of damage, such as cracks, bends, or excessive wear. Inspect the CV joints, bearings, seals, and retaining devices for leaks, deterioration, or looseness. Pay attention to any unusual noises, vibrations, or fluid leaks that may indicate potential issues.

- Lubrication: Ensure proper lubrication of the axle shafts, CV joints, and bearings as recommended by the vehicle manufacturer. Lubrication helps reduce friction, prevent excessive wear, and extend the lifespan of the components. Check the lubricant levels and quality during routine maintenance and top up or replace the lubricant as needed.

- Seal Protection: Inspect the seals around the axle shafts for damage or leaks. Damaged seals can allow contaminants, such as dirt, moisture, and debris, to enter the axle assembly, leading to premature wear and potential failure of the components. Replace damaged seals promptly to maintain proper protection.

- Boot Inspection: If the axle shafts have constant velocity (CV) joints, inspect the protective boots regularly. The boots cover the CV joints and keep them protected and lubricated. Look for any signs of cracks, tears, or leaking grease. Damaged boots should be replaced promptly to prevent dirt and moisture from entering the CV joints.

- Wheel Bearing Maintenance: If the axle shafts incorporate wheel bearings, follow the manufacturer’s recommendations for bearing maintenance. This may include periodic inspection, cleaning, re-greasing, or replacement of the wheel bearings to ensure smooth rotation and prevent excessive wear.

Repair Considerations:

If axle shaft issues are identified through inspections or during routine maintenance, the following repair considerations should be taken into account:

- Evaluation and Diagnosis: When encountering axle shaft problems, it’s important to accurately diagnose the issue before proceeding with repairs. This may involve a visual inspection, listening for abnormal noises, performing tests, or seeking professional assistance to identify the specific cause of the problem.

- Component Replacement: Depending on the nature and severity of the issue, repair options may vary. In some cases, replacing individual components such as CV joints, bearings, or seals may be sufficient. However, if the axle shaft itself is damaged or worn beyond repair, it may be necessary to replace the entire axle shaft assembly.

- Professional Expertise: Axle shaft repairs can be complex and require specialized knowledge and tools. It is often recommended to seek the assistance of a qualified mechanic or technician who has experience working with axle shafts. They can provide proper diagnosis, perform repairs accurately, and ensure the correct installation of components.

- Quality Parts: When replacing axle shaft components or the entire assembly, it is crucial to use high-quality parts that meet or exceed the manufacturer’s specifications. Using genuine or reputable aftermarket parts can help ensure proper fit, performance, and durability.

- Alignment and Calibration: After axle shaft repairs or replacements, it may be necessary to perform wheel alignment and calibration procedures to ensure proper suspension geometry, wheel balance, and drivetrain synchronization. This helps maintain vehicle stability, tire wear, and overall performance.

By following these maintenance practices and considering the appropriate repair steps, owners can help keep axle shafts in optimal condition, minimize the risk of failure, and ensure the reliable operation of the vehicle’s drivetrain.

What is the purpose of an axle shaft in a vehicle’s drivetrain?

An axle shaft plays a crucial role in a vehicle’s drivetrain by transmitting rotational power from the differential to the wheels. It serves as a mechanical link between the differential and the wheels, allowing the transfer of torque and enabling the wheels to rotate.

1. Power Transmission:

The primary purpose of an axle shaft is to transmit power from the differential to the wheels. In a rear-wheel-drive vehicle, the axle shafts connect the differential to the rear wheels, while in a front-wheel-drive vehicle, they connect the differential or transaxle to the front wheels. When the engine generates torque, it is transferred to the transmission or transaxle, and then to the differential. The differential splits the torque between the two axle shafts, which then deliver the power to the respective wheels. This allows the wheels to rotate and propel the vehicle forward or backward.

2. Wheel Support and Suspension:

Axle shafts also provide support for the vehicle’s wheels and are an integral part of the suspension system. They bear the weight of the vehicle and help maintain proper wheel alignment and geometry. Axle shafts are designed to withstand the vertical load exerted by the vehicle’s weight and the lateral forces encountered during turns or maneuvering. By providing structural support and connection between the wheels and the drivetrain, axle shafts contribute to the overall stability, handling, and control of the vehicle.

3. Differential Functionality:

Axle shafts are essential for the proper functioning of the differential. The differential allows the wheels to rotate at different speeds while maintaining power distribution. As the vehicle negotiates turns, the inside wheels travel a shorter distance than the outside wheels. The axle shafts, connected to the differential, enable this speed differentiation by allowing the wheels to rotate independently. This differential action helps improve maneuverability, reduce tire wear, and enhance traction by allowing the wheels to maintain proper contact with the road surface.

4. Torque and Load Handling:

Axle shafts are designed to handle the torque and loads generated by the engine and transmitted through the drivetrain. They are engineered to withstand the rotational forces and torsional stress, ensuring efficient power transfer to the wheels. Axle shafts are made from durable materials, such as steel or other high-strength alloys, to withstand these forces and provide reliable performance under various driving conditions.

In summary, the purpose of an axle shaft in a vehicle’s drivetrain is to transmit rotational power from the differential to the wheels. They enable power transfer, provide support for the wheels, contribute to the functionality of the differential, and handle the torque and loads generated by the drivetrain. Axle shafts are essential components that play a vital role in the overall performance, functionality, and stability of a vehicle.

editor by CX 2023-11-21

China 16 inch Folding ebike kit 36v 250w electric bicycle front rim rear motor wheel conversion kit with KT LCD5 display drive shaft adapter

Product Amount: yj-250

Battery Capability: optional

Electrical power Offer: Lithium Battery

Wheel Dimensions: sixteen

Show: Lcd

Motor Kind: brushless geared hub motor

Battery Place: optional

Bike Throttle: thumb throttle

Merchandise Title: 16

Open up dimensions: 100mm/front,135mm/rear

Building: Gear Drive

brake: Disc Brkae

IP: IP 54

pace: 20-35km/h

Max torque: 35N.m

max loading: 150kgs

cable place: Shaft Centre Appropriate

Certification: CE

Packaging Information: Common carton with foam

Port: ZheJiang /HangZhou

sixteen inch Folding ebike kit 36v 250w electrical bicycle front rim rear motor wheel converison kit with KT LCD5 screen Specification

| item | value |

| Place of Origin | China |

| ZheJiang | |

| Brand Name | mayebikes |

| Model Number | yj-250 |

| Battery Capacity | optional |

| Power Supply | Lithium Battery |

| Wheel Dimensions | 16″ |

| Display | LCD |

| Motor Type | brushless geared hub motor |

| Battery Place | optional |

| Bike Throttle | thumb throttle |

| Product Title | 16″ 36v 250w entrance rim and rear motor wheel kit |

| Open dimensions | 100mm/entrance,135mm/rear |

| Construction | Gear Generate |

| brake | Disc Brkae |

| IP | IP fifty four |

| speed | 20-35km/h |

| Max torque | 35N.m |

| max loading | 150kgs |

| cable area | Shaft Heart Proper |

| Certification | CE |

Driveshaft structure and vibrations associated with it

The structure of the drive shaft is critical to its efficiency and reliability. Drive shafts typically contain claw couplings, rag joints and universal joints. Other drive shafts have prismatic or splined joints. Learn about the different types of drive shafts and how they work. If you want to know the vibrations associated with them, read on. But first, let’s define what a driveshaft is.

transmission shaft

As the demand on our vehicles continues to increase, so does the demand on our drive systems. Higher CO2 emission standards and stricter emission standards increase the stress on the drive system while improving comfort and shortening the turning radius. These and other negative effects can place significant stress and wear on components, which can lead to driveshaft failure and increase vehicle safety risks. Therefore, the drive shaft must be inspected and replaced regularly.

Depending on your model, you may only need to replace one driveshaft. However, the cost to replace both driveshafts ranges from $650 to $1850. Additionally, you may incur labor costs ranging from $140 to $250. The labor price will depend on your car model and its drivetrain type. In general, however, the cost of replacing a driveshaft ranges from $470 to $1850.

Regionally, the automotive driveshaft market can be divided into four major markets: North America, Europe, Asia Pacific, and Rest of the World. North America is expected to dominate the market, while Europe and Asia Pacific are expected to grow the fastest. Furthermore, the market is expected to grow at the highest rate in the future, driven by economic growth in the Asia Pacific region. Furthermore, most of the vehicles sold globally are produced in these regions.

The most important feature of the driveshaft is to transfer the power of the engine to useful work. Drive shafts are also known as propeller shafts and cardan shafts. In a vehicle, a propshaft transfers torque from the engine, transmission, and differential to the front or rear wheels, or both. Due to the complexity of driveshaft assemblies, they are critical to vehicle safety. In addition to transmitting torque from the engine, they must also compensate for deflection, angular changes and length changes.

type

Different types of drive shafts include helical shafts, gear shafts, worm shafts, planetary shafts and synchronous shafts. Radial protruding pins on the head provide a rotationally secure connection. At least one bearing has a groove extending along its circumferential length that allows the pin to pass through the bearing. There can also be two flanges on each end of the shaft. Depending on the application, the shaft can be installed in the most convenient location to function.

Propeller shafts are usually made of high-quality steel with high specific strength and modulus. However, they can also be made from advanced composite materials such as carbon fiber, Kevlar and fiberglass. Another type of propeller shaft is made of thermoplastic polyamide, which is stiff and has a high strength-to-weight ratio. Both drive shafts and screw shafts are used to drive cars, ships and motorcycles.

Sliding and tubular yokes are common components of drive shafts. By design, their angles must be equal or intersect to provide the correct angle of operation. Unless the working angles are equal, the shaft vibrates twice per revolution, causing torsional vibrations. The best way to avoid this is to make sure the two yokes are properly aligned. Crucially, these components have the same working angle to ensure smooth power flow.

The type of drive shaft varies according to the type of motor. Some are geared, while others are non-geared. In some cases, the drive shaft is fixed and the motor can rotate and steer. Alternatively, a flexible shaft can be used to control the speed and direction of the drive. In some applications where linear power transmission is not possible, flexible shafts are a useful option. For example, flexible shafts can be used in portable devices.

put up

The construction of the drive shaft has many advantages over bare metal. A shaft that is flexible in multiple directions is easier to maintain than a shaft that is rigid in other directions. The shaft body and coupling flange can be made of different materials, and the flange can be made of a different material than the main shaft body. For example, the coupling flange can be made of steel. The main shaft body is preferably flared on at least one end, and the at least one coupling flange includes a first generally frustoconical projection extending into the flared end of the main shaft body.

The normal stiffness of fiber-based shafts is achieved by the orientation of parallel fibers along the length of the shaft. However, the bending stiffness of this shaft is reduced due to the change in fiber orientation. Since the fibers continue to travel in the same direction from the first end to the second end, the reinforcement that increases the torsional stiffness of the shaft is not affected. In contrast, a fiber-based shaft is also flexible because it uses ribs that are approximately 90 degrees from the centerline of the shaft.

In addition to the helical ribs, the drive shaft 100 may also contain reinforcing elements. These reinforcing elements maintain the structural integrity of the shaft. These reinforcing elements are called helical ribs. They have ribs on both the outer and inner surfaces. This is to prevent shaft breakage. These elements can also be shaped to be flexible enough to accommodate some of the forces generated by the drive. Shafts can be designed using these methods and made into worm-like drive shafts.

vibration

The most common cause of drive shaft vibration is improper installation. There are five common types of driveshaft vibration, each related to installation parameters. To prevent this from happening, you should understand what causes these vibrations and how to fix them. The most common types of vibration are listed below. This article describes some common drive shaft vibration solutions. It may also be beneficial to consider the advice of a professional vibration technician for drive shaft vibration control.

If you’re not sure if the problem is the driveshaft or the engine, try turning on the stereo. Thicker carpet kits can also mask vibrations. Nonetheless, you should contact an expert as soon as possible. If vibration persists after vibration-related repairs, the driveshaft needs to be replaced. If the driveshaft is still under warranty, you can repair it yourself.

CV joints are the most common cause of third-order driveshaft vibration. If they are binding or fail, they need to be replaced. Alternatively, your CV joints may just be misaligned. If it is loose, you can check the CV connector. Another common cause of drive shaft vibration is improper assembly. Improper alignment of the yokes on both ends of the shaft can cause them to vibrate.

Incorrect trim height can also cause driveshaft vibration. Correct trim height is necessary to prevent drive shaft wobble. Whether your vehicle is new or old, you can perform some basic fixes to minimize problems. One of these solutions involves balancing the drive shaft. First, use the hose clamps to attach the weights to it. Next, attach an ounce of weight to it and spin it. By doing this, you minimize the frequency of vibration.

cost

The global driveshaft market is expected to exceed (xxx) million USD by 2028, growing at a compound annual growth rate (CAGR) of XX%. Its soaring growth can be attributed to several factors, including increasing urbanization and R&D investments by leading market players. The report also includes an in-depth analysis of key market trends and their impact on the industry. Additionally, the report provides a comprehensive regional analysis of the Driveshaft Market.

The cost of replacing the drive shaft depends on the type of repair required and the cause of the failure. Typical repair costs range from $300 to $750. Rear-wheel drive cars usually cost more. But front-wheel drive vehicles cost less than four-wheel drive vehicles. You may also choose to try repairing the driveshaft yourself. However, it is important to do your research and make sure you have the necessary tools and equipment to perform the job properly.

The report also covers the competitive landscape of the Drive Shafts market. It includes graphical representations, detailed statistics, management policies, and governance components. Additionally, it includes a detailed cost analysis. Additionally, the report presents views on the COVID-19 market and future trends. The report also provides valuable information to help you decide how to compete in your industry. When you buy a report like this, you are adding credibility to your work.

A quality driveshaft can improve your game by ensuring distance from the tee and improving responsiveness. The new material in the shaft construction is lighter, stronger and more responsive than ever before, so it is becoming a key part of the driver. And there are a variety of options to suit any budget. The main factor to consider when buying a shaft is its quality. However, it’s important to note that quality doesn’t come cheap and you should always choose an axle based on what your budget can handle.

editor by Cx 2023-06-15

China OEM New design china 26 inch chainless CZPT inner 3 speed shaft drive mountain bike cycle for adults bicycle with high quality

Design Amount: Chief-five hundred

Fork Content: Aluminum Alloy

Rim Materials: Aluminum Alloy

Gears: 7 Speed

Gender: Guys

Fork Suspension: Yes

Gross Fat: 22.5kg

Internet Excess weight: 14.8kg

Wheel Size: 26

Body Materials: Aluminum Alloy

Frame Sort: Difficult Frame (Non-rear Damper)

Pedal Type: Common Pedal

Load Ability: 100KG

Frame: TDJDC 6061 Aluminum Alloy, Seamless

Fork: HL Aluminum alloy, with suspension

Transmission: TDJDC substantial-precision shaft push

Derailleur: CZPT 7-speed SG-3R40

Brake: F: HL HB-one hundred Hydraulic Disc Brake R: CZPT Roller Brake

OEM&ODM: Obtainable

Sample: Available

Situation: On-Highway

Combo Established Provided:

Foldable: NO

Training Wheels: NO

Application: road

Competition: Other

Packaging Specifics: Export common paper carton

Merchandise DESCRIPTIONS

Design :Leader-five hundred

Coloration

Green/Yellow/Purple

Software

Avenue

Frame

TDJDC 6061 Aluminum Alloy, Seamless

Certification

ISO9001, other

Fork

HL Aluminum alloy, with suspension

Warranty

5 many years

Transmission

TDJDC substantial-precision shaft push

Payment Time period

T/T, L/C

Derailleur

SHIMANO 7-velocity SG-3R40

MOQ

1 pcs

Brake

F: HL HB-one hundred Hydraulic Disc Brake R: CZPT Roller Brake

Port

Xihu (West Lake) Dis.,HangZhou

Gender

Adult

Rewards:1) Combating Mountain Resistance:Driving on different streets, forests. corners drifting, climbing, is suited to entire working day. TDJDC helps make the promise.

2) Appreciate the Glory Riding Knowledge:The special frame style, shaft travel and large-high quality automotive paint enable you appreciate the glory of riding knowledge.

In depth Pictures OTHER Merchandise OUR Firm Our Exhibitions Packing & Motorcycle Components Camshaft Timing Chain For SUZUKI DR250 Djebel 250 CZPT KLX250 KLX300 HONDA VT250 Delivery Our Service 1. OEM Producing welcome: Item, Package… 2. Sample buy is avaliabel. 3. We will reply you for your inquiry in 24 hours.4. following sending, we will track the items for you after every single 2 days, right up until you get the items. When you got the goods, take a look at them, and give me a opinions.If you have any queries about the issue, contact with us, we will offer you the fix way for you.

FAQ Q1. What is your phrases of packing?A: Generally, we pack our products in neutral white bins and brown cartons. If you have legally registered patent, we can pack the goods in your branded packing containers soon after obtaining your authorization letters. Q2. What is your terms of payment?A: T/T 30% as deposit, and 70% before shipping and delivery. We’ll show you the images of the goods and deals before you pay the stability. Q3. What is your conditions of shipping?A: EXW, FOB, CFR, 2571 low cost sizzling marketing atv forty four 250cc shaft drive higher good quality beauty offroad quad atv CIF. Q4. How about your shipping time?A: Generally, it will just take thirty to sixty times after obtaining your advance payment. The particular shipping time is dependent on the things and the quantity of your buy. Q5. Can you produce according to the samples?A: Of course, we can generate by your samples or complex drawings. We can build the molds and fixtures. Q6. What is your sample coverage?A: We can supply the sample if we have all set areas in inventory, but the consumers have to pay the sample price and shipping and delivery expense.Q7. Do you test all your merchandise ahead of shipping and delivery? A: Yes, we have a hundred% take a look at prior to delivery Q8: How do you make our organization long-expression and excellent partnership?1. We hold very good quality and aggressive value to ensure our buyers advantage 2. We respect each consumer as our friend and we sincerely do company and make pals with them, no matter exactly where they occur from.

HangZhou TDJDC Bicycle Science And Technological innovation Co., Ltd.Email: [email protected] No: 15917009187Whatsapp: 15917009187WELCOME TO OUR Factory: No.30-33 Office, Xihu (West Lake) Dis. Industrial Zone, Leliu, Xihu (West Lake) Dis., HangZhou City, 2571 1200W 48V Brushless Shaft Travel Electric Quad Kids ATV ZheJiang Province, P.R.C.(China)

Diverse components of the drive shaft

The driveshaft is the adaptable rod that transmits torque amongst the transmission and the differential. The term drive shaft may also refer to a cardan shaft, a transmission shaft or a propeller shaft. Parts of the generate shaft are diverse and contain:

The driveshaft is a versatile rod that transmits torque from the transmission to the differential

When the driveshaft in your automobile begins to are unsuccessful, you ought to seek out professional aid as quickly as possible to correct the problem. A broken driveshaft can usually be heard. This sounds appears like “tak tak” and is usually a lot more pronounced throughout sharp turns. Nevertheless, if you cannot hear the sounds although driving, you can check out the condition of the auto your self.

The push shaft is an crucial component of the car transmission technique. It transfers torque from the transmission to the differential, which then transfers it to the wheels. The method is complex, but still crucial to the correct performing of the automobile. It is the adaptable rod that connects all other parts of the drivetrain. The driveshaft is the most important part of the drivetrain, and comprehension its perform will make it less difficult for you to properly keep your vehicle.

Driveshafts are utilised in distinct vehicles, like front-wheel travel, 4-wheel drive, and entrance-motor rear-wheel generate. Push shafts are also utilised in motorcycles, locomotives and ships. Widespread front-engine, rear-wheel drive vehicle configurations are demonstrated under. The sort of tube employed depends on the measurement, speed and strength of the travel shaft.

The output shaft is also supported by the output hyperlink, which has two equivalent supports. The upper part of the push module supports a huge tapered roller bearing, while the opposite flange conclude is supported by a parallel roller bearing. This assures that the torque transfer in between the differentials is effective. If you want to learn far more about car differentials, read through this article.

It is also identified as cardan shaft, propeller shaft or push shaft

A propshaft or propshaft is a mechanical part that transmits rotation or torque from an engine or transmission to the entrance or rear wheels of a vehicle. Since the axes are not directly related to each other, it have to let relative movement. Since of its role in propelling the vehicle, it is crucial to comprehend the components of the driveshaft. Listed here are some typical types.

Isokinetic Joint: This sort of joint guarantees that the output velocity is the same as the input velocity. To achieve this, it need to be mounted back-to-again on a airplane that bisects the generate angle. Then mount the two gimbal joints again-to-back and change their relative positions so that the velocity modifications at 1 joint are offset by the other joint.

Driveshaft: The driveshaft is the transverse shaft that transmits electrical power to the front wheels. Driveshaft: The driveshaft connects the rear differential to the transmission. The shaft is portion of a push shaft assembly that involves a drive shaft, a slip joint, and a common joint. This shaft provides rotational torque to the travel shaft.

Dual Cardan Joints: This sort of driveshaft makes use of two cardan joints mounted back again-to-back again. The middle yoke replaces the intermediate shaft. For the duplex common joint to function correctly, the angle in between the enter shaft and the output shaft should be equivalent. Once aligned, the two axes will function as CV joints. An improved model of the twin gimbal is the Thompson coupling, which provides slightly a lot more performance at the cost of added complexity.

It transmits torque at different angles between driveline elements

A vehicle’s driveline consists of different factors that transmit electrical power from the engine to the wheels. This consists of axles, propshafts, CV joints and differentials. Jointly, these components transmit torque at different angles between driveline components. A car’s powertrain can only purpose correctly if all its parts perform in harmony. Without having these elements, energy from the motor would cease at the transmission, which is not the situation with a auto.

The CV driveshaft design offers smoother procedure at increased running angles and extends differential and transfer circumstance lifestyle. The assembly’s central pivot position intersects the joint angle and transmits clean rotational electricity and surface speed via the drivetrain. In some cases, the C.V. “U” connector. Push shafts are not the best option because the joint angles of the “U” joints are usually considerably unequal and can cause torsional vibration.

Driveshafts also have various names, which includes driveshafts. A car’s driveshaft transfers torque from the transmission to the differential, which is then dispersed to other driveline factors. A electrical power take-off (PTO) shaft is equivalent to a prop shaft. They transmit mechanical electricity to connected elements. They are vital to the efficiency of any auto. If any of these parts are destroyed, the whole drivetrain will not perform properly.

A car’s powertrain can be sophisticated and tough to preserve. Incorporating vibration to the drivetrain can result in premature wear and shorten total lifestyle. This driveshaft idea focuses on driveshaft assembly, operation, and routine maintenance, and how to troubleshoot any issues that might crop up. Introducing proper solutions to ache factors can lengthen the existence of the driveshaft. If you might be in the marketplace for a new or employed car, be certain to read this report.

it consists of a number of parts

“It is made up of several areas” is 1 of 7 little prints. This term consists of ten letters and is one of the hardest phrases to say. Nonetheless, it can be explained simply by evaluating it to a cow’s kidney. The cocoa bean has several areas, and the inside of of the cocoa bean prior to bursting has distinctive traces. This write-up will talk about the various elements of the cocoa bean and give a entertaining way to understand a lot more about the word.

Substitute is pricey

Replacing a car’s driveshaft can be an high-priced affair, and it truly is not the only component that demands servicing. A broken generate shaft can also lead to other issues. This is why getting estimates from various mend stores is important. Often, a basic restore is less expensive than changing the whole unit. Shown underneath are some ideas for preserving income when changing a driveshaft. Detailed under are some of the expenses associated with repairs:

First, understand how to figure out if your car demands a driveshaft alternative. Damaged driveshaft parts can trigger intermittent or deficiency of power. Moreover, improperly put in or assembled driveshaft factors can lead to problems with the everyday procedure of the vehicle. Each time you suspect that your automobile wants a driveshaft repair, look for expert guidance. A skilled mechanic will have the expertise and expertise essential to correctly resolve the problem.

Second, know which elements need servicing. Examine the u-joint bushing. They ought to be free of crumbs and not cracked. Also, examine the center assistance bearing. If this part is damaged, the total push shaft requirements to be replaced. Ultimately, know which elements to replace. The routine maintenance value of the drive shaft is significantly reduced than the maintenance price. Last but not least, establish if the fixed driveshaft is appropriate for your automobile.

If you suspect your driveshaft requirements services, make an appointment with a repair store as shortly as feasible. If you are encountering vibration and rough using, driveshaft repairs may be the best way to stop pricey repairs in the long term. Also, if your automobile is encountering unusual noise and vibration, a driveshaft fix could be a rapid and simple solution. If you do not know how to diagnose a difficulty with your automobile, you can get it to a mechanic for an appointment and a quote.